SPOILT FOR (HO CE

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

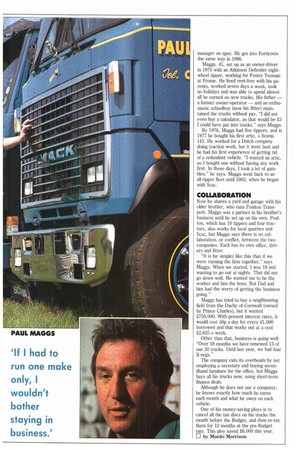

• Each time haulier Paul Maggs buys a new truck, he chooses a different make to the one before. It is not that he is ever particularly dissatisfied with the previous vehicle; it's simply that lorries mean much more than making a living to him — they are the love of his life.

"I buy what I fancy," he says. "If I had to run one make only, I wouldn't bother staying in business — even though I would probably be better off running all. . . say ERFs." Maggs has taken delivery of the first American-built Mack Ultraliner to gain British Type Approval.

His fleet of 12 eight-wheel tippers represent seven of the dozen makes on the market.

As well as the Mack, he runs five tractive units (of three different makes) and two crane lorries, also made by separate manufacturers.

ERF, Leyland Daf, Scania, Mercedes, Seddon Atkinson, Foden and Volvo are all represented. If he had to stick to one or two marques, he would probably choose Scania artics and ERF tippers, he says. But when he approaches dealers, they know him well enough not to try to persuade him to convert wholly to their product, or seek publicity from a sale. "The salesman isn't going to tell everyone on the Mendips about the deal because he knows damn well I'll buy another make next time," he says.

It took 18 months to get permission to run the 38-tonne Ultraliner, imported from Mack's factory in Allentown, Pennsylvania by Western Trucks of Leyland (CM 19-25 April). The manufacturer even had to pay Department of Transport experts to go to the States to test-drive the truck before they deemed it suitable for use in the UK.

Several changes had to be made, including radial front tyres, brakes, indicators and headlamps. It cost Maggs the dollar equivalent of £53,000, including 22% import tax. The Mack is a left-hand-drive model with 261kW (350hp) on tap — "enough for the work we'll do with it" — but with two 568-litre tanks, so it needs refuelling less often than most 38-tonners.

The Mack is not Maggs' first American truck; he has just laid up a W-reg White tractor, which he bought secondhand three years ago; it was one of about 100 assembled by White Concessionaires in Liverpool. He also plans to buy a Peterhilt, and is talking with the local Foden dealer about importing one (Foden's US parent Paccar builds Peterbilts).

Maggs, is turning over about £1. 25m a year from his base at Midsomer Norton in Avon. His tippers work for Foster Yeoman, Wimpey, ARC, Steetley and Stone Suppliers, mostly taking stone and tar from the Mendip Hills to the South of England. He also collects trailers from Portsmouth and other South Coast ports for French-Italian forwarder Scac, and his cranes work for Frome-based concreteblock manufacturer Forticrete.

Transport manager Gary Heavyside joined from Stone Supplies 18 months ago and handles most of the quarry business. He prides himself on being able to have a truck available at short notice at any time. "We don't let anything go by," says Heavyside, who has up to 12 extra drivers on call.

A third of his tippers return with loads. "We have the size of fleet to do jobs an owner-driver couldn't cope with," he says. "Foster Yeoman rang today and we had a truck over in 20 minutes."

Maggs rejects suggestions that quarry work does not pay. "We have had no rate rise from Scac or with our crane work for five years, but we have with tippers," he says. "There are a lot of advantages in working for the quarries. Because we hardly ever operate more than 100 miles from home we can get someone out to a vehicle quickly if it breaks down. We don't need to carry spare tyres, so we don't lose payloads."

Maggs and Heavyside have little involvement on the artic side, as Scac's traffic controller in Portsmouth virtually controls the movements of the subcontractors hauling his trailers by contacting trucks directly. Maggs is one of about 15 hauliers working for Scac; the rest are mainly owner-drivers. He is keen to find other traction customers, but says it is risky taking an artic off Scac work for a one-off job: "We prefer looking for a regular piece of business."

He has been on Scac's books for seven years, after approaching its transport manager on spec. He got into Forticrete the same way in 1986.

Maggs, 41, set up as an owner-driver in 1975 with an Atkinson Defender eightwheel tipper, working for Foster Yeoman at Frome. He lived rent-free with his parents, worked seven days a week, took no holidays and was able to spend almost all he earned on new trucks. His father — a former owner-operator — and an enthusiastic schoolboy (now his fitter) maintained the trucks without pay. "I did not even buy a calculator, as that would be I could have put into trucks," says Maggs.

By 1976, Maggs had five tippers, and in 1977 he bought his first artic, a Scania 141. He worked for a Dutch company doing traction work, but it went bust and he had his first experience of getting rid of a redundant vehicle. "I wanted an artic, so I bought one without having any work first. In those days, I took a lot of gambles," he says. Maggs went back to an all-tipper fleet until 1983, when he began with Scac.

Now he shares a yard and garage with his older brother, who runs Poulton Transport. Maggs was a partner in his brother's business until he set up on his own. Poulton, which has 10 tippers and four tractors, also works for local quarries and Scac, but Maggs says there is no collaboration, or conflict, between the two companies. Each has its own office, drivers and fitter.

"It is far simpler like this than if we were running the firm together," says Maggs. When we started, I was 18 and wanting to go out at nights. That did not go down well. He wanted me to be the worker and him the boss. But Dad and him had the worry of getting the business going."

Maggs has tried to buy a neighbouring field from the Duchy of Cornwall (owned by Prince Charles), but it wanted £750,000. With present interest rates, it would cost 50p a day for every £1,000 borrowed and that works out at a cool £2,625 a week.

Other than that, business is going well: "Over 18 months we have renewed 13 of our 20 trucks. Until last year, we had four X-regs."

The company cuts its overheads by not employing a secretary and buying secondhand furniture for the office, but Maggs buys all his trucks new, using short-term finance deals.

Although he does not use a computer, he knows exactly how much he earns each month and what he owes on each vehicle.

One of his money-saving ploys is to cancel all the tax discs on his trucks the month before the Budget, and then re-tax them for 12 months at the pre-Budget rate. This ploy saved £6,000 this year. LI by Murdo Morrison