Bonneted Mercedes shows up well on site

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

BONNETED SIX-WHEEL on/ off site tippers are becoming popular with the specialist UK operators requiring a heavyduty site vehicle capable of working on normal roads within C & U Regulations. Magitus Deutz started the ball rolling with its 6x4 and 6x6 models and now other, notably, foreign manufacturers are vying for their share of the estimated, 1,400 vehicles-a-year market During a recent demonstration, staged by Thos W. Ward Ltd, I took the opportunity briefly to evaluate the on-site performance of one of the relative newcomers in the field, the Mercedes-Benz LK2624 6x6 on/off site tipper.

The vehicle, complete with Telehoist lOcum (13 cuyd) dumper body and frontmounted ram, has an unladen weight of 11.7 tonnes (11.6 tons) permitting a maximum payload of 14.7 tonnes (14.5 tons) within the vehicle's plated design weight of 26.4 tonnes (26 tons). On the road, payload capacity is reduced by 2 tonnes (2 tons) to comply with the maximum 24.4 tonnes (24 tons) gvw imposed by Construction and Use Regulations.

The vehicle was slotted into normal operation at the Reservoir Aggregates Ltd quarry at Staines, Middlesex, and was employed to transport "as-dug" ballast from a stockpile to a "drive-over" ground hopper about 1.9km (1.2 miles) away. The ground hopper was at the top of a 1 in 10.9 climb.

Low floor-line

The normal-control layout of the Mercedes cab makes for a low floor-line and easy cab entry and exit. However, the large diameter steering-wheel makes it necessary to dip your knees or splay your legs when taking the driver's seat. The large wheel is required to meet German regulations concerning steering-wheel efforts necessary to manoeuvre the vehicle should the power assistance fail. Interior trim is neat and functional with both the driver and passenger having clothcovered seats. The driver is able to adjust the position of the seat cushion and squat to personal preference.

The instruments and gauges are well placed for the driver though the large, clumsy-looking handbrake lever takes getting used to. The lever, which protrudes from beneath the dash between the driver and engine cover, is pulled on and then moved to the nearside to engage on the ratchet, which holds the brakes on. To release, the lever is shifted to the offside and pushed home into the dash.

Apart from the usual selection of gauges, the Mercedes is fitted with a wide range of "idiot lights" backed up by warning bleepers for failing air-pressure or engine overheating.

Driving the Mercedes LD2624 is simple, and provided one follows a simple gearchange procedure even the unfamiliar driver should warm to the action of the six-speed gearbox.

The two-speed transfer box has low (on-site) and high (onroad) ratios. I engaged the low ratio although the good prevailing conditions would probably have allowed the high gear to be used without detriment to overall performance. The transfer-box select lever is between the driver and passenger seats.

Best result

Changing-up through the sixspeed gearbox, the best result is achieved by allowing the engine revs to top 2,200rpm before disengaging, and then engaging the next higher ratio as the rev-counter needle passed 1,500rpm. The reverse applies to down-changing, the disengage shift taking place with the engine at 1,500rpm and then revving the engine to 2,200rpm with neutral engaged before smartly selecting the lower ratio. It is essential that the ratio is engaged with a smart, deliberate action once the required engine speed has been reached, otherwise a poor or even missed change will result.

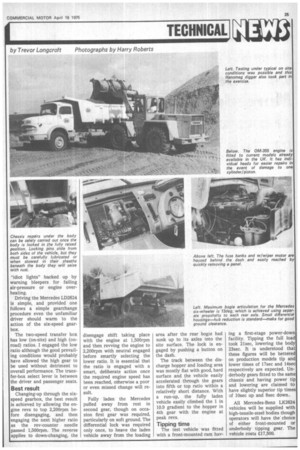

Fully laden the Mercedes pulled away from rest in second gear, though on occasion first gear was required, particularly on soft ground. The differential lock was required only once, to heave the laden vehicle away from the loading area after the rear bogie had sunk up to its axles into the site surface. The lock is engaged by pushing a button on the dash.

The track between the discharge hopper and loading area was mostly flat with good, hard surface and the vehicle easily accelerated through the gears into fifth or top ratio within a relatively short distance. With a run-up, the fully laden vehicle easily climbed the 1 in 10.9 gradient to the hopper in 4th gear with the engine at peak revs.

Tipping time

The test vehicle was fitted with a front-mounted ram hay ing a first-stage power-down facility. Tipping the full load took 21sec, lowering the body 23sec. It is understood that these figures will be bettered on production models tip and lower times of 17sec and 14sec respectively are expected. Underbody gears fitted to the same chassis and having power tip and lowering are claimed to have slightly superior tip times of lOsec up and 8sec down..

All Mercedes-Benz LK2624 vehicles will be supplied with high-tensile-steel bodies though operators will have the choice of either front-mounted or underbody tipping gear. The vehicle costs £17,500.