DODGE 5C

Page 90

Page 91

Page 92

Page 93

Page 94

Page 99

Page 100

If you've noticed an error in this article please click here to report it so we can fix it.

SERIES By A P.

E M.IRTE

A A new range of tilt-cab V8-engined chassis up b

.t.w.

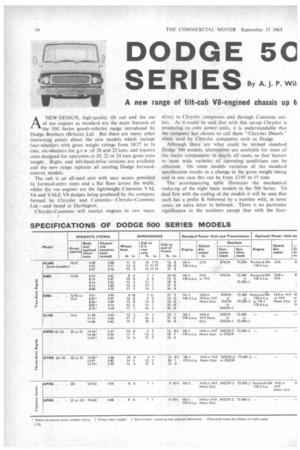

ANEW-DESIGN, high-quality tilt cab and the use of vee engines as standard are the main features of the 500 Series goods-vehicles range introduced by Dodge Brothers (Britain) Ltd. But there are many other interesting points about the new models which include four-wheelers with gross weight ratings from 10.27 to 16 ions. six-wheelers for g.v.w. of 20 and 22 tons, and tractive units designed for operation at 20, 22 or 24 tons gross train weight. Rightand left-hand-drive versions are available and the new .range replaces all existing Dodge forwardcontrol models.

The cab is an all-steel unit with easy access provided by forward-entry steps and a flat floor across the width, whilst the vee engines are the lightweight Cummins VAL V6 and VALE V8 designs being produced by the company formed by Chrysler and Cummins—Chrysler-Cummins Ltd.—and based at Darlington.

Chrysler-Cummins will market engines in two ways;

direct to Chrysler companies and through Cummins outlets. As it -could be said that with this set-up Chrysler is producing its own power units, it is understandable that the company has chosen to call them "Chrysler Diesels" when used by Chrysler companies such as Dodge.

Although there are what could be termed standard Dodge 500 models, alternatives are available for most of the major components in nearly all cases, so that layouts to meet wide varieties of operating conditions can be obtained. On some models variation of the standard specification results in a change in the gross weight rating and in one case this can be from 12-95 to 15 tons.

The accompanying table illustrates the mechanical make-up of the eight basic models in the 500 Series. To -deal first with the coding of the models it will, be seen that each has a prefix K followed by, a number with, in some cases, an extra letter in between. There is no particular significance in the numbers except that with the four eelers it gives an dication of proximate body d payload allowe, so that, for tmple, • the K800 carry about 8 tons whilst the K1100 can have a body

d payload of about 11 tons. The additional letters have rious meanings—the L in the KL600 indicates that this designed to give a low platform height, a P is included the tractive unit model code, whilst the six-wheelers ye an R when there is a single-drive rear bogie and a when the model is a 6 x 4.

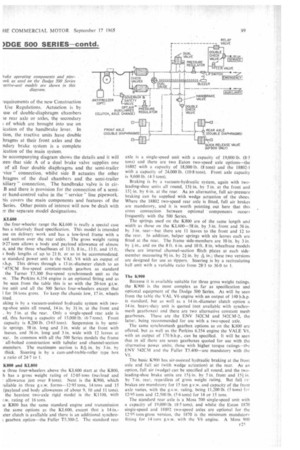

e Tilt Cab There is not a lot of similarity between the various 500 ries models, but the new forward-control cab is used thout exception. There is only one version and this is a very well made all-steel unit, well fitted and finished internally to afford a high degree of driver comfort. As already pointed out the cab tilts forward—it is hinged at the forward end—for access to the engine. Daily tasks such as oil and water checks can be carried out easily with the cab down.

Access to the cab for the driver and passengers is by steps forward of the front wheels. The cab extends well forward of the front axle, front overhang being 4 ft. 71 in. except on the KL600, where it is 4ft. 61 in., whilst distance from the bumper to the back of the cab is 5 ft. 61 in., meaning that the cab extends 11 in. or 12 in. behind the front axle centreline.

The tilt is torsion-bar controlled, this being located at the front pivots, and there are substantial mounting brackets which are bolted to the main longitudinals of the cab substructure. The torsion bar goes through a transverse tube joining the cab brackets, being fixed to the tube at the left-hand side, whilst at the right-hand side it is splined to a drop arm. The bottom fixing of the drop arm can be adjusted to vary the torsion loading and therefore the effort required to tilt the cab.

