ANEW COVENTRY CLIMAX Sixcylindered Engine

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Particulars of a Fine Power Unit Suitable for Use Both in Passenger and ,Goods Vehicles.

A NY engine produced nowadays for use in a t 'commercial type of vehicle must be able to withstand prolonged hard work without the risk of failure of any component. It stands to reason, therefore, that the design of such a power unit has to provide for all sorts of contingencies, but first and foremost the construction must be of a robust nature and all bearings of such dimensions that they are only comparatively lightly loaded. The sponsors of the new Coventry Climax six-cylindered engine must clearly have realized this, for the whole unit is built in a manner that suggests that it is "made to last," whilst a great deal of care has obviously been expended on the consideration of details—a most important point in any internal-combustion engine.

An Outstanding Feature of Design.

The most noticeable feature of the design is that the engine is built up almost entirely of cast-iron, in order to provide great rigidity. The sump, which, of course, carries very little load, is an aluminium casting, but the crankcase is formed in a close-grained grey iron, and is of such shape as to give great strength, which, in turn, enables it to form a particularly rigid mounting for the four-bearing crankshaft. In passing it may be mentioned that each of the bearings is formed in webs which run right across the interior of the case, and they are all of a thoroughly substantial nature. Extra transverse strength is provided by additional webs in which the journals for the camshaft are formed, and as the whole structure is well braced at each end it should be possible for the engine to run at high rates of revolution speeds without vibration.

Before going further it • would be advisable to give the exact bore and stroke dimensions. These are 3i ins. and 5 ins, respectively, giving a total piston displacement of 353.8 cubic ins.; the R.X.C. rating is 36 h.p.

The cylinders are formed in a monobloc casting, which is sufficiently deep to give added strength to the crankcase when it is bolted toit. Side-by-side valves are employed, and these are, of course, carried in the

B22 cylinder casting in much the normal manner. In order to facilitate decarbonizing and the work involved in overhauling, the cylinder head is detachable, and, what is more to the point, is clear of any obstructions, so that it can be lifted quickly and easily.

We have already said that the crankshaft is carried in four main journals. This particular unit, however, is a very robust affair, counterbalanced throughout its whole length and dynamically balanced on a Gishoit balancing machine. Steel connecting-rods of rather special design are included in the specification, likewise Invar-strut-type aluminium pistons. We shall refer to the connecting-rods again later.

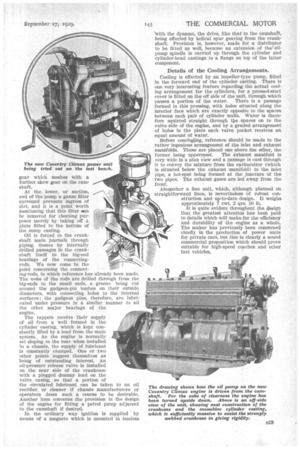

As might be expected in an engine such as this new Coventry Climax, the lubrication system has come in for its full meed of attention. In the first place we will describe the oil-pump drive in detail, for it is of more than passing interest. As will be seen from one of the drawings, the pump body itself is attached tl the can of one of the intermediate crankshaft bearings. The driving spindle actually passes through the mainbearing block itself and at its upper end has a skew gear which meshes with a further skew gear on the camshaft.

At the lower, or suction, end of the pump a gauze filter surround prevents ingress of dirt, and it is a point worth mentioning that this filter an

• be removed for -cleaning purposes merely by taking off a plate fitted to the bottom of the sump casting.

Oil is forced to the crankshaft main journals through piping, thence by internally drilled passages in the crankshaft itself to the big-end bearings of the connectingrods. We now come to the point concerning the connecting-rods, to which reference has already been made. The webs of the rods are drilled through from the big-ends to the small ends, a groove being cut around the gudgeon-pin bushes on their outside, diameters, with connecting holes to the internal surfaces; the gudgeon pins, therefore, are lubricated under pressure in a similar manner to all the other major bearings of the engine.

The tappets receive their supply .

of oil from a well formed in the cylinder casting, which is kept con stantly filled by a lead from the main system. As the engine is normally set sloping to the rear when installed in a chassis, the supply of lubricant is constantly changed. One or two other points suggest themselves as 'being of outstanding interest. An oil-pressure release valve is installed on the near side of the crankcase with a plugged dummy lead on the valve casing, so that a portion of the circulated lubricant can be taken to an oil rectifier or cleaner if chassis manufacturers or operators deem such a course to be desirable. Another item concerns the provision in the design of the engine for fitting a petrol pump adjacent to the camshaft if desired.

In the ordinary way ignition is supplied by means of a magneto which is mounted in tandem

'with the dynamo, the drive, like that to the camshaft, being effected by helical spur gearing from the crankshaft. Provision is, however, made for a distributor to be fitted as well, because an extension of Mei oilpump spindle is carried up through the cylinder and cylinder-head castings to a flange on top of the latter component.

Details of the Cooling Arrangements.

Cooling is effected by an impeller-type pump, fitted in the forward end of the cylinder casting. There is one very interesting feature regarding the actual cooling arrangement for the cylinders, for a pressed-steel cover is fitted on the off side of the unit, through which passes a portion of the water. There is a passage formed in this pressing, with holes situated along the interior face which are exactly opposite to the spaces between each pair of cylinder walls. Water is therefore squirted straight through the spaces on to the valve side of the engine, and by a graded arrangement of holes in the plate each valve pocket receives an equal amount of water.

Before concluding, reference should be made to the rather ingenious arrangement of the inlet and exhaust manifolds. These are placed one above the other, the former being uppermost. The exhaust manifold is very wide in a plan view and a passage is cast through it to convey the mixture from the carburetter (which is situated below the exhaust manifold) to the inlet pipe, a hot-spot being formed at the juncture of the two pipes. The exhaust gases are led away from the front, Altogether a fine unit, which, although planned on straightforward lines, is nevertheless of robust construction and up-to-date design. It weighs approximately 7 cwt. 2 qrs. 10 lb.

It is quite evident throughout the design that the greatest attention has been paid to details which will make for the efficiency and durability of the engine as a whole. The maker has previously been concerned chiefly in the production of power units for private cars, but this is clearly a sound commercial proposition which should prove suitable for high-speed coaches and other fast vehicles,