New high-articulation tandems from Ford

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

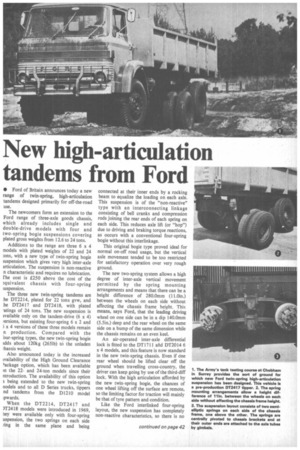

• Ford of Britain announces today a new range of twin-spring, high-articulation tandems designed primarily for off-the-road use.

The newcomers form an extension to the Ford range of three-axle goods chassis, which already includes single and double-drive models with four and two-spring bogie suspensions covering plated gross weights from 12.6 to 24 tons. Additions to the range are three 6 x 4 models with plated weights of 22 and 24 tons, with a new type of twin-spring bogie suspension which gives very high inter-axle articulation. The suspension is non-reactive n characteristic and requires no lubrication. The cost is £250 above the cost of the !,quivalent chassis with four-spring ;uspension.

The three new twin-spring tandems are he DT2214, plated for 22 tons gvw, and .he DT2417 and DT2418, with plated -atings of 24 tons. The new suspension is available only on the tandem-drive (6 x 4) tersions, but existing four-spring 6 x 2 and 5 x 4 versions of these three models remain n production. Compared with the bur-spring types, the new twin-spring bogie tdds about 120kg (2651b) to the unladen ;hassis weight.

Also announced today is the increased ivailability of the High Ground Clearance )ackage option, which has been available in the 22and 24-ton models since their ntroduction. The availability of this option s being extended to the new twin-spring nodels and to all D Series trucks, tippers nd tandems from the D1210 model tpwards.

When the DT22I4. DT2417 and )T2418 models were introduced in 1969, hey were available only with four-spring uspension, the two springs on each side iing in the same plane and being connected at their inner ends by a rocking beam to equalize the loading on each axle. This suspension is of the "non-reactive" type with an interconnecting linkage consisting of bell cranks and compression rods joining the rear ends of each spring on each side. This reduces axle lift (or "hop") due to driving and braking torque reactions, as occurs with a conventional four-spring bogie without this interlinkage.

This original bogie type proved ideal for normal on-off road usage, but the vertical axle movement tended to be too restricted for satisfactory operation over very rough ground.

The new two-spring system allows a high degree of inter-axle vertical movement permitted by the spring mounting arrangements and means that there can be a height difference of 280.0mm (11.0in.) between the wheels on each side without affecting the chassis frame height. This means, says Ford, that the leading driving wheel on one side can be in a dip 140.0mm (5.5in.) deep and the rear wheel on the same side on a bump of the same dimension while the chassis remains on an even keel.

An air-operated inter-axle differential lock is fitted to the DT1711 DT2014 6 x 4 models, and this feature is now standard in the new twin-spring chassis. Even if one rear wheel should be lifted clear off the ground when travelling cross-country, the driver can keep going by use of the third-diff lock. With the high articulation afforded by the new twin-spring bogie, the chances of one wheel lifting off the surface are remote, so the limiting factor for traction will mainly be that of tyre pattern and condition.

Like the Ford interlinked four-spring layout, the new suspension has completely non-reactive characteristics, so there is no