'CMf MERCEDES -BENZ LPS 2024

Page 51

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

',77/71 YORK 38-TON-GROSS ARTK and operational by Gibb Grace, DAuE, CEng, MIMech E

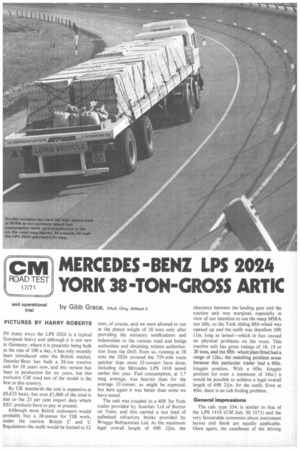

trial PICTURES BY HARRY ROBERTS

IN many ways the LPS 2024 is a typical European heavy and although it is not new in Germany, where it is presently being built at the rate of 100 a day, it has only recently been introduced onto the British market. Daimler-Benz has built a 38-ton tractive unit for 10 years now, and this version has been in production for six years. but this exclusive CM road test of the model is the first in this country.

By UK standards the unit is expensive at £8,625 basic, but over £1,000 of the total is due to the 23 per cent import duty which EEC products have to pay at present.

Although most British customers would probably buy a 38-tonner for TIR work, under the current British C and U Regulations the outfit would be limited to 32 tons, of course, and we were allowed to run at the plated weight of 38 tons only after providing the statutory notifications and indemnities to the various road and bridge authorities and obtaining written authorization from the DoE. Even so, running at 38 tons the 2024 covered the 729-mile route quicker than most 32-tonners have done, including the Mercedes LPS 1418 tested earlier this year. Fuel consumption, at 5.7 mpg average, was heavier than for the average 32-tonner, as might be expected, but here again it was better than some we have tested.

The unit was coupled to a 4011 3in York trailer provided by Autofair Ltd of Burton on Trent, and this carried a test load of palletized refractory bricks provided by Wraggs Refractories Ltd. At the maximum legal overall length of 4911 2+in, the

clearance between the landing gear and the tractive unit was marginal, especially in view of our intention to use the steep MIRA test hills, so the York sliding fifth-wheel was opened up and the outfit was therefore 50ft 1 lin. long as tested—which in fact caused no physical problems on the route. This tractive unit has gross ratings of 18, 19 or 20 tons, and the fifth -wheel plate fitted had a range of 12th.; the matching problem arose because this particular trailer had a 40th. kingpin position. With a 60in. kingpin position (or even a minimum of 54in.) it would be possible to achieve a legal overall length of 4911 2lin. for the outfit. Even at 40in. there is no cab fouling problem.

General impressions

The cab, type 354, is similar to that of the LPS 1418 (CM July 30 1971) and the very favourable comments about instrument layout and finish are equally applicable. Once again, the excellence of the driving

seat and the positioning of the controls were (with one exception, detailed later) impressive. I found the pedals ideally placed in relation to the seat, which is adjustable fore and aft, up and down, and has adjustable rake for cushion and squab.

Clutch load is pleasantly light and its travel is about 4in.; the brakes, again, are light but with increasing response with travel, a feel which promotes a great feeling of security and would be difficult to improve upon. The accelerator is very light and has the shortest travel I have encountered; it is hinged below floor level and requires only the ball of the foot to operate it. At full throttle, which is most of the time, the foot sits almost flat on the floor. No effort is needed to hold the accelerator down and as the angle of the ankle is very natural one's leg is completely relaxed even after many hours. The steering wheel is large, if anything perhaps a bit too large, creating a tendency to hold it on the spokes rather than the rim.

There was absolutely no vibration of any sort and fingers, wrists and arms were fatigue-free at the end of the day. The power steering, fitted as standard, was perfectly matched to the vehicle, and at four turns from lock to lock steering was quick and responsive with no tendency to wander.

