Testing tip top technoLogy

Page 32

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

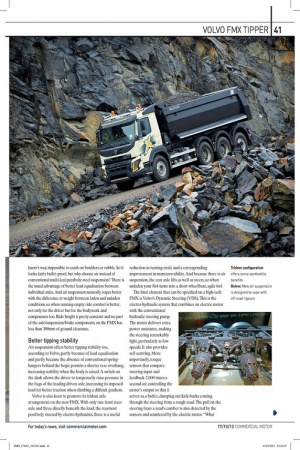

Is this what the next generation of 8x4 tippers will look like? CM tries Volvo's new FMX, laden with 20 tonnes of Swedish stone and all the latest technology By David Wilcox YOU'RE IN THE market for a new 8x4 tipper, and it's got to be tough, rugged, durable. Or perhaps you are forward-thinking, keen to take advantage of the latest vehicle technology. Volvo Trucks claims these two approaches need not be mutually exclusive. According to company president Claes Nilsson, its Euro-6 FMX is "the most robust truck we've ever made7And if you specify it with Volvo's latest technology, there is no doubt that it

will also be just about the most sophisticated tipper money can buy.

Not that long ago, it was pretty bold to opt for an automated gearbox in an 8x4 that needed to go off-road. Nowadays, around 90% of Volvo's 8x4 chassis in the UK are specified with the 12-speed I-Shift gearbox. But will there be a similar pattern of uptake for Volvo's newest innovations for the FMX? Let's start with rear airsuspension. This is not standard road-going air suspension, rarely chosen by tipper operators — this is GRAS-G2, newly purpose-designed to cope with off-road as well as on-road duties and available on one-, twoor three-axle bogies. There are four heavy-duty air-bags for each axle, tucked high up and as closely as possible to the axle-beam to keep everything within the arc of the tyre's diameter for maximum protection. Similarly, the U-shaped anti-roll bars, one for each axle, are at an inclined angle and anchored to the chassis in the centre of the bogie, keeping them out of

harm's way, impossible to catch on boulders or rubble. So it looks fairly bullet-proof, but why choose air instead of conventional multi-leaf parabolic steel suspension? There is the usual advantage of better load equalisation between individual axles. And air suspension naturally copes better with the difference in weight between laden and unladen conditions, so when running empty ride comfort is better, not only for the driver but for the bodywork and components too. Ride height is pretty constant and no part of the axle/suspension/brake components on the FM X has less than 300mm of ground clearance.

Better tipping stability

Air suspension offers better tipping stability too, according to Volvo, partly because of load equalisation and partly because the absence of conventional springhangers behind the bogie permits a shorter rear overhang, increasing stability when the body is raised. A switch on the dash allows the driver to temporarily raise pressure in the bags of the leading driven axle, increasing its imposed load for better traction when climbing a difficult gradient. Volvo is also keen to promote its tridem axle arrangement on the new FMX. With only one front steer axle and three directly beneath the load, the rearmost positively steered by electro-hydraulics, there is a useful

reduction in turning circle and a corresponding improvement in manoeuvrability. And because there is air suspension, the rear axle lifts as well as steers, so when unladen your 8x4 turns into a short-wheelbase, agile 6x4. The final element that can be specified on a high-tech FM X is Volvo's Dynamic Steering (VDS). This is the electro-hydraulic system that combines an electric motor with the conventional hydraulic steering pump. The motor delivers extra power assistance, making the steering remarkably light, particularly at low speeds. It also provides self-centring. More importantly, torque sensors that compare steering input and feedback 2,000 times a second are controlling the motor's output so that it serves as a buffer, damping out kick-backs coming through the steering from a rough road. The pull on the steering from a road's camber is also detected by the sensors and countered by the electric motor. "What

I-Shift did for gearboxes, this will do for steering," claims Volvo. It is not alone in championing this principle: Mercedes-Benz offers a similar electro-hydraulic assistance system, ZF's Servotwin, on its new Arocs construction vehicles.

So much for the theory — how does all this technology work in practice? After driving a conventional 8x4 FM X, with I-Shift but standard steering and multi-leaf steel suspension, we were able to compare it with the high-tech alternative — a tridem configuration 8x4 with VDS and rear air-suspension. The location was a quarry in Sweden, not far from Volvo's Gothenburg factory.

No more kick-back

Of the three technologies, VDS was by far the most immediately discernible. It had already impressed us on the road, fitted to an FM tractor unit (CM 29 August) but it really shines off-road on rough, irregular surfaces where a driver normally has to put in more effort and concentration. Not with VDS: ruts and potholes are magically dialled out by the torque input from the electric motor, so you just go where you aim, with no kick-back from the wheel. It is truly uncanny. VDS goes nicely with the tridem configuration. VDS removes the effort and adds precision while tridem provides manoeuvrability to negotiate a remarkably tight course. The rear-steer axle has auto-lift, dropping as soon as the load goes on. At present, if you want VDS on your FMX you have to choose tridem rather than the

conventional 8x4 because we are told that it is likely to be 2015 before Volvo offers VDS with twin-steer front axles. After the revelations of VDS and the tridem configuration, air suspension seems less remarkable, but was nevertheless apparent in terms of the improvement in ride quality. Air already has a legislative blessing as the essential ingredient of 'road-friendly suspension' so there is little doubt it should be the suspension medium of choice. 'Road-friendly' implies truck-friendly too, so it is

reasonable to expect that chassis and body components should feel the benefit of an easier ride.

It is hard not to be impressed by a VDS-equipped, air-suspended, tridem FMX 460 8x4 but can such futuristic options earn their keep in a sector not renowned for luxury extras, other than the occasional excess of lights and air-horns? Is this just an interesting aside or will all tippers look like this come 2020?

The tridem configuration costs around £2,000 more than a conventional 8x4 FMX. Ticking the VDS option box adds another £2,700. And if you opt for air suspension instead of the usual B-ride multi-leaf steel the bill goes up by a further £3,600. So all three together add up to a list price hike of over £8,000— or about 9% on the vehicle's overall price.

Volvo attempts to make a business case for VDS by linking the assistance it gives to a reduction in fatigue and wear-and-tear injuries to drivers' shoulders and backs.

That pays off in better productivity and less sick leave, argues Volvo.

What's not to like?

Without hard data it is impossible to prove or disprove this, but there is no doubt that a tipper driver with site work or on short shuttle runs with plenty of reversing, when steering loads are highest, is more likely to feel the benefit than a night trunker on the motorway.

An on-cost of 'only' £2,000 or so at least makes it easier to choose tridem.

Better manoeuvrability, the ability to lift an axle to save tyre wear and enhance traction — what's not to like? Other manufacturers also offer tridem chassis and we suspect the configuration will win over an increasing number of UK multi-wheeler operators, given time. If it allows bigger trucks to get into places more easily, or more speedily and with less damage, the productivity gains are obvious.

As the most expensive of the options, air suspension, is perhaps the most difficult to justify. Perhaps it is best to come at it the other way, and ask why not? If air suspension is commonplace on tractor units and trailers, why not on tippers too? More work needs to be done to translate the engineering theory into fully costed operational benefits. As regards the crucial issue of weight, Volvo engineers say an air-suspended tridem FMX is no heavier than a conventional 8x4 on steel. •