TN SHOW COMES ALIVE

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

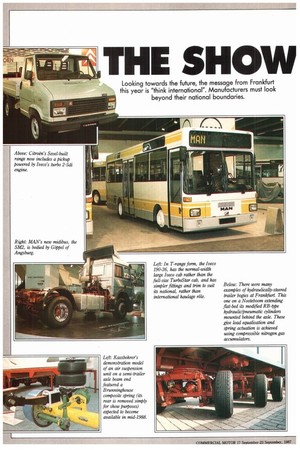

Looking towards the future, the message from Frankfurt this year is "think international". Manufacturers must look beyond their national boundaries.

• Commercial vehicle and component manufacturers who want to prosper in the 1990s must look beyond their national borders. That is the loudest and clearest message from this year's Frankfurt Show. The 52nd IAA (Internationale Automobil-Ausstellung) is probably more genuinely "internationale" than any of the previous 51 shows.

From mighty Daimler-Benz, still the world's most prolific manufacturer of trucks over six tonnes GVW and as usual the biggest IAA exhibitor, to diminutive Steyr of Austria and even our own ERF; they are all looking to play on more of an international stage than ever before.

The new, Spanish-built, front-wheel-drive Mercedes vans and chassis cab which were quietly unveiled amid mystery and some confusion at the Barcelona Show in May (CM 9 May) make their first public appearance outside Spain.

Germans are not used to seeing Mercedes vehicles built outside Germany on display at the Frankfurt Show, which explains why Gerhard Liener, head of the newly-formed Daimler-Benz Commercial Vehicle Division, was at pains to emphasise the high standard of quality control applied to the MB100 range and that "the important label does not read 'made in Spain' or `made in Germany' but 'made by Daimler-Benz'.

Liener also threw some light on his company's hithertounclear plans for selling the new vans outside Spain. From autumn they will go on sale in West Germany, Belgium, France, Italy, the Netherlands and Austria, as well as in Spain. There are no plans, it seems, for Mercedes-Benz (UK) to take right-hand-drive versions of the stylish Spanish van, although a significant phrase used by Liener in listing the countries for which it is destined is "for the time being".

Liener's boss, Edzard Reuter, chairman of the board of management of Daimler-Benz AG, talked about vans too, and about Spain. He confirmed, as we have reported several times during the past year or so, that Daimler-Benz is negotiating with Mitsubishi over jointly developing and building a van in Spain. What came as a surprise was that Reuter revealed that not just one van — the Mitsubishi L300-based MB80 — is under discussion, but a complete range of different sizes, and that part of the quid pro quo for Daimler-Benz is that Mitsubishi will sell the complete range of Mercedes vehicles, cars and commercials, in Japan.

Reuter had one more revelation up his sleeve. He is bidding to acquire 5% of the French state-owned Matra electronics and motor components group, which is due to be sold off shortly as part of the French government's moves to "privatise".

INDEPENDENT

During the odd quiet moments at the show, engineers from Daf and Enasa could be seen scratching their heads in the vicinity of the Steyr-DaimlerPuch stand. They were trying to figure out how a company of this size — no more than about 3,500 Steyr trucks will be built this year, virtually all of them for the firm's domestic Austrian market — can afford to design, develop and build its own cab for a range of 9-16 tonners.

Although each of their annual production totals is several times that of Steyr's, Daf and Enasa long ago reached the conclusion that neither company could individually justify such cost, which is why Cabtec was formed with the resultant new Daf and Pegaso trucks.

It is estimated that the minimum cost of fully developing a new steel cab for mediumweight trucks these days is at least 220 million.

Steyr has been even more successful than it expected in improving its market share in Austria with the new middleweights, which were intro duced there in March last year. Now the company, which, apart from OAF (in effect an MAN subsidiary) is Austria's only commercial vehicle manufacturer and is majority-owned by the national bank, is out to sell its middleweight in other European countries including, possibly, the UK.

There has been speculation that ERF is negotiating to use the Steyr cab on a new range of Sandbach-built, under-16 tonnes GVW trucks, with Steyr in return using the ESeries cab on its heavyweights.

JOINT VIRITURRS ERF's chairman, Peter Foden, flatly denies it. Steyr says it has been talking about joint ventures with ERF, and with "a lot of other manufacturers".

A Steyr spokesman in Frankfurt last week went further to say that the possibility oi simply selling Steyr-badged, right-hand-drive versions of the new middleweight, through dealers culled mainly from the Bedford, Iveco Ford and Leyland Daf shakeouts, had not been ruled out.

The stylish, new Steyr cab probably would attract some British operators, but they would need fully convincing that the small Austrian manufacturer could provide an adequate standard of service and parts support for its chassis, especially for Steyr's own 6.6-litre, six cylinder engine. Two versions are fitted. The naturally-aspirated unit, rated at 100kW (136hp) DIN at 2,400mm, and the turbocharged version at 130kW (177hp) at the same speed. The N/A engine chives through a Steyr five-speed synchromesh gearbox, the turbocharged unit through a ninespeed ZF 9S 109.

GRP EXPERTISE ERF has no vehicles on display at Frankfurt, but it is represented there through its subsidiaries, ERF Plastics and ERF Technology.

"Manufacturers throughout Europe are realising the vast benefits of glass-reinforced plastics," says Peter Foden, optimistically.

ERF is at the IAA to try to sell its expertise in this field, indeed ERF Technology, the newest member of the ERF group, was recently established specifically for this purpose.

