UPKEEP OF COMMERCIAL ELECTRIC VEHICLES.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

The Seventh Article.

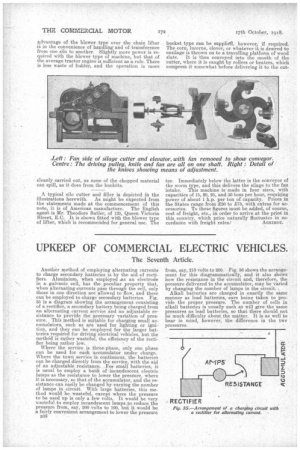

Another method of employing alternating currents to charge secondary batteries is by the aid of rectifiers. Aluminium, when employed .as an electrode in a galvanic cell, has the peculiar property that, when alternatingcurrents pass through the cell, only those in one direction are allowed to flow, and these can be employed to charge secondary batteries. Fig. 35 is a diagram showing the arrangement consisting of a rectifier, a secondary battery being charged from an alternating current service and an adjustable resistance to provide the ueeessary variation of pressure. This method is suitable for charging small accumulators, such as are used for lighting or ignition, and they can be employed for the larger batteries required for driving electrical vehicles, but the methca is rather wasteful, the efficiency of the rectifier being rather low. Where the service is three-phase, only one phase can be used for each accumulator under charge. Where the town service is continuous, the batteries can be charged directly from the servite, with the aid of an adjustable resistance. For small batteries, it is usual to employ a bank of incandescent electric lamps as the resistance to lower the pressure, where it is necessary, so that of the accumulator, and the resistance can easily be changed by-varying the number of lamps in circuit. With large batteries, this method would be wasteful, except where the pressure to be used up is only a few volts. It would be very wasteful to employ incandescent lamps to reduce the pressure from, say, 200 volts to 100, but it would be a fairly convenient arrangement to lower the pressure

B38

from, say, 210 volts to 200. Fig. 36 shows the arrangement for this diagrammatically, and it also shows how the resistance in the circuit and, therefore, the pressure delivered to the accumulator, may be varied by changing the number of lamps in the circuit. Alkali batteries are charged in exactly the same manner as lead batteries, care being taken to provide the proper pressure. The number of cells in alkali batteries is usually such as will give the same pressures as lead batteries, so that there should not be much difficulty about the _matter. It is as well to bear in mind, however, the difference in the two pressures.

Charging Plugs.

Where a number of vehicles are owned by one firm, and also where the vehicles themselves are run into the charging stations, connection is usually made to the charging current service by means of flexible conductors, similar to those used with incandescent lamps, but very much heavier and stronger, and more easefully protected, each end of the conductor being attached to a connecting plug, a standard form of. which is shown in Fig. 47. The connecting plug for this purpose is a development of the wall plug, with which everyone is pretty familiar, used for connect mg portable electric, lamps, electric radiators, etc., to the electric service.

There is a plug fixed on the switchboard of the charging station, similar to those fixed on the walls of dwelling rooms, etc. It carries two contacts connected to the two wires of the service, and the plug attached to the flexible cable also carries two contacts which engage with those in the fitting on the switchboard, the plug at the other end of the flexible cable making connections to a similar fitting fixed usually in the front of the vehicle. The fittings at the ends of the flexible cables and in the front of the vehicle are usually provided with covers, which keep the dust out when the fittings are not in use.

The fitting on the vehicle and the plug are also possible sources of trouble. If moisture and dirt are allowed to accumulate between the contacts in the fitting on the vehicle, another leakage path_ will be formed, and if dirt is allowed to accumulate between the contacts 9n either of the plugs, the charging current will have leakage paths open to it, across which a certain portion of the current-will flow, instead of passing through the, battery, so that the battery will take longer to charge, and if the trouble has been allowed to go very far, it may not be possible to secure a charge at all. In addition, sparking may take place at the contact that will very seriously increase the trouble. It is important, therefore, that all the contacts engaged in the operation of charging should be frequently examined and kept absolutely clean and above all things dry.

Boosting.

By boosting, a term imported from America, is meant giving the batteries a short charge, say, during the dinner hour, or at any other convenient time, when the vehicle is standing temporarily idle. The operation of boosting is exactly the same as that of charging and is carried out in exactly the same manner, but the current is usually only applied for an hour, or even less, instead of the usual 5 to 10 hours. A boosting charge is usually applied at a little higher pressure than the ordinary charging current. A test with a portable voltmeter will show the pressure of the battery, also the amnere-hour meter that is usually employed, will show how much has been taken out of the battery, and a little experience will soon enable drivers to estimate how much boosting charge to put in. The San-gamo meter, which is largely employed with electrical vehicles, shows exactly the condition of the battery at any instant, and it is also provided that, when the battery is fully charged, the pointer on the dial returns to zero, so that the driver should have full control.

Braking Electric Vehicles.

Electric vehicles are fitted with .mechanical brakes, usually one worked by a lever close to the driver's hand and the other by his foot. They are usually band brakes, sometimes expanding inside a drum and sometimes clasping the outside of the drum.

A.good deal has been made from time to time of the possibility of using the motor itself as a brake when running down hill, by causing it to run as a. generator and to deliver a, charging current to the battery. In practice it has been found best not to employ this arrangement because of the additional complication and because of the difficulty of arranging, when regeneration is employed, for another very important matter, ensuring that the battery shall be disconnected when the brakes are on. In modern electrical vehicles, it is always arranged when the brakes are applied fully, for stepping the vehicle or when running downhill, that the controller shall return to the neutral 'position, where the battery is disconnected from everything. One of the troubles that has been met with in the past has been the waste of current due to the battery being connected when the brake is en.

[This series of technical articles is concluded with the present contribution. They have purposely been kept within nari•ow limits, and that this method of treating the subject has been appreciated we have full evidence. Owners of electric vehicles have placed the information thus rendered available in the hands of their employees with, we hope, useful results.—En. TEE COMMERCIAL MOTOR.1