THE GARRETT UNDERTYPE STEAM WAGON.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

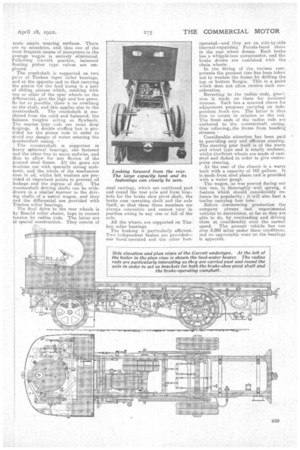

A 6-ton Machine with Pressed-steel Frame, Unit Construction of Engine, Countershaft and Feed Pump, Two-speed Gear and Dead Rear Axle.

THE UNDERTYPE steam wagon has achieved considerable popularity amongst a large number of users. It presents cerium advantages, such as short overall length and consequent greater manteuvranility than the overtype, although, unless particular attention is paid to the design, the accessibility may not be so good.

On March 28th we published the first illustrated description of the new Garrett wagon and gave its main features in brief; but we consider the wagon worthy of even a more lengthy description than that which we can give it now. It is particularly interesting, as it embodies certain features which have not yet been , incorporated in other undertvpes. The chief of these is the two-Speed gear. On top gear the wagon is capable of taking A mad of 6 tons up a hill of 1 in 8, but there are times when a low gear is desirable. These are especially when the wagon is travelling on soft country roads or pulling out of quarries, etc., where the gradients are very steep and the surface bad.

The use of a pressed-steel channel section frame has enabled the weight of this member to be scientifically distributed, and thus, while being lighter, it is probably stronger than the ordinary girder or built-up frame, whilst provision has been made for any slight. frame flexion which may occur, the engine, counter

shaft and feed pump assembly being three-point suspended. Incidentally, this whole assembly can be dropped out in one hour.

One of the chief points in the new wagon is that the designers have considered the question of obtaining a high average speed rather than extremes of speed. With this in view, in spite of the fact that the Garrett boiler which will be fitted to the production model is larger than that used on any other undertype, and that the vehicle has a powerful engine with two high-pressure cylinders of 4i-in. bore and 7i-in. stroke, the final gear ratio is comparatively low, being 12 to 1. It must, not

be thought, however, that the wagon is slow.. It can reach 25 m.p.h. compara-Lively easily, but its average speed is in the neighbonrhood of 15 m.p.h., and from tests which we have conducted with it, it is very nearly as fast on hills as on the level.

Another important point is the simplicity of the control. It has been made,

so far as possible, to resemble that of a petrol wagon. For instance, there is a pedal throttle control similar to the accelerator of a petrol vehicle, further steam control being given by the expansion gear operated by a lever at the right of the driver, whilst the two-speed gear is operated by a lever at the left of 'the driver, the engine being stopped while a change is effected.

The boiler is designed for a working pressure of 250 lb. per sq. in., and is of the vertical water-tube type tested hydraulically before use to 5t-'d lb. per sq. in. It is fired through a chute in the footplate in a somewhat similar manner to the Atkinson. At one side of the boiler is a large cover plate, which can be removed in order to clean the inside shell and the flue system. At the opposite side of this cloor'is a smaller one, through which the tubes can be expanded if necessary, and through which also that side of the boiler can be cleaned.

Situated in the s.mokebox is an efficient steam superheater made of steel tubes expanded into cast-steel headers. The surface is sufficient to heat the steam to 100 degrees F. To the left, of the boiler is the tubular type feed-water heater. An injector is provided and is situated slightly away from the boiler, 'so that it cannot become hot and refuse to work. The water-feed pump, although it is. a complete unit and situated outside the chassis frame, is bolted up to the engine and countershaft casing. It is of the eccentric plunger type and is driven througha 3 to 1 reduction gear from a pinion at one end of the crankshaft. The pump is particularly accessible, and, by throwing the engine out of gear, it can be used when the wagon is stationary. The control for it is fitted to the steering column.

We have already referred to the engine, but must mention that it, is of the horizontal, double-acting type with Joy radial valve gear. It has large casehardened steel pins, and everywhere pre

seats -ample wearing surfaces. There are no eccentrics, and thus one of the most frequent causes of annoyance in the average wagon is entirely eliminated. Following (Jarrett practice, balanced floating piston type valves are employed. ,

The crankshaft is supported on two pairs of Timken taper roller bearings, and at, the opposite end to that carrying the pinion for the feed pump is a pair of sliding pinions which, meshing with. one or other of the spur wheels on the differential, give the high and low gears. So far as possible, there is no overhang on the shaft, and this applies also to the

qountershaft. The crankshaft is maChimed from the solid and balanced, the balance weights acting as flywheels. q, he marine type rods arc stout drop fergings. A double stuffing box is prettied for the piston rods in order to void any danger of water entering the 3

untersliaft casing. .

The couatershaft is supported in / I eavy spherical bearings, one fastened nd the other free to move endwise, and thus to allow for any flexion of the pressed steel frame. All the gears are machine cut with specially strong stubteeth, and the, whole of the mechanism inns in oil, whilst felt washers are provided at important points to prevent oil leakage and the ingress of dirt. The ountershaft driving shafts can be withyawn it a similar manner to the drivg shafts of a petrol wagon, and they nd the differential are provided with • imken roller bearings. The final drive to the rear wheels is y Renoir] roller chains, kept in correct. itsion by radios rods. The latter are I special construction. They consist of

steel castings, which are continued past and round the rear axle and form brackets for the brake shoe pivot shaft, the brake cam operating shaft and the axle itself, so that these three members are always concentric and cannot vary in position owing to any rise or fall of the axle.

All the wheels are supported on Tinken roller bearings. The braking is particularly efficient Two independent brakes are provided— one hand.operated and the other foot operated—and they act on side-by-side internal-expanding Feroda-faced shoes in the rear wheel drums. Each brake has a whippie-tree compensator, and the brake drums are combined with the chain wheels.

In the fitting of the various components the greatest care has been taken not to weaken the frame by drilling the top or bottom flanges. This is a point which does not often receive such consideration.

Reverting to the radius rods, provision is made on these for torsional stresses. Each has a screwed sleeve for adjustment purposes carrying on independent front eye. The latter is thus free to rotate in relation to the rod. 'rho front ends of the radius rods am anchored to the countershaft casing, thus relievingAbe frame from bending stresses. , Considerable attention has been paid to providing easy and efficient steering. The steering gear itself, is of the worm and wheel type and is totally enclosed, Whilst theifront wheels are made of caststeel and dished in order to give centrepoint steering. At the rear of the chassis is a water tank with a capacity of 163 gallons. It is made from steel plates and is provided with a water gauge.

The wagon, as was proved during our i test run, s thoroughly well sprung, a feature which should considerably enhance its popularity; t. willalso haul a. trailer carrying four tons.

Before commencing production the company always test experimental vehicles to destruction, so far as they are able to do, by overloading and driving them at. considerably over the normal speed. The present vehicle has run over 3,000 miles under these conditions, and no appreciable wear on the bearings is apparent.