HINTS ON MAINTENANCE.

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

Improving Chain Steering on Steam Wagons. Attending to Gland Packing. A Layshaft Modification on the A.E.C.

, Securing Steam-wagon Steering Chains.

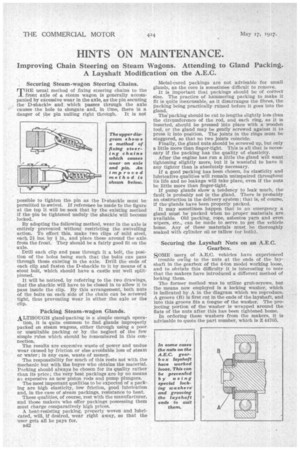

IT HE usual method of fixing steering chains to the front axle of a steam wagon is generally accompanied by excessive wear in the axle, as the pin securing the D-shackle and which passes through the axle causes the hole to elongate and, in time, there is a danger of the pin nulling right threugh. It is not possible to tighten the pin as the D-shackle mist be permitted to swivel. If reference be made to the figure at the top it will be seen that by the existing method if the pin be tightened unduly the shackle will become locked.

By adapting the following method, wear in the axle is entirely prevented without restricting the swivelling action. To effect this, make two clips of mild steel, each 2i ins, by in., arid place these around the axle from the front. They should be a fairly good fit on the axle.

Drill each clip and pass through it a bolt, the position of the holes being such that the bolts can pass through those existing in the axle. Drill the ends of each clip and fasten the D-shackle to it by means of a stout bolt, which should have a castle nut well splitpinned.

It will be noticed, by referring to the two drawings, that the shackle will have to be closed in to allow it to pass inside the clip. By this arrangement, both nuts of the bolts on each side of the chain can be screwed tight, thus preventing Wear in either the axle or the clip.

Packing Steam-wagon Glands.

ALTHOUGH gland-packing is a simple enough opera tion, it is quite common to find glands improperly packed on steam wagons, either through using a poor or unsuitable packing or by the neglect of the few simple rules which should be remembered in this connection.

The results are excessive waste of power and undue wear caused by friction or else avoidable loss of steam or water ; in any case, waste of money.

The responsibility for much of this rests not with the Mechanic but with the buyer who obtains the material. Packing should always be chosen for its quality rather than its price; the very best packings are by no means as expensive as new piston rods and pump plungers.

The most important qualities to be expected of a packing are high elasticity, low friction, good lubrication and, in the case of steam packings, resistance to heat.

These qualities, of course, rest with the manufacturer, and those makers who offer packings possessing them must charge comparatively high prices.

A heat-resisting packing, properly woven and lubridated, will, if desired, wear right away, so that the user gets all he pays for.

B42 Metal-cored packings are not advisable for small glands, as the core is sometimes difficult to remove.

It is important that packings should be of correct size. The practice of hammering packing to make it fit is quite inexcusable, as it disarranges the fibres, the packing being practically-ruined before it goes into the gland.

The' packing should be cut to lengths slightly less than the circumference of the rod, and each ring, as it is inserted, should be pressed into place with a woOden tool, or the gland may be gently screwed against it to press it into position. The joints in the rings must be staggered, so that no two joints coincide.

Finally, the gland nuts should be screwed up, but only a little more than finger-tight. This is all that is necessary if the packing has the quality of elasticity.

After the engine has run a little the gland will want' tightening slightly more, but it is wasteful to have it any tighter than is absolutely necessary.

If a good packing has been chosen, its elasticity and lubricative qualities will remain unimpaired throughout its life and no leakage will take place, even if the nuts be little more than finger-tight.

If pump glands show a tendency to leak much, the fault is probably not in the gland. There is probably an obstruction in the delivery system ; that is, of course, if the glands have been properly packed.

It may sometimes happen that in an emergency a gland must be packed when no proper materials are available. Old packing, rope, asbestos yarn and even wipers, etc., can be made to serve to get the vehicle home. Any of these materials must be thoroughly soaked with cylinder oil or tallow (or both).

Securing the Layshaft Nuts on an A.E.C.

Gearbox.

SOME users of A.E.C. vehicles have experienced

trouble owri-ig to the nuts at the ends of the layshaft in the gearbox of the 4-ton model working loose, and to obviate this difficulty it is interesting to note that the makers have introduced a different method of locking them.

The former method was to utilize grub-screws, but the means now employed is a locking washer, which is indicated by A in the diagram which we reproduce. A groove (B) is first cut in the ends of the layshaft, and into this groove fits a tongue of the washer. The projecting portion of the washer is wrapped around the flats of the nuts after this has been tightened home.

In ordering these washers from the makers, it is advisable to quote the part number, which is Z 44705.