This Frankfurt show is exceptionally important for Detroit Diesel Allison, the General Motors diesel engine and automatic gearboxmanufacturing subsidiary. Not only did it display its all-new, electronically-controlled 60Series engine (CM 14 March) outside the United States for the first time, but also unveiled its WT (World Transmission) automatic gearbox which is scheduled to go into production in 1990.

Although DDA makes more fully-automatic commercial vehicle gearboxes than any other company in the world (last year 84,000 Allison transmissions were sold, 70,000 of them for on-road vehicles), less than 15% of that total is sold outside North America.

One of the GM division's chief objectives with the WT gearboxes is to win back sales from its many rivals outside the USA and Canada.

The WT is the same basic type of gearbox as Allison's current HT and MT ranges — that is, it is of the internal multi-plate clutch type with torque-converter drive from the engine.

In place of the four gear ratios of the current Albons, however, the WT has six, which the company claims leads to typical on-road fuel economy improvements of 510%, depending on the vehicle's duty cycle.

DDA says that extensive customer research shows better fuel economy is the top priority for operators of onroad vehicles with automatic gearboxes. They also want better low-speed cooling and better packaging so the gearbox takes up less space.

The WT has been designed to satisfy all these requirements. It has 25% fewer parts than current Allisons; is 15% lighter; 21% shorter in length; and requires 75% fewer service tools, and although DDA will not yet put a figure on it, its selling price should not be as discouragingly high as the current range.

DUBIOUS DISTINCTION

The MT and HT transmissions have the dubious distinction of using the world's largest single-piece die casting for their housings, and it is extremely expensive. The new one is smaller and cheaper, and DDA has made many other manufacturing economies in its new WT plant.

Why introduce a new product so far in advance of its start-of-production date? DDA says it wants to give its existing and potential new customers plenty of time to en

gineer the WT option into their new chassis.

The Series 60 engine on display at Frankfurt is the 298kW (400hp), 2,100rpm version of the 12.7 litre engine. DDA has no firm European orders for the advanced four-stroke, OHC engine yet, but Kassbohrer has just joined the shortlist of manufacturers who will soon have an engine with which to conduct trials, the 11.1 litre version.

VOLVO IN GERMANY

Volvo announced it is to begin selling its buses and coaches in West Germany for the first time. When sales begin next year, Austria will then be the only West European country in which they are not available.

The company will concentrate initially on selling its BlOM chassis. Marketing director Jurgen Bahr says: "West Germany is of great importance as a transit country for our coaches and we have already built up an extensive service network with coach parts and coach knowledge to assist transit traffic.

"Volvo already has a major share of the West German market for heavy trucks and would now like to see Volvo coaches enter this interesting market and offer an alternative to the domestic manufacturers who totally dominate it."

• TANKER TRAGEDY Much of the technical talk at Frankfurt was concerned with the recent West German tanker tragedy at Herbom, where an articulated petrol tanker overturned and the ensuing explosion devastated a small town as burning fuel spread quickly through an underground drainage system.

Because the tractive unit which crashed was a Mercedes equipped with an EPS gearchange system, some sections of the German media have put a question mark over electronic gearchange systems of this type. The question repeatedly asked is would the driver of the tanker have been able to engage a lower gear and control the vehicle on the bend instead of fatally running out of control if the Mercedes had had a conventional mechanicalshift system?

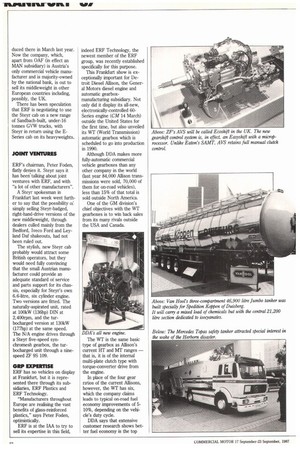

Senior engineers like MAN's technical director, Klaus Schubert, are convinced that the EPS system had little or nothing to do with the accident. Whatever the eventual repercussions of the disaster in terms of measures to improve tanker safety in West Germany and the rest of the EEC, it seems likely that the current quickening pace of development of electronicallycontrolled gearshift systems will continue unabated.

ZF has added the AVS (automatisierte vorwahl schaltung) to its Easyshift system. AVS uses the same gearboxmounted electro-pneumatic valves as Easyshift but additionally has a micro-processor to advise the driver on the gear to select for the best fuel economy, or, when the system is in automatic mode, to select that gear as soon as the clutch is disengaged.

We tried AVS, which will be called Ecoshift in the UK, over a short test route around Frankfurt, in a Kassbohrer S215HD coach powered by a Mercedes OM 422A, 260kW (350hp) vee-eight engine. The gearbox on which the AVS system was fitted was a six-speed synchromesh, Ecomid 6S150C.

The first impression of AVS is that it is very similar to Scania's CAG system, with a rotary switch to select automatic or manual mode, or reverse; and a dashboardmounted small digital display to show the gear selected and how many gears may be shifted up or down.

The AVS shift lever, however is more like the EPS unit used by Mercedes, and operates in the same plane, forward for higher gears, back for lower gears.

AVS is not like Eaton's SAMT: the clutch has to be manually disengaged before any gearchange will take place. ZF says that one of its major advantages compared with Scania's CAG is that it will never select neutral, unless the driver positively requests it to do so by holding the selector lever to the nearside.

We tried hard to fool the system by letting up the clutch pedal too quickly and, while the wrong gear could be selected, causing some unpleasant transmission jolts, we never did end up in unwanted neutral.

ZF says the AVS system is scheduled to become available "next year". It is not yet clear what its cost will be.