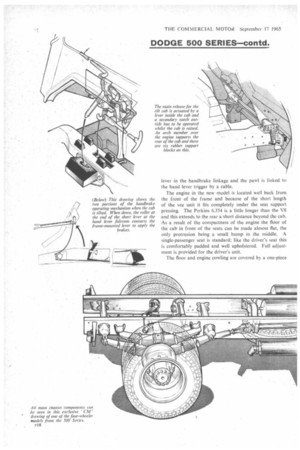

At the rear, the cab is supported (when down) on an arch member which goes over the engine through four rubber blocks at the top and one at each side. There is spigot location and the cab is locked on to the member by a double-catch mechanism. The main release is by a lever in the cab and there is a safety catch operated from the outside.

Tilting the cab requires no dismantling of parts. Steering is through a double-universally-jointed column which accommodates movement of the wheel relative to the box: the clutch is hydraulically operated and the actuating cylinder is mounted on the cab, as is the brake-operating gear, and the gear-change lever is positioned so that it passes through a hole in the cab bottom pressing.

For the other item that can cause a problem on tilt-cab design—the handbrake—there is an interesting solution. The operating mechanism is in two parts, one fixed to the cab, the other to the chassis frame. The cab portion consists of the hand lever and pivot, whilst on the frame there is a short lever connected to the mechanical linkage to the rear brakes. Where the handbrake is power assisted there is a second lever linked to an air valve.

The connection between the two parts of the handbrake mechanism is made through a roller on a short right-handle extension to the hand lever; as the lever is pulled this applies pressure to the frame-mounted lever. The handbrake is held on by a ratchet and pawl at the first relay lever in the handbrake linkage and the pawl is linked to the hand lever trigger by a cable.

The engine in the new model is located well back from the front of the frame and because of the short length of the vee unit it fits completely under the seat support pressing. The Perkins 6.354 is a little longer than the V8 and this extends to the rear a short distance beyond the cab. As a result of the compactness of the engine the floor of the cab in front of the seats can be made almost flat, the only protrusion being a small hump in the middle. A single-passenger seat is standard; like the driver's seat this is comfortably padded and well upholstered. Full adjustment is provided for the driver's unit.

The floor and engine cowling are covered by a one-piece ibber moulding which is lined with fibre to provide )und insulation. The brake and clutch pedals are pendant iounted so there are no apertures to cause draughts and general the cab sealing is very good. The interior is illy lined and standard fittings include a central ashtray, a aat hook and a courtesy light. There is a good-sized abby-hole on the left-hand side of the dash and options vailable include fresh-air heating and demisting equiplent, a suspension-type driver's seat and a two-man assenger seat.

All-round visibility is excellent; there is a good-sized indsereen, whilst at the rear there are only narrow pillars etween the large window and glazed corner lights. iinding windows are fitted in the doors with large quarter ghts which swivel open for ventilation. About 77 per :nt of the 34 sq. ft. windscreen is cleared by the electrically riven twin wipers, which carry 20 in. blades on 17n. arms ad are asymmetrically placed to the driver's side.

Iechanical Units To deal with the main mechanical units.used in the new odge range there are three basic power units—the V6. 8 and Perkins 6.354—but because there are two powerutput versions of the V6, ur engine types are used. he vees will be fairly well aown because of the publicity ley received at the time of le last Commercial Show. he V6 has a bore and stroke

4.625 in. and 3,5 in. re:ctively to make the cubic

,pacity 352 cu. in. (5.77 :res). The difference between the two versions of the V6 unit used by Dodge is only in respect of power output and maximum speed; the V6-1 gives a maximum of 130 b.h.p. gross at 3,000 r.p.m., whilst the V6-2 gives 140 b.h.p. gross at 3,300 r.p.m. The maximum gross torque of both versions is 248 lb. ft.—at 1,800 r.p.m. for the V6-1 and at 1,900 r.p.m. for the V6-2. The V8 has the same bore and stroke dimensions as the V6, which give a capacity of 470 cu. in. (7-7 litres); the maximum gross output is 170 b.h.p. at 3,000 r.p.m, and maximum gross torque at 1,800 r.p.m.

