HIGI• and MIGHT)

Page 84

Page 85

Page 86

Page 89

If you've noticed an error in this article please click here to report it so we can fix it.

Oft. tall and having 225 b.h.p.,

vorth tractive unit used by By R. D.

rrailer Co. demonstrates the AMInst BE

fity of 32 tons on four axles

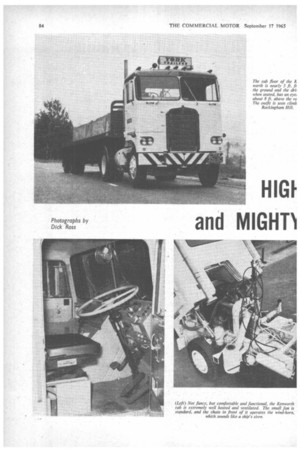

.cab takes 30 see. to tilt and is .done most of the routine its are easy to get at. The e the air-cleaner operates the hanism: a small tyre innersed • to seal the air-cleaner tint. The exhaust pipe tonspherical, the bail-end of the dpe being held tij) into the pipe by a two-leaf spring.

most people first confronted with a widespread axle

my first thoughts were for the wear and tear on tyres. This must of necessity be greater than that experienced on conventional tandem-axled designs but, surprisingly, is not so great as one might expect, except when the outfit is being turned short. But it was very noticeable that when I expected the scrub to be felt there was little evidence that it was any worse than that experienced with close-coupled designs.

I refer to times during the test when it was necessary to pull out of side turnings and make. right-angle turns into a main road. Such a

rnanceuvre usually has to be hurried because of traffic 'approaching fast from both directions, and the amount of drag created by a heavily laden tandem bogie being dragged sideways is nearly always noticeable.

At these times the widespread unit is no worse than the others, but it is not the machine that a sensible operator would put to work where there was a lot of tight turning to do. The attendant increase in payload of nearly 2 tons, however, even with the Kenworth (which weighed 5 tons 11 cwt. 2 qtr.) is a factor that cannot be ignored, and it may well be that one could afford lower tyre mileage.

The impression I gained from the general handling of the outfit was that when travelling fast in a straight line the tendency of the rear bogie to follow a straight course gave it an edge with regard to stability. Conversely, I felt that problems might arise when negotiating a twistY, slippery road, especially should the trailer be part-loaded and, as so often happens. heavy on the back end.

There is nothing fancy about the Kenworth. Everything that is fitted is purely functional. although some of the marker lights that are carried are of no use in the UK. It is powered by a Cummins NH 250, six-cylinder diesel engine, derated to 225 b.h.p. at 2,100 r.p.m., driving through a 14 in. twin-plate clutch and a 10-specd, twin-countershaft gearbox having extremely close ratios, thence through a single-piece propeller shaft to a single-speed, spiral-bevel, fully-floating rear axle.

The gearbox ratios are 8.05; 6.30; 4.99; 3.95; 3.20; 2.51; 1-97; 1-56; 1.24 and 1 to I. Two ratios are obtained in reverse, these being 2.73 and 8.73 to 1. The axle-ratio at the time of the test was 6.166 to 1. but because the top speed was on the low side— about 42 m.p.h.—York engineers intend to alter this to 4.625 to 1, when top speed will be about 50 m.p.h.

The gear ratios are obtained through a five-speed main train and an air-operated two-speed splitter unit. The system of obtaining the correct sequence is that of engaging low-ratio in the splitter and changing from first to fifth gears. Whilst still on power in fifth, the air-shift lever is moved to the high-ratio position. When the speed of the vehicle is sufficient to allow another change to be made this is done in the normal manner and, as soon as the power is removed from the transmission, the air unit will at the same time move the splitter gears to the high-ratio position. I found it advantageous to miss out sixth gear, going direct from fifth to seventh. This was purely to make the actual changing easier, the position of the first and sixth gear requiring the overcoming of a spring-loaded gate.

Loaded as it was to 31 tons 10 cwt., the vehicle's acceleration times were, through the gears, 0 to 20 in 21.5 sec.; 0 to 30 in 39.8 sec.; and 0 to 40 in 816 sec, In direct drive the times from 10 m.p.h. to 20, 10 to 30 and 10 to 40 were 26 sec., 51.7 sec. and 99.1 sec. respectively.

It was noticeable when making these tests that the first five gears allowed acceleration to be made as fast as the engine would rev up to its peak, It was not until reaching seventh ratio that there was any need to hold on to the gear longer.

The hill climb was carried out on Rockingham Hill on A6003 in an ambient temperature of 25°C (77°F). This hill has an average gradient of / in 12, a steepest gradient of I 2

1 in 6 and is 0.6 miles long. The total time taken to climb to the top was 3 min. 45-4 sec. and the lowest gear used was third. engaged for 1 min. 43 see., when the lowest speed recorded was 7 m.p.h. When checked at the bottom of the hill the engine coolant temperature was 71°C (160°F). At the top this had risen to 78°C• (174°F).

