FORD VAN POINTERS.

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

By R. T. Nicholson (Author of "The Book of the Ford").

WE MOTORISTS all have to use tools at times —worse luck! It is riot too much to say that most of us misuse them. Misused teols become instruments of torture. ,

Of all. misused tools, the nut-tightening tool stands easily first. There are many forms of nut-tighteners —pincers, adjustable wrenches, -and fixed spanners being the chief.

348.—Ford Tools: Their Uses and Abuses.

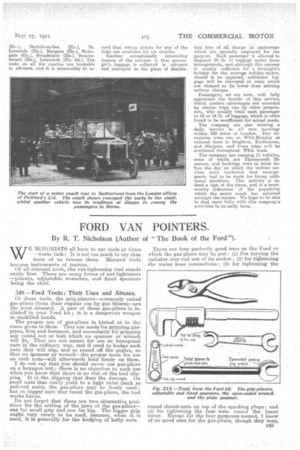

Ot these tools, the grip-pincers—commonIy called gas-pliers (from their regular use by gas fitters)—are the most misused. A pair of these gas-plie-rs is included. in your Ford kit ; it is a dangerous weapon in unskilled hands.• The proper use of gas-pliers is hinted at in the name given to them. They are made for gripping gaspipes, first and foremost, and' secondarily for gripping any round nut or bolt which no spanner or wrench will fit. They are not meant for use on hexagonal nuts in the ordinary way, and if used to budge such nuts they will slip, and so round, off the angles, so that no spanner or wrench—the proper tools for use on such nuts—will afterwards hold firmly on them. I do not say that you should never use gas-pliers on a hexagon nut ; there is no abjection to such use when you know that there is no risk of the tool slipping. It is the slipping that does the damage. On small nuts that easily yield to a light twist .(such as pull-rod nuts), the gas-pliers may be freely used; but on bigger nuts that resist the gas-pliers, the too works havoc.

Do not forget that there are two alternative positions for the setting of the jaws of the gas-pliersone for small grip and one for big. The bigger grip ought very rarely -to be used, because, wheit is used, it is generally for the budging of hefty nuts.

There are four perfectly good uses on the Ford to which the, gas-pliers may be, put: (i) For turning the radiator stay-rod out of its socket ; (2) for tightening the water hose connections ; (3) for tightening the round thumb-nuts on top of the sparking plugs; and (4) for tightening the four nuts round the timer cover. Except for the four purposes named, I know of no good uses for the gas-pliers, though they may, of course be used a-s ordinary pincers—far pulling nails.or drawing split-pins.

One or two cautions, however, as to the use of the gas-pliers in two of the four cases mentioned: In tightening any electrical nuts other than those mentoned, never use the gas-pliers ; if you do, you are likely to smash something. In tightening the water connection clips' do not tighten more than is necessa.ry to prevent drip. Over-tightening-means cutting into the rubber and perishing the haws.

The Adjustable Spanner.

An adjustable spanner, though a less deadly weapon than the gas-pliers, can easily become an instrtunent of torture in careless hands. If it is a had tool in itself—if the movable jaw is " sloppy " or out of parallel with the fixed jaw—it can do untold harm ; and if, further, its user is slovenly as to its fit on a nut or bolt, it can round off the angles nearly as well —or badly—as the gas-pliers will do. The jaws must be tight on their work ; they must not. give when pressure is applied. The odds are that, however carefully tightened on first application, the setting of the jaws will shift in repeated applications in turning a hefty nut, so that, even if they bite well on first application, they will slip a bit on the second, and get positively sloppy on the third, by gradual loosening of the grip adjustment. The set of the jaw ought to be tightened at each shifting of the tool, and not made once and for all for the nut. At best, however, any adjustable spanner is a broken reed, especially when it is a question of turning a big, obstinate nut or a sparking plug. In such cases the spanner ought to he a fixed one.

The Fixed Spanner.

Always use a fixed spanner when passible. Of fixed spanners there are various kinds. ' All-round " spanners—spanners, that is, which completely surround the nut (or bolt-head) to be budged—are the best of the lot, if set squarely in position. The hubcap wrench in the Ford kit is a good example. Plate spanners—spanners consisting of a flat plate in which one or more hexagonal holes are cut—are excellent for smaller nuts. Such spanners are often to be found in a bicycle outfit. The best among such plate spanners are those with a. hole at one end, or at two points, only. The many-holed plate spanner is generally an awkward tool to work with. The two-ended "all-round" spanner is often heftily made, and equal to budging any nut it will fit.