The engines have some special features as used by Dodge, such as the use of an alternator mounted at the rear of the engine located in the vee and belt-driven by a pulley at the end of the drive train for the fuel pump and compressor, The pulley is provided with mounting holes for a power take-off point.

The Perkins 6.354 is a very well known unit and the version used by Dodge gives a maximum gross output of 120 b.h.p. at 2,800 r.p.m. and a maximum gross torque of 260 Ib. ft. at 1,750 r.p.m. Although the Perkins engine is a little longer than the vee and protrudes farther to the rear, this does not have'any effect on the body space available. The distance from the centreline of the front axle to the rear cab panel is 11 in., but 7 in. 'extra has to be allowed between the cab and the body fitted to give space for maintenance of the gear-change linkage and alternator drive, and this caters amply for the extra length of the Perkins 6.354.

It will be seen from the chart that on each •model a live-speed constant-mesh gearbox is standard, with a five.-peed synchromesh optional. In most eases there are alternatives of. each type available and seven „gearboxes in all are used—three ENV, constant-mesh units arid four Fuller synchromesh designs. This number is made uP by there being two basic ,boxes in each classification having different input torque -ratings; three of the units have alternative sets of ratios to make them more suitable for use with two-speed rear axles and all have direct-drive top ratios. • • •

The ENV boxes are the 475 CM, the 542CM and the 542 CM-2. The 475CM has a torque capacity of 275 lb. ft. and ratios of 6-92, 3.78, 2-24, 1.47 and I to 1 forward and 6.86 to I reverse. Ratios of the.542 CM are 7-67, 4-31, 2.51, 1-48 and 1 to 1 forward and 7-48 to 1 reverse, whilst the 542CM-2 unit has forward ratios of 7.0, 3-92, 2.15, 1.19 and 1 to 1 and 6,82 to I reverse. Torque capacity of the basic box is 325 lb. ft., but because of the higher bottom ratio this figure is increased to 375 lb. ft. for the 542 CM-2.

Whilst only one of the ENV boxes is available with an alternative set of ratios—these are recommended for use with two-speed axles where they provide 10 distinct forward ratios—both basic Fuller synchromesh units can be had with optional ratios. The T5.300 has ratios of 7.58, 4.38, 2.40, 1.48 and 1 to 1 forward and 7.20 to I reverse, whilst the T5.300-2 has forward ratios of 7.58, 4-10, 2.13. 1-17 and I to 1 and the same value reverse; torque capacity is the same for both (because the bottom ratios are identical) being 2801b. ft.

There is an increase to 400 lb. ft in torque capacity for both T5.400 boxes and whilst the basic unit has forward r-?0 ratios of 7.36, 4-73. 2.79, 1-66 and 1 to 1 with 7.36 to 1 reverse, the T5.400-2 has forward ratios of 7-36, 3-86, 2-15. 1-19 and I to 1 with reverse also 7-36 to 1. The actual gearbox which can be specified for a particular model depends primarily on the engine fitted.

Single-speed rear axles are standard on the four-wheel rigids with two-speed units optional on all except one model, but on the tractive unit and six-wheelers only two. speed are available. The single-speed units are from a variety of manufacturers, including Moss and Eaton, but all the two-speed axles are Eaton.

All the axles have spiral-bevel final drive and a complicated list of the ratios recommended has been compiled by Dodge for all the chassis models with their various specification possibilities and for different types of operation. The ratios that are available for the single-speed axles are as follows: Type 500-5-86 and 5-12 to I; Type 700-6-83 and 6.1%; Type 900-6-16 and 6-66; Type 1000--6-66; Eaton 1870-7-17.

The Eaton 16802-11 two-speed axle is used with four alternative sets of ratio-5-57/7.75, 6-14/8.54, 6-50/9-04 and 7.17/9.77 to 1. The two versions of the 18802 axle are used by Dodge, the ratios available with the 18802 Mk. 1 (wide track) being 5.57/7.60, 6-50/8-87 and 7-17/9.77 to I, whilst the Mk. H (narrow" track) version can have only the last two.

These two-speed axles cover all the four-wheelers—rigids and tractive units. On the.six-wheelers, the 18802 Mk. 1 is used on the 6 X 2 with either 6.50/8-87 or 7.17/9-77 ratios. In the case of the 6 x 4 model with the 30 DT bogie, 16000 Series axles are employed, whilst the 38 DT has 18000 Series axles. In both Cases ratios of 7.17/9.77 are offered with the alternative for the 30 DT, 650/9.02 to 1

. and for the 38 DT, 6-50/8.87 to I. • .

