REDUCING FORD LUBRICATION DIFFICULTIES.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

A Very Simple Fitting which is Claimed to Maintain a Regular Supply of Lubricant to Engine Cylinders on Hills.

THERE ARE certain lubrication troubles from which it is a matter of common knowledge the Ford engine suffers. When the vehicle is standing on level ground, and the engine is running, the flywheel, recating in the eil bath which constitutes. the lowest portion of the crankcase, picks up the oil that drains thereinto and splashes it over the gears, clutch, brake bands, etc., and the magnets on the flywheel, acting as scoops, each in turn, carry upwards a small quantity, and at a point near the top of the flywheel discharge the oil into a funnel which , communicates with a pipe, which then conveys it to the forward end of the crankcase and discharges it under the front end bearing. The oil then flows into the troughs under the big-ends, whese the latter pick it up and throw it on to the bearings, wristpins and cylinder walls. As .the nit drains down it tends to overflow the troughs and then finds its lowest level

• again in the flywheel pit.

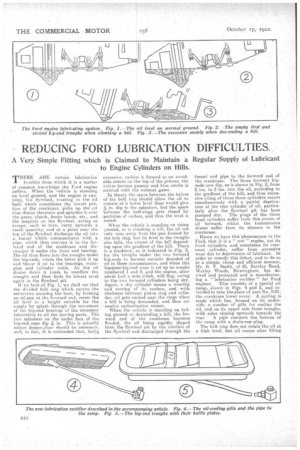

If we look at Fig. 1, we shall see that the divided bolt ring which carries the set-screws securing the base, by forming an oil-pan at the forward end; raises the oil level to a height suitable for the supply 'by splash through the movement of the big-end bearings of the necessary lubrication to all the moving parts. The two splashers on the under .face of the big-end caps dip pg in. This is actually rather deeper.than should be necessary, and, in fact, it is contended that, being

excessive, carbon is formed to an avoidable extent on the top of the pistons, the valves become gummy and blue smoke is emitted with the exhaust gases.

In theory the space between the halves of the bolt ring should allow the oil to remain at a lower level than would give in. dip to the splashers, but the space between the half-rings gets closed by particles of carbon, and thus the level is raised.

When the vehicle is standing on rising ground, or is climbing a hill, the oil not only runs away from the pan formed by the bolt ring, but its level in the troughs also falls, the extent of the fall depending upon the gradient of the hill. There is a tendency, as is indicated in Fig. 2, for the troughs under the two forward big-ends to become entirely denuded of oil in these circumstances, and when this happens big_end wear is set up on cranks numbered 1 and 2, and the engine, after about half a mile climb, will flag, owing to the two forward cylinders being dry. Again, a dry cylinder means a wearing and scoring of its surface, and with slackness,between piston ring and cylinder, oil gets sucked past the rings when a hill is being descended, and then excessive carbonisation ensues.

When the vehicle is standing on falling ground or descending a bill, the forward end of the crankcase becomes flooded, the oil being rapidly dipped from the flywheel pit by the rotation of the flywheel and discharged through the funnel and pipe to the forward end of the crankcase. The three forward bigends now dip, as is shown in Fig. 3, from 2 ins, to 3 ins, into the oil, according to the gradient of the hill, and thus excessive oiling of those three cylinders occurs simultaneously with a partial deprivation of the rear cylinder of oil, particularly after the flywheel pit has been pumped dry. The plugs of the three front cylinders suffer from this excess of oil forward, whilst the transmission drums suffer from its absence in the crankcase.

Renee we have this phenomenon in the Ford, that it is a " wet " engine, yet its front cylinders, .and sometimes its rearmost cylinder,. suffer from excessive wear due to deprivation of lubricant. In order to remedy this defect, and to do so in a simple, cheap and efficient manner, Mr. B. V. Smith, of 85, Barclay Road, Warley Woods, Birmingham, lips devised and protected and is manufacturing a "lubrication rectifier " for Ford

engines. This consists. of a special oil sump, shown in Figs. 4 and 5, and intended to take the place of part. No. 3101, the crankcase lower cover. A casting is made which has, formed on its underside, a number cif gills for cooling the oil, and on its upper side three troughs, with .sides sloping upwards towards the

rear. A pipe connects the bottom of the sump with a drain-cup plug.

The bolt ring does not retain the oil at a high level, but all excess after filling the troughs is drained off through the pipe to the flywheel pit, and owing to the presence of the ribs the oil is adequately cooled, thus partially restoring its viscosity. When a vehicle is standing on level ground the oil level in the troughs is no higher than the front lip of the trough, and thus the dip of the big-end splashers is reduced to 1-16th in., which gives adequate lubrication,

this being indicated in Fig. 6. The tendency to excessive carbonization is thus materially reduced, the valves do not get gummy, the oil consumption is improved and the engine and plugs keep clean and dry.

When a hill is -being climbed the slope brings the deeper section of the troughs into play, because of the higher level of the vertical baffles, as shown in Fig. 7, and the oil supply is thus increased slightly, the rear cylinder and fourth big-end bearing getting all the oil necessally -because of their nearness to the

flywheel. The chance of the forward cylinders being starved of lubricant is thus removed, and, in consequence, the engine will not flag on a very steep gradient ;, the maximum dip of the splashers is about in. In Fig.. 8 will be seen indicated the state of affairs when the vehicle is descending a hill. The oil which is fed.forward is drained into the troughs and the excess escapes through the pipe to the flywheel pit, thus ensuring two desiderata, namely, no more than a suffictency of oil to the forward cylinders and a sufficiency to the transmission case. The dip of the splashers when a gradient of 1 in 5 is being descended is about in. with this arrangement.

We are informed that a number of these rectifiers are in use and that they are giving satisfaction, the engines runfling more sweetly, pulling better, consuming less oil, and even giving increased speed.