BIGNESS

Page 73

Page 74

Page 79

Page 80

Page 81

If you've noticed an error in this article please click here to report it so we can fix it.

with international flavour

BY .P. A. C. BROCK1NGTON, AMIMechE THE DISADVANTAGE of space short-1age at the Glasgow Show has grown more acute with the advent of the latest C and U Regulations and the necessity for exhibitors to display heavier goods vehicles equipped to cater for attendant developments in national and international traffic.

To a greater extent than was evident at the 1965 Show, the goods-body displays this year represent a determined attempt on the part of a substantial minority of exhibitors to demonstrate that they are "with it" in providing for such developments. And the exhibition of 82/83-seat double deckers on 33ft chassis is complementary to this endeavour with regard to loadcarrying facility.

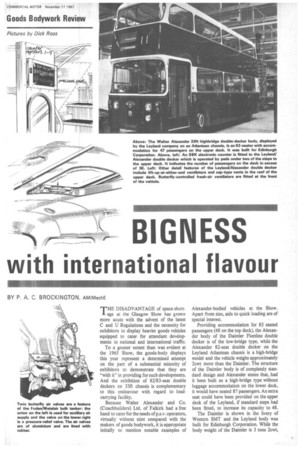

Because Walter Alexander and Co. (Coachbuilders) Ltd. of Falkirk had a free hand to cater for the needs of p.s.v. operators, virtually without stint compared with the makers of goods bodywork, it is appropriate initially to mention notable examples of Alexander-bodied vehicles at the Show. Apart from size, aids to quick loading are of special interest.

Providing accommodation for 83 seated passengers (48 on the top deck), the Alexander body of the Daimler Fleetline double decker is of the low-bridge type, while the Alexander 82-seat double decker on the Leyland Atlantean chassis is a high-bridge model and the vehicle weighs approximately 2cwt more than the Daimler. The structure of the Daimler body is of completely standard design and Alexander states that, had it been built as a high-bridge type without luggage accommodation on the lower deck, it would have seated 87 passengers. An extra seat could have been provided on the upper deck of the Leyland, if standard steps had been fitted, to increase its capacity to 48.

The Daimler is shown in the livery of Western SMT and the Leyland body was built for Edinburgh Corporation. While the body weight of the Daimler is 3 tons 2cwt, the Leyland body weighs 3 tons 1 levet.

An SBK electronic seat counter is fitted to the Leyland and would obviously offer particular advantages for one-man operation of double deckers. It indicates the entrance and exit of the "last nine" top-deck passengers, an illuminated panel facing the entrance giving the number of seats available on the upper deck after the entrance of the 38th passenger. The counter is to be employed as standard equipment by Coventry Corporation.

Available seats are also indicated on the driver's instrument board. Both indicators are wired to two pads operated by steps leading to the upper deck and whether the indicator shows an increase or a decrease depends on the sequence of weight transfer; the second step to take the weight of the passenger sends the appropriate signal to the indicators.

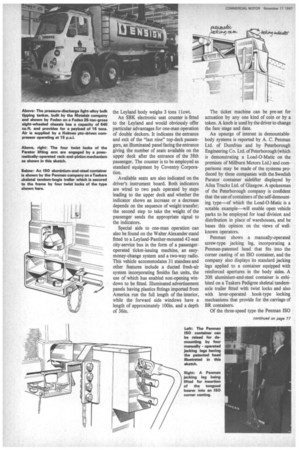

Special aids to one-man operation can also be found on the Walter Alexander stand fitted to a Leyland-Panther-mounted 42-seat city-service bus in the form of a passengeroperated ticket-issuing machine, an easymoney-change system and a two-way radio, This vehicle accommodates 31 standees and other features include a ducted fresh-air system incorporating Smiths fan units, the use of which has enabled non-opening windows to be fitted. Illuminated advertisement panels having plastics fittings imported from America run the full length of the interior, while the forward side windows have a length of approximately 100in, and a depth of 36in. The ticket machine can be pre-set for actuation by any one kind of coin or by a token. A knob is used by the driver to change the fare stage and date.

An upsurge of interest in demountablebody systems is reported by A. C. Penman Ltd. of Dumfries and by Peterborough Engineering Co. Ltd. of Peterborough (which is demonstrating a Load-O-Matie on the premises of Millburn Motors Ltd.) and comparisons may be made of the systems produced by these companies with the Swedish Parator container sidelifter displayed by Ailsa Trucks Ltd. of Glasgow. A spokesman of the Peterborough company is confident that the use of containers of the self-demounting type—of which the Load-O-Matic is a notable example—will enable open vehicle parks to be employed for load division and distribution in place of warehouses, and he bases this opinion on the views of wellknown operators.

Penman shows a manually-operated screw-type jacking leg, incorporating a Penman-patented head that fits into the corner casting of an ISO container, and the company also displays its standard jacking legs applied to a container equipped with reinforced apertures in the body sides. A 20ft aluminium-and-steel container is exhibited on a Taskers Pedigree skeletal tandemaxle trailer fitted with twist locks and also with lever-operated hook-type locking mechanisms that provide for the carriage of BR containers.

Of the three-speed type the Penman ISO jacking leg can be handled by two men and the container is raised for demounting by four legs in two stages. Firstly, the lifting bearer of the leg is "partially inserted" in the corner casting and the corner is raised a few inches to clear the twist-lock; a spacer is then placed between the corner and the vehicle frame, the load on the leg is released and the bearer is fully inserted in to the corner. Detail features of the container include Joloda tracks.

The latest type of standard demountable body produced by Penman is located on three cross-members, attached to the skeletal frame of the vehicle, which are designed to locate the body correctly when it is being lowered.