As will be seen from the table, air-pressure brakes are either standard or optional on all of the 500 Series models except the KL600, and with the full-air system, front and. rear brakes are on independent circuits. Vacuum equipment is by Clayton Dewandre, whilst hydraulic components including brake units—are of Lockheed manufacture. On .air-presiure systems, all valve and brake chamber's are Westinghouse, whilst wedge-operated brake units ale Lockheed and cam brakes are Girling.

The 16-ton-gross four-wheelers, the six-wheelers and tractive unit have air-pressure-assisted handbrakes to meet

-equirements of the new Construction Use Regulations. Actuation is by use of double-diaphragm chambers le rear axle or axles, the secondary ; of which are brought into use on ication of the handbrake lever. In tion, the tractive units have double hragms at their front axles and the ndary brake system is a complete ication of the main system.

ie accompanying diagram shows the details and it will men that side A of a dual brake valve supplies one of all four double diaphragms and the semi-trailer -vice " connection, whilst side B actuates the other hragms of the dual chambers and the semi-trailer xiliary " connection. The handbrake valve is in cirB and there is provision for the connection of a semier hand-control valve in the " service " line pipework. is covers the main components and features of the Series. Other points of interest will now be dealt with

the-separate model designations.

KL600

the four-wheeler range the KL600 is really a special case has a relatively fixed specification, This model is intended use on delivery work and has a low-level frame with a Led section over the rear axles. The gross weight rating 3-27 tons allows a body and payload allowance of almost is, and the three wheelbases of lift. 8 in., 13 ft. and 15 ft. if body lengths of up to 21 ft. or so to be accommodated. le standard power unit is the VAL V6 with an output of ).h.p. This drives through a 13 in.-diameter clutch to an '475CM five-speed constant-mesh gearbox as standard the Turner T5.300 five-speed synchromesh unit as the in. The Perkins 6.354 engine is an optional fitting and as be seen from the table this is so with the 20-ton g.t.w. lye unit and all the 500 Series four-wheelers except that I for 16 tons gross.. To keep the chassis low, 17 in. wheels itted.

aking is by a vacuum-assisted hydraulic system with twang-shoe units all round, 14 in. by 31 in. at the front and . by 5 in. at the rear. Only a single-speed rear axle is ed, this having a capacity of 15,000 'b. (6.7 tons). Front capacity is 8,200 lb. (3.65 tons). Suspension is by semi:ic springs 58 in. long and 3 in, wide at the front with leaves, and 56 in. long and 3 in. wide with 12 leaves at ear. In common with all the 500 Series models the frame all-bolted construction with tubular and channel-section members. The maximum section is 8-& in. by 3 in. by thick. Steering is by a earn-and-treble-roller type box a ratio of 24-7 to 1.

K800 and KI,800 le three four-wheelers above the KL600 start at the K800, h has a gross weight rating of 12-05 tons (payload and

• allowance just over 8 tons). Next is the K900, which milable in three g.v.w. forms-12.95 tons, 14 tons and 15 (payload and body allowances of about 9, 10 and 11 tons). the heaviest two-axle rigid model is the K1100. with r.w. rating of 16 tons.

le K800 has the same standard engine and transmission the same options as the KL600, except that a 14 in.eter clutch is available and there is an additional synchro. I gearbox option—the Fuller T5.300-2. The standard rear axle is a single-speed unit with a capacity of 19,000 lb. (8-5 tons) and there are two Eaton two-speed axle options—the 16802 with a capacity of 18,000 lb. (8 tons) and the 18802-1 with a capacity of 24,000 lb, (10.8 tons). Front axle capacity is 9,600 lb. (4.3 tons).

