• AGRIMOTOR NOTES.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

The Use of Silos and Silage Cutters in Great Britain.

In a recent note I -referred to the silo, which is gradually coming into use in this country. The subbct is important ,enough to merit further reference in these balm:nits, as the conversion of the crops into silage and their subsequent elevation into the silo itself are operations which call for power, the provision of which becomes, not unnaturally, a. further demand upon the agrimetor engine. The use of silage as fodder is not unknown or novel in this country. Its manufacture from various crops and its preservation on the most improved and modern lines, by being cut finally and stored in a well-built tower or similar erection above the ground, is, however. In this respect we stand where our American cousins did about 30 years ago. Silos and silage are now widely known and used throughout the States, and as the benefits derived from their use increase very considerably in proportion to the value of the land, it follows that so soon as the real merits of the system become known, rapid and widespread adoption in this country will ensub. I should add that signs of this recognition are already manifest in many districts, particularly in Norfolk, where, apparently, the first modern silo to be used in this country was erected.

After the selection, growth and harvesting of the crops, there are still two processes to be effected, the cutting of the fodder into short lengths—about in. is good practice—and its deposition inside the 'silo. As the latter may be anythingiup to 60 ft. in height, sometimes even more, it is clearly no matter for hand work. The two operations are usually performed by the one machine, which is practically self-contained. The fodder is fed into the maw of a revolving knife, either of the disc or cylinder type. It falls thence into a conveyor, from whence it is lifted to the silo. The principal difference between the two main classes of silo fillers is in connection with-the method of lifting. Either an endless chain.of buckets May be used or a blower.

The bucket type is the older form, and is now, to some extent, being superseded by the blower type. The latter is usually in the form of a powerful fan, which sticks the cut silage from the cutter, and blows it up a vertical delivery pipe, the top of which is bent over the top edge of the waIl of the silo. The principal

advantage of the blower type over the chain lifter is in the convenience of' handlingand of transference from one silo to another. Slightly more power is required with the blower type of machine, but that ,of the average tractor engine is sufficient as a rule. There is less waste of fodder, and the operation is more

cleanly carried out, as none of the chopped material can spill, as it does from the buckets.

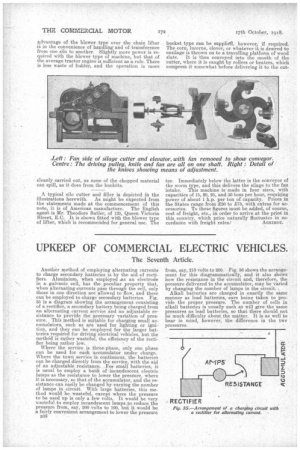

A typical silo cutter and filler is depicted in the illustrations herewith. As might be expected from the statements made at the commencement of this note, it is of American manufacture. The English agent is Mr. Theodore Butler, of 139, Queen Victoria Street, E.C. It is shown fitted with the blower type of lifter, which is recommended for general use. The

bucket type can be supplied, however, if required. The corn, lucerne, clover, or whatever it is desired to ensilage is thrown on to a travelling platform of wood slats. It is thus conveyed into the mouth of the cutter, where it is caught by rollers or beaters, which compress it somewhat before delivering it to the cut-.

ter. Immediately below the latter is the conveyor of the worm type, and this delivers the silage to the fan intake. This machine is made in four sizes, with capacities of 15, 20, 25, and 30 tons per hour, requiring power of about 1 h.p. per ton of capacity. Prices in the States range from 250 to 275, with extras for accessories. To these figures must be added, of course, cost of freight, etc., in order to arrive at the price in this country, which price naturally fluctuates in ac cordance with freight rates.' AGRIMOT.