Turning round and facing down the hill the outfit was allowed to coast to the bottom at 20 m.p.h., being held by the brakes to that speed. A maximum-pressure stop at the bottom produced a Tapley meter reading of 45 per cent.

A second climb was made during which stop-and-start tests were made and the various braking systems were checked for holding ability. Starts in second gear were reasonably easy whilst facing up hill, but the handbrake on the tracthe unit would not hold oh the steepest section. . Facing down the hill a start was made in low-reverse with complete ease. but again the handbrake would not hold. On both the upand downfacing tests of the handbrake, the other two emergency system; held the outfit with plenty in hand.

At this point I should explain that there is no handbrake as such fitted on the Kenworth, the unit serving this purpose being a pair of spring-brakes mounted on the driving axle of the tractive unit controlled by a valve operated by striking a knob, in addition, there are spring brakes on the semi-trailer operated in the same manner and a third-line system, operating the semi-trailer brakes and the front axle brakes of the tractive unit through a hand-reactor valve.

One further control apart from the conventional footbrake which of course operates on all wheels—is a line-pressure reducing valve intended to limit the braking efficiency for use on slippery conditions.

Results obtained from brake tests carried out on the footbrake were: from 20 m.p.h., 33-3 ft., showing 55 per cent on the Tapley meter and from 30 m.p.h., 70k, showing 60 per cent on the meter. The average retardation for these tests was 12.5 ftisec.2 and 14.9 ft/see.2 respectively. It will be seen that the fade recorded at 20 m.p.h. proved to be 10 per cent, which is very good for four axles at this weight.

Tests on the alternative braking systems produced the following figures; Tractive-unit handbrake, from 20m.p.h., 7 per cent Tapley; semi-trailer brakes only, from 20 m.p.h., 30 per cent Tapley; emergency third-line, from 20 m.p.h., 32 per cent, and from 30 m.p.h., 36 per cent. On all the stops made there was a complete absence of any feeling that the vehicle would get out of hand, but the semi-trailer brakes—both on the maximum pressure stops and the trailer-brakes-only stops— locked completely, leaving a considerable amount of rubber on the road.

This was not a full test of the outfit, but approximate m.p.g. figures were obtained. On a stretch of A427 from Corby to Willbarston and return, a total distance of 10 miles over what can only be described as a poor road for a vehicle of this nature. fully laden the unit returned 5 m.p.g. Towing a Freightmaster boxvan unladen, the figure was 8 m.p.g. The average speeds made were 18-8 and 24-75 m.p.h. respectively. There is little doubt that these figures would have been considerably better I the road conditions been more in keeping with the vehicle. /river comfort in this machine is first-class by any standards ! the driver is insulated from the majority of road shocks ! chassis vibrations by the Bostrom Viking suspension seat. ibility is excellent from the exceptionally high seating posit, marred only by a blind spot created by the Western-type 01 the controls of the machine are well placed and the usion of items such as a cigar lighter and an electric fan cab void of fancy leather trim and chromium plate, shows t there is more to making a cab comfortable than just making wetty. The position of the exhaust at the rear of the cab kes it somewhat noisy when the machine is on full power I I had a ringing in my ears at the end of the test.

fairly high front axle loading made the steering on the icle somewhat too heavy for my liking. I felt that power :ring would have been a distinct advantage, despite the fact t the ratio of the box is 28-4 to 1 and that the wheel is 22 in. Jiameter Air-operated wipers clear a large area of screen I the use of fiat glass in the screens avoids the need for fancy I expensive blades.

'rom the engineers point of view the Kenworth is first

class, being fitted with a tilt cab that really tilts. Considerable thought has gone into the location of the various auxiliaries so as to make them accessible. The operation of the tilting mechanism of the cab is hydraulic and it takes exactly 30 sec. to clear, unlatch and tilt it complete with all the controls. except the gear lever. Mounted on the back of the cab, the exhaust and air cleaner systems also tilt away from where they are not wanted when work is being done.

Throughout the test I noticed that the outfit was extremely taut when being put round corners fairly fast and it was not until the spare unladen trailer was coupled that I noticed the substantial anti-roll bar that was included in the rear suspension of the tractor. To enable the accommodation of a number of different sizes of semi-trailer the Kenworth is equipped with the York sliding fifth-wheel, giving kingpin positions from 20 to 32 in. forward of the driving axle.

Construction of the semi-trailer was of the standard pattern used in the Teamster range, with castellated l-section main frames, diamond-section tubular cross-members and pressed steel cross-bearers. Axles of 22,500 lb. capacity fitted with 15-5 by 7 in. S cam brakes and 9.00-20 14-ply tyres were fitted. The landing gear was the York inverted screw, oil-bath type, whilst the deck was of lin. nominal thickness hardwood. A 3 ft.-high corrugateo-steel headboard was substantially braced forward on to extensions of the main frame, providing a high degree of safety in the event of a collision causing the load to shoot.