Braking is by a vacuum-hydraulic system, again with twoleading-shoe units all round, 1.5.1 in. by 5 in, at the front and 151 in. by 6 in. at the rear. As an alternative, full air-pressure braking can be supplied with wedge actuation of the shoes. Where the 18802 two-speed rear axle is fitted, full air brakes are mandatory. and it is worth pointing out here that this cross connection between optional components occurs frequently with the 500 Series, The springs used on the 1(800 are of the same length and width as those on the KL600-58 in. by 3 in. front and 56 in. by 3 in. rear—but there are 11 leaves to the front and 12 to the rear. In addition, helper springs with six leaves each artfitted at the rear_ The frame side-members are 10 in. by 3 in. by in.. and on the 8 ft. 6 in. and IO ft. 8 in, wheelbase models there are internal channel-section flitch plates at each sidemember measuring 91 in. by 2-1 in. by .12, in.; these two versions are designed for use as tippers. Steering is by a recirculating ball unit with a variable ratio from 28-3 to 36-0 to 1.

The Ii900

• Because it is available suitable for three gross weight ratings. the 1(900 is the most complex as far as specification and optional equipment of the Dodge 500 Series. As will be seen from the table the VAT. V6 engine with an output of 140 h.h.p. is standard, hut as well as a 14 in.-diameter clutch option a 14 in. heav} -duty unit is quoted (not available with synchromesh gearboxes) and there are two alternative constant mesh gearboxes. These are the ENV 542CM and 542CM-2, the latter, being recommended for use with a two-speed axle.

The same synchromesh gearbox options as on the K800 are offered, but as well as the Perkins 6.354 engine the VALE V8, with an output of 170 b.h.p., can be specified. It will be seen that in all there are seven gearboxes quoted for use with the alternative power units: those with higher torque ratings—the ENV 542CM and the Fuller T5.400—are mandatory with the V8.

The basic 1(900 has air-assisted hydraulic braking at the front axle and full air (with wedge actuation) at the rear. As an option, full air (wedge) can be specified all round, and the twoleading-shoe brake units are 151 in. by Sin, front and 15+ in. by 7 in, rear, regardless of gross weight rating. But full rtr brakes are mandatory for 15 ton g.v.w. and capacity of the front axle varies, with the g.v.w. rating. being 11.200 lb. (5 tons) kr 12.95 tons and 12,500 lb. (5.6 tons) for 14 or 15 tons.

The standard rear axle is a Moss 700 single-speed unit with a capacity of 19,000 lb. (8.5 tons). and whilst the Eaton 1870 single-speed and 18802 two-speed axles are optional for the 12-95 tons gross version, the 1870 is the minimum mandatory fitting for 14 tons Et:rim. with the V6 engine. A Moss 900 r25

single-speed (21,5001,b.) axle is the minimum with the V8 or Perkins unit at this weight and the 18802 must be specified for 15 tons g.v.w. with the V6; the 1870 can be used with the V8. Both the 1870 and 18802 axles have a rating of 24,000 lb. (10-8 tons).

It is also natural that the suspension should vary between the three gross weight versions, but this is only in respect of spring capacity. The dimensions do not change, being 58 in. by 31 in. at the front and 56 in. by 34 in. at the rear, In both cases the springs have 10 leaves and at the rear there are sevenleaf helper springs. Dimensions of the chassis side-members are 12 in. by 3 in. by + in. and steering is by a recirculating ball unit with variable ratio from 30-8 to 46-0 to I.

Both the K800 and K900 are available in five wheelbase dimensions, the two shortest in each case being intended for tipper applications, and the three longer versions for general haulage. with the longest allowing a body length of around 24 ft, Only these last four can be rated for 15 tons gross as the minimum wheelbase for this undef the latest Construction and Use Regulations is 10 ft. 8 in. and, of course, the chassis has to be plated to be operated at this weight.

The K1100 Also because of the wheelbase requirement for running at the new gross weight limit. the 16-ton-gross machine K1100 has a limited wheelbase range, the three versions available being 12 ft. 3 in., 17 ft. 2 in. and 19 ft. 1 in. wheelbase. The last provides for a body length of 25 ft. The VALE V8 engine is the only one that can be specified and the gearbox options include types recommended for use with two-speed axles. The standard single-speed rear axle is an Eaton 1870 and the option a Moss with the same capacity of 24.000 lb. (10-8 tons), whilst the alternative two-speed unit is an Eaton 18802.

Braking is by a full-air system with cam-actuated leadingand-trailing shoe units at all wheels-151 in. by 6 in. front and 151 in. by 8 in. rear. Separate air circuits are used for the front and rear service brakes and dual-diaphragm brake chambers are fitted at the rear axle. The secondary side of these is pressurized on application of the handbrake by a valve in the linkage to meet the requirements of an adequate and separate secondary-brake system.

