RETURN OF THE COMET

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

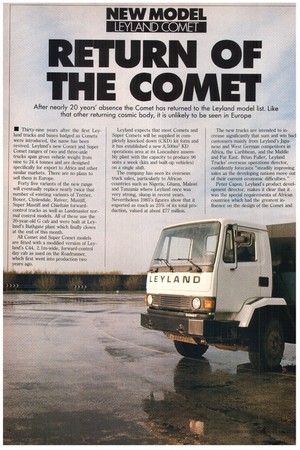

After nearly 20 years' absence the Comet has returned to the Leyland model list. Like that other returning cosmic body, it is unlikely to be seen in Europe

• Thirty-nine years after the first Leyland trucks and buses badged as Comets were introduced, the name has been revived. Leyland's new Comet and Super Comet ranges of two and three-axle trucks span gross vehicle weight from nine to 24.4 tonnes and are designed specifically for export to Africa and other similar markets. There are no plans to sell them in Europe.

Forty five variants of the new range will eventually replace nearly twice that number of existing variants of Terrier, Boxer, Clydesdale, Reiver, Mastiff, Super Mastiff and Chieftain forwardcontrol trucks as well as Landmaster normal control models. All of these use the 20-year-old G cab and were built at Leyland's Bathgate plant which finally closes at the end of this month.

All Comet and Super Comet models are fitted with a modified version of Leyland's C44, 2.1m-wide, forward-control day cab as used on the Roadrunner, which first went into production two years ago.

Leyland expects that most Comets and Super Comets will be supplied in completely knocked down (CKD) kit form and it has established a new 8,500m2 KD operations area at its Lancashire assembly plant with the capacity to produce 96 units a week (kits and built-up vehicles) on a single shift.

The company has seen its overseas truck sales, particularly to African -countries such as Nigeria, Ghana, Malawi and Tanzania where Leyland once was very strong, slump in recent years. Nevertheless 1985's figures show that it exported as much as 25% of its total production, valued at about 277 million. The new trucks are intended to increase significantly that sum and win bacl customers mainly from Leyland's Japanese and West German competitors in Africa, the Caribbean, and the Middle and Far East. Brian Fuller, Leyland Trucks' overseas operations director, confidently forecasts "steadily improving sales as the developing nations move out of their current economic difficulties."

Peter Capon, Leyland's product development director, makes it clear that it was the special requirements of African countries which had the greatest influence on the design of the Comet and

per Comet. After a month-long tour of .veral of them, a team of four senior agineers concluded that Leyland's 3tablished test programme for new thick development did not come close iough to simulating actual operating conlions in those countries, where the surces of what metalled roads there are we deteriorated badly and where the Drina] truck route is a rough dirt track. The usual 3,200km pave test which recedes most European trucks' final enineering sign-off were deemed to be ot severe enough for the 250 and 255 roject trucks, as they were called beire the Cornet name re-emerged. A ew "overseas development", off-road -ack was built at the Leyland Technical entre proving ground.

Having recently driven a laden 4x2 :omet around this 3.2krn track we can ouch for the exceptional severity of the hassis racking it induces. To simulate -le badly broken and pot-holed metalled aad surfaces they had found in Africa, ,eyland's engineers built two new secons on the on-road part of their proving round, one with rectangular granite locks set in a concrete base and pro

uding above its surface, and the ther with 50min deep sets. On both aese sections the sets are scattered in random pattern. The complete durabil.y test programme for Comet and Super ;omet included 385km over the 25mm ets, 100km over the 50min sets (in both ases at a speed of about 451trn/h). ,045km on the off-road track and ,190kni on pave. By gathering data from istrumented trucks being put through this test programme, the engineers at Leyland have also been able to develop realistically severe computer-controlled rig tests for individual Comet components and systems.

TEE CAB

The major attraction of the C44 cab for use on the Comet and Super Comet was its suitability for CKD. It has only seven major panels and no separate sub-frame, and therefore is easy to pack and assemble without special equipment.

