Contributions from Drivers and Mechanics.

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Ten Shillings Weekly for the Best Communication Received, and One Penny a Line of ten words For anything else published.

Drivers of commercial motors, and mechanics and [return of garages or shops, who are engaged in any branch of the industry, are invited to contribute short, personal experiences, opinions or suggestions, on subjects which are likely to trove of interest to our readers. We shall be glad to hear of anything interesting that has conic under any driver's or mechanic's notice, either in the shops Or on the road. Long and successful runs ; services with no "lost journeys" ; workshop tips and smart repairs ; all arc suitable subjects. Send a post-card, or a letter, or a sketch to us---no matter how short, or how written, OY how worded. We will "knock it into shape" before publication. When writing it is as well to mention your employer's name as a guarantee of bona fides (not for Publication), and to state whether you wish your van name, or initiois only, to be published. Payment will be made immediately after Publication. Address your letters to The Editor, " T H F. COMMERCIAL MOTOR," 7-15, Rosebery Avenue, London, E.G.

Postal Communications.

We have replied in full to the following correspondents by post, as their communications were not of sufficient general interest to varrant publication :—" T.T." (Wimbledon Park, S.W.); Percy Howls (Worthing,); and E. M. F. Johns (Grantham). The photographs submitted by J. Colson (Norwich) are too indistinct for reproduction.

A Road Spring in Splints.

Tim sender of the following communication has been awarded the los. prize this week.

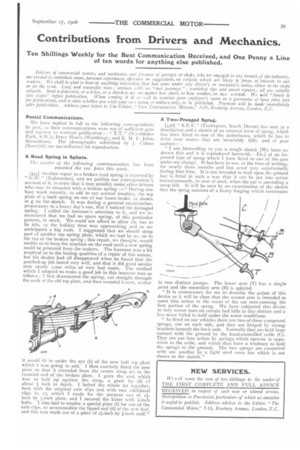

[435] Another repair to a broken road spring is reported by " G.W." (Todmorden), and we publish our correspondent's account of it, in order that it may possibly assist other drivers who may be stranded with a broken spring :—" During one busy week recently, to add to our normal troubles, the top plate of a back spring on one of our buses broke, as shown at g on the sketch. It was during a general examination, preparatory to a heavy day's run, that I noticed the damaged spring. I called the foreman's attention to it, and we remembered that we had no spare spring, of this particular pattern, in stock. We could not afford to allow the bus to lie idle, as the holiday time was approaching and as we anticipated a big rush. I suggested that we should strap part of another top spring plate, which we had by us, on to the top of the broken spring; this repair, we thought, would enable us to keep the machine on the road until a new spring could be procured from the makers. The foreman was a bit sceptical as to the lasting qualities of a repair of this nature, but his doubts had all disappeared when he found that the patched-up job lasted very well, and that it did good service over nearly 1,000 miles of very bad roads. The method which I adopted to make a good job in this instance was as follows : I first dismounted: the spring, cut straight through the neck of the old top plate, and then rounded it over, so that it would tit in under the eye (b) of the new half top plate which I was going to add. I then carefully fitted the new piece so that it extended from the centre strap (c) to the rounded end of the broken plate. I gave the end, which was to butt up against the strap, a good lip (d) cf about ,t inch in depth. I bolted the whole lot together, both with the original axle clips and with two additional clips (e, e), which I made for the purpose out of inch by plate, and I secured the latter with /-inch bolts. I also had to employ a special plate (1) for one of the axle clips, to accommodate the lipped end (d) of the new leaf, and this was made out of a piece of 21-inch by-,3-inch stuff." A Two-Pronged sprag.

[436] " S.E.E." (Yealmpton, South Devon) has sent in a description and a sketch of an unusual form of sprag, which has been fitted to one of the motorbuses, which he has to drive over routes that are invariably hilly and of poor sui face :—

" I am forwarding to you a rough sketch [We have redrawn this and it is reproduced herewith.—En.] of an improved typo of sprag which I have fitted to one of the cars under my charge, It has been in use, at the time of writing, for nearly three months and has acted very satisfactorily during that time. It is not intended to trail upon the ground but is fitted in such a way that it can be put into action instantaneously, in case of need, when the car is ascending a steep hill. It will be seen by an examination of the sketch that the sprag consists of a heavy forging which terminates in two distinct prongs. The lower arm (T) has a single point and the secondary arm (B) is splayed.

"It is unnecessary for me to describe the action of this device as it will be clear that the second arm is intended to come into action in the event of the car over-running the first portion of the sprag-. We have subjected this device to very severe tests on certain bad hills in this. district and it has never failed to hold under the worst conditions.

" As fitted on our vehicles there are two of these compound sprags, one on each side, and they are hinged by strong brackets beneath the back axle. Normally they are held from contact with the ground by the hand-controlled cable (C). They are put into action by springs which operate in opposition to the cable, and which thus have a tendency to hold the sprags to the ground. The two sprags are connected with one another by a light steel cross bar which is not shown in the sketch."