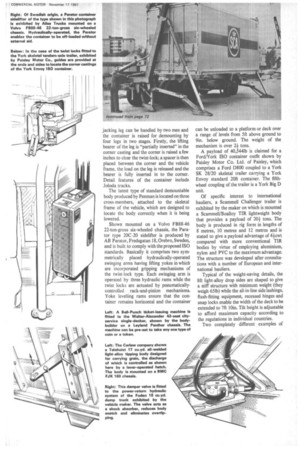

Shown mounted on a Volvo F888-46 22-ton-gross six-wheeled chassis, the Parator type 20C-20 sidelifter is produced by AB Parator, Fredsgatan 18, Orebro, Sweden, and is built to comply with the proposed ISO standards. Basically it comprises two symmetrically placed hydraulically-operated swinging arms having lifting yokes in which are incorporated gripping mechanisms of the twist-lock type. Each swinging arm is operated by three hydraulic rams while the twist locks are actuated by pneumaticallycontrolled rack-and-pinion mechanisms. Yoke levelling rams ensure that the container remains horizontal and the container can be unloaded to a platform or deck over a range of levels from 5ft above ground to 9in. below ground. The weight of the mechanism is over 24tons.

A payload of 40,5441b is claimed for a Ford/York ISO container outfit shown by Paisley Motor Co. Ltd. of Paisley, which comprises a Ford D800 coupled to a York SK 28/20 skeletal trailer carrying a York Envoy standard 20ft container. The fifthwheel coupling of the trailer is a York Big D unit.

Of specific interest to international hauliers, a Scammell Challenger trailer is exhibited by the maker on which is mounted a Scammell/Boalloy TIR lightweight body that provides a payload of 20+ tons. The body is produced in rig form in lengths of 8 metres, 10 metres and 12 metres and is stated to give a payload advantage of 44-cwt compared with more conventional TIR bodies by virtue of employing aluminium, nylon and PVC to the maximum advantage. The structure was developed after consultations with a number of European and international hauliers.

Typical of the weight-saving details, the 8ft light-alloy drop sides are shaped to give a stiff structure with minimum weight (they weigh 65 lb) while the all-in-line side lashings, flush-fitting equipment, recessed hinges and snap locks enable the width of the deck to be extended to 7ft 10in. Tilt height is adjustable to afford maximum capacity according to the regulations in individual countries.

Two completely different examples of weight-saving measures are provided by a Stothert and Pitt 6/7 cu.yd. concrete mixer and agitator, exhibited by the British Trailer Company on a W.4351/HD Four-inLine trailer and a pressure-discharge tanker, produced by Metalair Ltd. of Wokingham, which is displayed by the Foden company on a Foden 26-ton-gross eight-wheeled chassis. In the first case a saving of 1,0001b is achieved by mounting the mixer-agitator equipment direct on the frame of a trailer, compared with mounting on an eight-wheeled chassis, and in the case of the tanker a valuable saving is achieved by the use of aluminium hinge-pin brackets and light-alloy air valves.

The concrete-mixer is said to be the first to be mounted on a semi-trailer, and it is notable that the use of an artic enables standard type of equipment to be carried on a suitable road vehicle without infringing the C and U Regulations and that the mixer can, if required, be left on a site without immobilizing the prime mover.

Other BTC exhibits include the lowloading W3018B which can carry a payload of 14 tons and is one of a comparatively new range designed for payloads of 12 tons to 30 tons.

A payload of 16 tons can be carried in the Metalair tanker, the shell, cones and dished ends of which are constructed of 8 s.w.g., +in. and 5 s.w.g. light alloy respectively. The tank has a capacity of 640 cu.ft., while the compressor is a Holmes unit operating at 15 p.s.i. Tipping is provided by an Edbro CAN twin-ram front-of-body gear.

While the Kelvin Hall exhibit of Northern Trailer Co. Ltd. comprises a standard type of 33ft light-alloy-bodied tandem-axle trailer built as a Crown-lock van to carry whisky by the Black and White distillers, the "one that couldn't get in" is' a highly specialized vehicle designed to carry pre-fabricated concrete building sections. This is a stepped semitrailer of 20-ton capacity which has an overall length of 34ft and is equipped with an A-frame superstructure to which the sections are clamped by sliding tubular beams. It is shown in an outside demonstration in Benalder Street.

Important 'outsider' One of the most important "outside" exhibits because of its potential interest to tipper operators generally, an all-steel fixedsided 9 cu.yd. tipping body is being demonstrated by Telehoist Ltd. in the Bedford Cavalcade (exhibit No. 12) which is built of BS968 steel and is claimed to be as light as a comparable aluminium body. Mounted on a Bedford KM 16-ton-gross chassis and equipped with a FR4/163 single-ram frontof-body tipping gear, the vehicle has an unladen weight of only 54 tons.

The tipping gear is one of a new range of single-ram front-mounted heavy-duty units designed to replace twin rams in a number of applications. An FR4 gear is shown with a pump and p.t.o in mock-up form in Kelvin Hall; lifting capacities range up to 30 tons.

A Telehoist Load Lugger lever-arm demountable-container vehicle is shown by James A. Laidlaw (Airdrie) Ltd., Airdrie, mounted on a Ford D 1000 tipper chassis cab. Recently introduced modifications to the Load Lugger enable it to handle skips of any type, which is particularly necessary when the vehicle is purchased by an operator who employs other makes of demountable equipment.

Judging by the reports of standholders exhibiting aluminium-bodied tipping vehicles, it would seem that Scottish operators are more readily prepared than English operators to pay the higher price for these bodies in anticipation of long-term benefits. A number of aluminium-and-timber composite tipping bodies are displayed which are said to offer a tougher, cheaper structure than an all-aluminium type without a substantial weight penalty.