The gear lever sits well over towards the driver but fifth gear position, which is away from the driver and forward, I found right at the end of my reach. This proved a continual irritation as most sections of the route only required 6th, 5th and 4th high and low.

Over and above these very important points was the low general noise level in the cab. The engine which rarely went above 2,400 rpm was very effectively silenced and there were no other obvious noises to distract. There was a complete absence of transmitted road noise even on the roughest surfaces, there were no irritating rattles or squeaks in the bodywork and surprisingly no wind noise in spite of having fresh air vents at floor level open, the roof vent open and the quarter lights open. No radio was fitted but one felt that here was a vehicle that needed one—not least because you would be able to listen to it properly.

The ride at all times was outstandingly good, on motorways especially, and was no doubt due partly to the long wheelbase—llft 10in, outer axle spread—and the fact that the fifth wheel was positioned 2ft 4in. ahead of the rear axle. First and third axles are fitted with telescopic dampers and anti-roll bars. There seemed to be very little pitch or bounce even when particular attention was paid to checking these features.

Acceleration and braking Acceleration and braking performance was checked at MIRA but we spent longer than usual trying to determine the best method of obtaining maximum acceleration. I suppose each driver has his own ideas on this and I for one usually start in second gear and miss out some of the high/low changes. However, on this occasion we had time to try different procedures and I arn bound to say that, apart from the benefit of starting in 2nd low, it proved quicker to ust every ratio in the 12-speed splitter box. still think my system would be faster witlsome gearbox /two-speed axle arrangemerth but with the ZF splitter box fitted it was not The vehicle had covered only some 5,00( miles from new and it was quicker to doubk declutch in the lower gears, but change: from 4th to 5th and from 5th to 6th coulc be made very quickly using the synchro.

The splitter gear was preselected by button mounted on the gear lever ant actuated by pushing the clutch to the floor Effortless, noiseless splits could 1)1 guaranteed on every occasion. Finally, thi choice of ratios was so good that it was folly to miss one out; each change gave a drop of some 300 rpm and kept the engine in the full-power range all the time. The acceleration figures obtained are comparable with many current 32-tonners and certainly we kept up with the traffic under all conditions.

Braking results were very similar to those for the lighter LPS 1418, at 29ft from 20 mph and 61ft from 30 mph. The secondary system gave a very satisfactory 43 per cent. The 2024 model has a full air three-line system, whereas the LPS 1418 has an air /hydraulic system. The long descents after Carter Bar caused the brake linings to heat up to the point where we could smell them in the cab, even though the exhaust brake was operating. To be fair, we were probably pushing the vehicle harder than an

operator would do. As it was, by using the exhaust brake continuously for all long descents, and the footbrake to pull the vehicle down to the required speed at intervals, we completed even the severest descents without any suspicion of brake fade.

Hill performance

Due mainly to the excellent matching of the gearbox and the optional 6.46 : l rear axle ratio (the other choices are 5.26 and 5.77), the vehicle's performance on hills was commendable considering that it was carrying very nearly a 26-ton pay-load. Although the rated top speed at 2,200 rpm is only 52 mph, slight downgrades allowed 2,500 rpm (57 mph) to be reached without effort and parts of MI and M6 were covered at an average of 51 mph. Even the two steep sections of M6, between intersections 36 and 37. and 38 and 39, were completed at 34 and 33 mph respectively. The technique. as I game to learn, was to change down meticulously at 1,900 rpm and not to be tempted to -hang on" to a gear. In this way the correct gear for the gradient was soon found and maximum possible speed maintained.

As an indication of the improvement this

gearbox made over that of the LPS 1418, Carter Bar was climbed in 7min 57sec, very nearly one minute quicker. Also the 2024 climbed Riding Mill (1-in-5.25 maximum gradient) and Castleside hills in 1st high. whereas these had to be by-passed on the LPS 1418 test. On the test hills at MIRA the 2024 restarted on the 1-in-6 hut failed on the 1-in-5 due to clutch slip.

continued on page 57