The steering unit is the same as that on the K900 and the springs have the same dimensions, but the fronts have 13 leaves and the rears 12 main leaves and seven-leaf helper springs Front axle capacity is 14,000 lb. (6.25 tons) and the frame sidemembers measure 12-k in, by 3-in. by lor, in. thick.

Tractive Units There is an interesting complication in the tractive unit models as the two basic designs—the KP700 and KP900—are offered for 20 and 24 tons g.t.w. respectively and do not need to be plated in these forms. But the KP900 is available rated for 22 tons g.t.w., at which weight it could be used with a single-axle semi-trailer within the latest C. and U. Regulations. and it must then be plated.

Whilst the KP700 has power-unit and transmission options similar to those available on the K900, only two-speed axles can be specified. The KP900 is based on the KI100 and, like that model has a VALE V8 170 b.h.p. engine without option. As

again only a Iwo-speed axle is available, the special versions of the ENV 542CM constant-mesh and Fuller T5.400 synchromesh gearboxes are specified.

Both tractive units have full-air, dual-circuit brake systems. but there is a difference in the wheel brakes, The KP700 has wedge-actuated two-leading-shoe units and the KP900 camactuated leading-and-trailing-shoe units. A power-assisted handbrake is used on the two models and the brake drums have the same diameter of 151 in. all round, but the fronts have 5 in.-wide linings on the KP700 and 6 in.-wide on the KP900. The rears are 7 in. wide in both eases.

Front-axle capacity goes up from 9,600 lb. (4.3 tons) on the KP700 to 11.200 lb. (4-95 tons) on the KP900 and the suspension also has a higher capacity for the heavier-weight model. The spring lengths are the same-58 in. front. 56 in. rear—but the KP900 has 31 in. springs against 3 in. and 10-leaf helpers at the rear springs against six-leaf.

Maximum frame section on the KP700 is 10 in. by 3 in. by

in. and the depth is increased to 12 in. for the KP900. Steering is by a recirculating ball unit on both models with the ratio (variable) from 28-3 to 36.0 to 1 on the KP700 and 30-8 to 46-0 to I on the KP900.

The Six-wheelers The two six-wheelers differ only in respect of the rear bogie. The KR900 6 X 2 has York trailing-arm suspension for the trailing axle with the driving axle carrying a pair of leaf springs. whilst the KP900 6 X 4 has an Eaton-Hendrickson steel-sprung bogie. The alternatives (both have two-speed drive) can be seen in the table.

As with the K1100 four-wheeler and KP900 tractive unit. only the V8 engine is available. The ENV 542CM is an optional constant-mesh gearbox recommended when improved gradient-climbing ability is desirable.

The basic six-wheelers are rated for 20 tons gross and only the longest-wheelbase versions are suitable for plating for 22 tons g.t.w. This is because the outer-axle dimension for 22 tons has to be at least 18 ft. When the increased weight rating is provided. 11.00-20 (16-ply) front tyres and 9.00-20 (14-ply) rears arc mandatory. Front-axle capacity of both models is 14,000 lb. (6.25 tons) and the braking system is full-air with cam-actuated leading-and-trailing-shoe units all round and an air-assisted handbrake.

There are separate circuits for front and rear brakes and at the rear there are dual diaphragms, with the secondary diaphragm for the handbrake. Single-diaphragm chambers arc used at the front axle, Brake sizes are 15+ in. by 6 in. front and 151 in. by 7 in. rear, and the same size frame (12k in. by 3 in. by f, in.) and the same ratio steering (from 30.8 to 46-0 to 1) is also used on both models.

Although the standard specification of the new Dodge range is relatively full, a wide variety of optional equipment, apart from major components already referred to, is available. This depends on the model, as what is optional for one model can be standard on another. The list includes a high-capacity heater and demister unit, frontand rear-spring dampers, windscreen washer, a dual passenger seat, heavy-duty springs. power-assisted steering, power take-off equipment, extra cab insulation and smaller items, such as sun vizors, safety belts and a steering-column locking device.

Prices for the various models and options have been issued by Dodge. Examples are shown below.