Pave testing of the C44 during Roadrunner development had proven the cab's durability for normal European use. The only weakness revealed by Leyland's special export vehicle test programme was in the front mounting area of the floor panel. The strengthened panel which was

developed for Cornet and Super Comet is now used on Roadrunner as .well.

There are some obvious differences between the C44 cab fitted to Comet and Super Comet and that used on Roadrunner. On the new models the asymmetric front panel with kerb window cut-out is replaced by a plain, full-width steel panel, and the Roadrunner's homofocal headlights are replaced by conventional circular lens components.

Also different is the bumper. Roadrunner's reinforced plastic composite bumper clearly does not lend itself to repair in the African bush. The Comet and Super Comet's bumper is a simple, but very stout, steel one.

The cab is mounted relatively high on the Comet and Super Comet chassis, mainly for good ground clearance, but also to help overcome the problem of poor visibility in sub-tropical early morning ground mist, which Leyland engineers found to be common in target markets.

One disadvantage of the extra height however, is that the Comet cannot be driven inside a Hercules transport aircraft, and this means that it cannot be a contender for the British army's latest 4x4 truck, the tender for which has recently been put out.

Inside the cab the level of trim, equipment and instrumentation clearly has been designed to suit tropical conditions. A cool air blower is standard with a heater as an option. A solar shield panel for the roof and a roof hatch are also options. The simple instrument panel is mounted in a binnacle which can be mounted easily either on the left or right of the cab. Cabs will be supplied finish-painted in white.

DRIVELINE All of the driveline components are carried over from existing Leyland export trucks, which Peter Capon says "was always the intention for these new models". Up to 13 tonnes GVW the new model's engine is the six cylinder, 5.7 litre normally aspirated 98 Series. Above this weight, the six cylinder, 6.5 litre 400 Series is used, in turbocharged form in the most powerful Comets and Super Comets. He says that although 98 Series engine production ends at Bathgate at the end of this month "arrangements have been made for the engines and replacement parts to continue to be built in small quantities for at least two years."

Capon is not yet prepared to say which engine will eventually replace the 98 Series in Comets.

Leyland is about to unveil a newly-developed Albion hub-reduction axle. The intention was that this would be fitted in 14 and 16-tonne Comets, but its launch has been delayed and for the meantime these, like all the other new trucks, use existing Albion drive axles.

The nine and 10-tonne Comets have an SR 7.16 single-reduction axle while the 11, 12 and 13-tonne models use the SR 9.20 axle. Super Comets have a bogie made up of two CHR 9.24 hub-reduction axles, with a lockable third differential between them.

All of the new models' standard gearboxes are five-speed, direct-top, synchromesh units. Nine to 13-tonne Comets are fitted with the Dana Spicer (Turner) T5-300 gearbox, while more powerful Comets and all Super Comets take the higher-torque-rated T5-400. A ZF S6-36 six-speed synchromesh gearbox is an option on all Super Comets and on 14 and 16-tonne Comets. CHASSIS

Simplicity, strength and ease of repair are the main criteria behind the design of the Comet and Super Comet chassis and suspension. Leyland's engineers are fully aware that plated weights mean little or nothing in Africa and that their trucks in service there are more likely than not to be overloaded. The development of the new models took this fully into account.

The suspension on all models is largely by shackle-ended, semi-elliptic multi-leaf springs, the number and length of leaves varying with gross weight.

Leyland's T6, two-spring bogie, as use on Constructor models, is fitted at the rear of Super Comets. No anti-roll bars are fitted to any Comet or Super Comet model. As we discovered during a drive in a more-than-fully-laden 12.12 Comet with a high centre of gravity load around Leyland's proving ground, this gives the truck the kind of roll characteristics which definitely encourage the driver to limit the speed at which he corners, and that is precisely what is intended.

Chassis frame sidemembers are made from 29.5-tonne yeild strength steel channel section with external L section flitches running from forward of the front spring rear hanger to the rear end of the frame. The crossmembers are all bolted to the sidemembers. The frame is designed not to need a body-mounting subfraine and to withstand "less than sympathetic body mounting techniques".