Another good form of " all-round "-spanner is the box-spanner with a " tommy." I believe there ought to be a set of such spanners in every tool kit. They should be strongly made, or their scekets will burst under pressures and they are then useless.

Socket wrenches, like the kit tool supplied for use on cylinder head bolts, are good for particular purposes. Their sockets rarely burst, though they sometimes get loose on their bars, and their use is then risky. There is another danger about them—they are so hefty that if too much pressure is put behind them, something has to " go.' That " something" is often a cylinder head bott.

In point of fact, those cylinder head bolts do not call for brutal tightening if the cylinder head gasket is in good condition and well packed with soap, goldsize, seceotine, or red lead and boiled oil. Unless the gasket is good and properly packed, no amount of tightening of the bolts will give. you a waterproof joint.

And while I am on this point, let me say that in tightening a group or series of nuts like those round the cylinder head or the lower transmission cover, you ought not to tighten any one full up first. What you should do is -to get them all finger-tight, and then give each a slight spanner turn—an equal turn to each, working preferably on opposite nuts some distance apart. Unless you do this, you strain things badly.

C24

The Open-ended Wrench.

The fixed, open-ended wrench is quite a good tool if strong enough for the work to which it is put. The mistake lies in using a light spanner for heavy work. For instance, one end of the carburetter spanner is very slight, and. can easily be made to -" gape ". if used on a nut that strongly resists it. That spanner should be kept strictly for use on the carburetter, where it has te do only light work. There is one big, open-ended wrench in the Ford kit—that meant for use on the sparking plugs. 'It is nicely curved so as to give-a good grip on the plugs, but only if you have plugs that it will fit. It fits perfectly the standard plugs sent out with the Ford, and usually fits any plugs specially made for the Ford ; but you must not take it for granted that it will do so in the latter case. Buy plugs to fit this spanner, and you will be saved much trouble when it becomes a, question of budging a plug ; for plugs will bind, and unless their spanner really fits, the budging thereof may become a really dangerous job. If the grip gives when you are putting your weight on to the spanner and your hand flies away against the radiator or other metal, you can get a very nasty gash.

Tightening Battery Clamps.

On the new model, the battery clamps should be lightly tightened with a spanner—I mean the clamps from which the two big cables run from the battery.

Unless you work carefully, you are likely to shortcircuit the battery when using a spanner on these clamps—by touching at the same time a positive and a negative terminal with the tool. This is very bad for the battery. You can make sure of not doing it if you. wrap paper round your spanner, covering everything but its " business end,". or lay a sound sheet of paper over every part of the battery except the clamp on which you are going to work. Do this last in such a way that your tool can touch no metal except the clamp. A more effective " shield" fer such a purpose is a strip of rubber cut from an old inner tube.

How to Treat the Jack.

Keep this well lubricated as regards working parts. The jack is generally neglected, and it is such hard work lifting the van with a rusty jack.

Keeping the Inflator in Condition.

Smear the barrel internally with a ring of vaseline or engine oil occasionally, so that the leather of the plunger will not get dry. Occasionally wash out the barrel with petrol. Do not wash the leather plunger, or you will 4117 it out ; do not wash the connecting tube, or you will perish it. Remove both before flushing. See that the plunger goes back with its hollow side down and that the whole ring of leather enters hollow side down, not with one little bit tucked back ; this means "humouring."

The Uses of a Split-pin Extractor.

Special tools are sold for extracting obstinate split. pins ; and split-pins can be obstinate, as we all know. A good tool for this purpose can be made with a strong button-hook. It is usually necessary to file its point down a bit, so that it will enter the eye of the split pin, and to give acertain amount of set to the metal behind the hook, so that you may get good purchase when the point is entered.

{I regret that errors have occurred during the past few weeks in the numbering of the. Figure6 accompanying my contributions. I have correctly numbered the illustration appearing on the previous page, so that those who are filing "Ford Van Pointers" (a commendable practice, may I suggest?) will bo able to correct the errors in the issues of April 26th and May 10th.—R.T.N.]