MOBILE WELDING PLANT and the Part It Plays in Ships' Repairs

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

AT all the great seaports of this country it is essential that there should be first-class engineering services available, so that if any vessel should need repair that work can be undertaken with the utmost dispatch, to enable the voyage to be resumed with the least Possible loss of earning time.

Welding processes have to be frequently employed to correct boiler troubles and the problem, at the outset, is to get the plant and the tools quickly to the job. As motor vehicles, chiefly of the 3 and 4-ton type, are now available for carrying welding plant and are, in every respect, complete units, the difficulties of workjog are much less onerous than they used to be, and a steamship, once it is berthed in dock where voyage repairs may be carried out, can usually depend upon a welding van being within a few minutes' call.

There are several electric-welding concerns, each of which has a substantial fleet of vehicles operating from Liverpool, including the Premier Electric Welding Co., Ltd., the British ArtWelding Co., Ltd., the Liverpool Electric Welding Co., Ltd., and the Mersey Welding Co., but it is with the transport operations of the first-named that we are im

mediately concerned. This cornB20

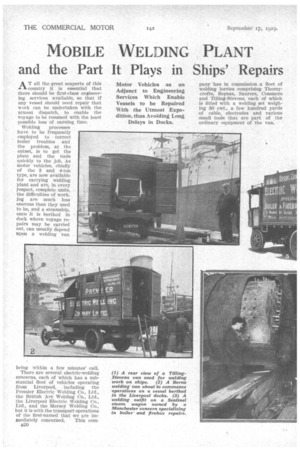

pany has in commission a fleet of welding lorries comprising Thornycrofts, Bernas, Saurers, Commers and Tilling-Stevens, each of which Is fitted with a welding set weighing 30 cwt., a few hundred yards of cable, electrodes and various small tools that are part of the ordinary equipment of the van. The Premier Electric Welding Co., Ltd., of London, manufactures types of welding plant for both direct and alternating current and electrodes for use with all kinds of steel and cast iron, but the Liverpool company is actively engaged in the actual carrying out of electric-welding work, being a contractor to a number of well-known shipping concerns and other under takings. The Premier units are self-contained and do not derive their power from the engine of the motor. The welding plant is, therefore, enclosed in van bodies which are fitted with sling hooks that can be threaded with wire rope, and thus the equipment can be transferred from lorry to lorry, or from the lorry to a station where the plant may be at work for a comparatively long period.

Welding vans are engaged, to some extent, on emergency work and . are, therefore, liable to be called out to undertake, at any hour of the day or night, urgent jobs. Those of the Premier company work mainly on the Mersey dock estate, on both sides of the river, but, occasionally, they journey out of town to places as far distant as 100 miles from Liverpool. When repairs to the hulls of steamers are undertaken and the point of trouble is not accessible from the land side of the quays, use has often to be made of welding plant that is carried in barges which are reserved for that class of work,.

Owners of welding vans specialize in the promptitude of their repairs services, which must be organized to cope with all sorts of contingencies. It is not until a steamer is in port that a proper examination of the power and propulsion plant can be made and, as shipowners are concerned for their vessels to have a quick turn around, no time must be lost in remedying faults which are revealed by the machinery surveyors. That obviously makes it difficult for the operators of vehicles to anticipate what demands are likely to be made on them, even within the short space

of 24 hours. There might be stretches of day-and-night work, followed by periods of time when the vans have to wait for the next job to present itself. End-of-voyage repairs are always rush jobs, the flow of which cannot be predetermined with any• accuracy.

In contrast with this class of work, there is

'what is known as lay-up or overhaul operations, when steamers, after working on a season's cruise, are dry-docked and thoroughly sur veyed. Some of these contracts take a long time to complete and necessitate the welding van being on the spot for, perhaps, weeks on end.

When the motors are working in the Liverpool docks, alongside a steamer. they are not allowed to B21 take up a stand longer than the ordinary working day, unless the electricity required be purchased from the Mersey Docks and Har bour Board. To overcome this handicap, therefore, when big jobs are on hand, the motor generator set is placed on a trailer and derives its power supply from the dock authority.

Through working in such a small, but dense, industrial area as Merseyside, travelling time and distances are small, and it is only on rare occasions that the mileage per vehicle per day exceeds 10, as the

rest of the working 'clay is spent on the particular contract to which the motor has been sent.

The Premier Electric Welding Co., Ltd., undertakes all the repairs to its rolling stock and plant, but as the transport operation is, in a sense, subsidiary to the welding process, which is the one that brings in the revenue, it is not considered -necessary to make any elaborate calculations concerning the matter of running costs. Each one of the company's motors is staffed by three men—a driver and two welders,