WAYS AND MEANS.

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

Trouble with a Rag Universal Joint.

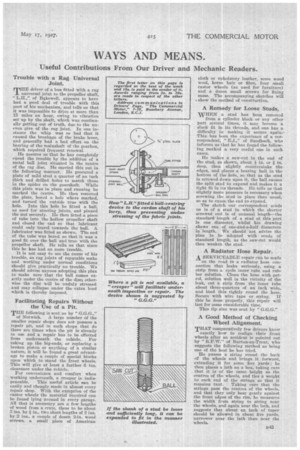

THE driver of a bus fitted with a rag universal joint to the propeller shaft, " L.H.," of Bakewell, appears to have had a good deal of trouble with this part of his mechanism, and tells us that it was impossible to drive at more than 15 miles an hour, owing to vibration set up by the shaft, which was continually getting out of truth, due to the uneven give of the rag joint. In one instance the whip was so bad that it caused the breakage of the brake lever, and generally had a bad effect on the bearing of the mainshaft of the gearbox, which required frequent renewal.

He assures us that he has completely cured the trouble by the addition of a metal ball joint situated in the centre of the rag disc. He carried this out in the following manner, lie procured a plate of mild steel a quarter of an inch thick and drilled holes to match those in the spider on the gearshaft. While this plate was in place and running he marked the centre. He then removed the plate, bored a hole where marked, and turned the outside true with the hole. Into this hole he fitted a ball, as used for steering joints, and pinned the nut securely. He then fitted a piece of tube into the hollow propeller shaft and closed the end so that lubricant could only travel towards the ball. A lubricator was fitted as shown. The end of the tube was bored so that it was a good fit over the ball and true with the propeller shaft. He tells us that since this he has had no more trouble.

It is not easy to see the eause of his trouble, as rag joints of reputable make and working under normal conditions should give practically no trouble. We should advise anyone adopting this plan to make sure that the ball comes exactly under the centre of the disc; otherwise the disc will be unduly stressed and may collapse under the extra load which is thereby imposed.

Facilitating Repairs Without the Use of a Pit.

THE following is sent us by " G.G.G.," of Norwich. A large number of the smaller repair shops does not possess a repair pit, and in such shops that do there are times when the pit is already in use and a repair has to be effected from underneath the vehicle. For taking up. the big-ends, or replacing a broken piston or anything of a similar nature, it will be found a great advantage to make a couple of special blocks upon which to stand the front wheels. This will give at least a further 6 ins. clearance under the vehicle.

For convenience and comfort when working underneath, a creeper is indis pensable. This useful article eau be easily and cheaply made in almost every repair shop. With the exception of the curter wheels the material required eau be found lying around in every garage. All that is necessary are a few lengths of wood from a crate, these to be about 3 ins, by in., two short lengths of B ins. by 2 ins., a couple of dozen 2-in, wood screws, a small piece of American cloth or upholstery leather, some wood wool, horse hair or fibre, four small castor wheels (as used for furniture) and a dozen small screws for fixing same. The accompanying sketches will show the method of construction.

A Remedy for Loose Studs,

WHEN a stud has been removed from a cylinder block or any other part several times, it may become a slack fit in its threads, and one has a difficulty in making -it secure again.This has been the experience of a correspondent, "E.J.," of Sandbach, who informs us that he has found the following method a very useful one in such cases.

He makes a saw-cut in the end of the stud, as shown, about -A in. or gin, deep, then slightly countersinks the edges, and places a bearing ball in the bottom of the hole, so that as the stud is screwed down upon it, the ball causes the split stud to expand and makes it a tight fit in its threads.' He tells us that slightly more pressure is necessary when screwing the stud in place than usual, so as to cause the end to expand.

The sketch our correspondent sends us is of a stud in which the shorter screwed end is of unusual length—the standard length of a stud at this part is one diameter, whilst his drawing shows one of onerand-a-half diameters in length. We should not advise the plan to be adopted with studs of standard length, as the saw-cut would then weaken the stud.

A Radiator Hose Repair.

A SERVICEABLE repair can be made on the road to a radiator hose connection that leaks seriously, using a strip from a cycle inner tube and rubber solution. Clean the hose with petrol, solution well in the vicinity of the leak, cut a strip from the inner tube about three-quarters of an inch wide, and bind this tightly round the hose. Secure with wire tape or string. If this be done properly, this repairwill last for some considerable time.

This tip also was sent by " G.G.G."

A Good Method of Checking Wheel Alignment.

THAT comparatively few drivers know

exactly how to realign their front wheels after an accident is pointed out by " R.F.W." of Burton-on-Trent. who suggests the following method as being one of the best he has tried,

He passes a string round the back of the wheels and brings it forward, extending it for some five yards ; he then places a lath on a box, taking care

• that it is of the sameheight as the centres of the wheels, and ties a weight to each end of the strings so that it remains taut. Taking care that the strings pass the centres of the wheels, and that they only bear gently against the front edges of the rim, he measures the width from string to string near the wheels, and again near the lath, and suggests that about an inch of taper should be allowed in about five yards, narrower near the lath than near the wheels.