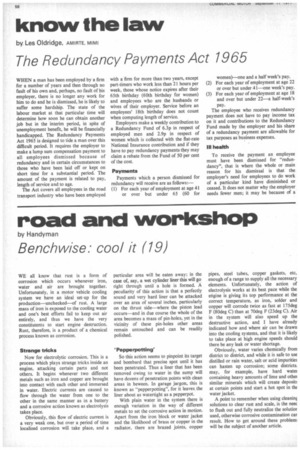

road and workshop

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

by Handyman

Benchwise: cool it (19)

WE all know that rust is a form of corrosion which occurs whenever iron, water and air are brought together. Unfortunately, in a motor vehicle cooling system we have an ideal set-up for the production—unchecked--of rust. A large mass of iron is exposed to the cooling water and one's best efforts fail to keep out air entirely, and thus we have the very constitutents to start engine destruction. Rust, therefore, is a product of a chemical process known as corrosion. particular area will be eaten away; in the case of, say, a wet cylinder liner this will go right through until a hole is formed. A peculiarity of this action is that a perfectly sound and very hard liner can be attacked over an area of several inches, particularly on the thrust side—where the piston lead occurs—and in due course the whole of the area becomes a mass of pin-holes, yet in the vicinity of these pin-holes other areas remain untouched and can be readily polished.

Strange tricks

Now for electrolytic corrosion. This is a process which plays strange tricks inside an engine, attacking certain parts and not others. It begins whenever two different metals such as iron and copper are brought into contact with each other and immersed in water. Electric currents are caused to flow through the water from one to the other in the same manner as in a battery and a corrosive action known as electrolysis takes place.

Obviously, this flow of electric current is a very weak one, but over a period of time localized corrosion will take place, and a

'Pepperpotting'

So this action seems to pinpoint its target and bombard that precise spot until it has been penetrated. Thus a liner that has been removed owing to water in the sump will have dozens of penetration points with clean areas in beween. In garage jargon, this is known as "pepperpotting", for it leaves the liner about as watertight as a pepperpot.

With plain water in the system there is enough variation in the way of different metals to set the corrosive action in motion. Apart from the iron block or water jacket and the likelihood of brass or copper in the radiator, there are brazed joints, copper pipes, steel tubes, copper gaskets, etc, enough of a range to supply all the necessary elements. Unfortunately, the action of electrolysis works at its best pace while the engine is giving its top performance at the correct temperature, as iron, solder and copper will corrode twice as fast at 175deg F (80deg C) than at 70deg F (23deg C). Air in the system will also speed up the destructive action, and I have already indicated how and where air can be drawn into the cooling systems, and that it is likely to take place at high engine speeds should there be any leak or water shortage.

Obviously, water varies chemically from district to district, and while it is safe to use distilled or rain water, salt or acid impurities can hasten up corrosion; some districts, may, for example, have hard water containing heavy amounts of lime and other similar minerals which will create deposits at certain points and start a hot spot in the water jacket.

A point to remember when using cleanini solutions to clear rust and scale, is the neec to flush out and fully neutralize the solutior used, otherwise corrosive contamination car result. How to get around these problem: will be the subject of another article.