Mercedes-Benz presents the LP's successors

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Developed over five years at a cost of over £150m, the new mediumweight range will, in the opinion of Bill Brock, substantially improve MB's UK market share in 7.5 to 16-tonne sector

TWO DAYS ago 600 vehicles were dispatched with German precision from Mercedes-Benz's Worth factory to the company's branches and dealers throughout the Continent.

Today Mercedes-Benz presents a new range of mediumweight commercial vehicles in mainland Europe. In Britain we will have to wait a few more months until July for right-handdrive models to succeed the LP range which has enjoyed a production run of more than 20,000 units in the past 19 years.

Initially the weight range will encompass models from 6.5 to 11 tonnes but it will be extended later to include models up to 14 tonnes.

The 709-1120 rigid range, comprising seven basic models, has taken seven years to develop to the production stage and owes nothing, either in mechanical or esthetic design, to its forerunners.

For Britain the choice will be restricted to less than the full range. 809, 814 and 1114 models are designated to replace 809, 813 and 1113 LP models, Additionally for the rest of Europe there will be lightweight tractive units equipped with short or long tilt cabs for operation between 18 and 24 tonnes gvw.

Compared to the existing LP range the new vehicles are marginally shorter with platform lengths of 4.2m to 8.2m (13ft 91n to 26ft 11in); they are wider, measuring 2.3m (7ft 61/2in), so that overall payload area is increased to accommodate one extra DIN pallet or two additional Euro pallets.

The wheelbase, with the front axle moved towards the rear of the chassis, has been shortened to improve manoevrability and provide for an evenly distributed load at maximum weight. Lowprofile tyres contribute to a low platform height, which for the 7820 measures just 1.11m (44in).

At the design stage, unladen weight was also a major consideration. The box-type chassis frame, flat topped over the body section and fish-belly shaped, is tailored in height and side-member thickness to suit the various operational weights and wheel base dimensions. Saving more weight, twin parabolic springs are included on the front-axle, while the rear-axle suspension comprises a short parabolic leaf supporting the two main leaves fitted above.

Performance of the spring pack is unimpaired through fric tion as all dynamic forces are transmitted through rubber separator damping pads. Improved damping increases ride comfort and the whole spring assembly is maintenance free.

Drawing from both the light van range and heavier truck models, the cab is styled to complement other modern Mercedes-Benz vehicles. Although large at this weight, a high aerodynamic efficiency is claimed for the cab but M-B was unwilling to be committed to a specific Cd value.

The windscreen is inclined and edges and corners have large radii. With rain runnels constructed to be integral with the windscreen pillars, a smooth air flow is assured. An air-shield has been specially developed to be mounted on this cab where body equipment is a box or similar type.

The standard version is suplimented by a longer cab, some 650mm (251/2in) larger giving sufficient room for either one or two single bunks.

Maximum tilt is 55 degrees and the manual effort required to lift the short cab is only 13kg (281/2 lb).

A hydraulic system is supplied with the long-distance cab.

Sound insulation in and around the engine compartment adds more than 35kg (77 lb) to the unladen weight, but individual ready-for-the-road weights have been contained to within plus or minus 40kg (88 lb) of the models they replace.

A range of four engines giving high torque characteristics was developed for this range with the aim to improve performance and fuel economy, though equal consideration was given to life and reliability. The least powerful is the OM 364, a four-cylinder naturally aspirated unit, with a capacity of 3,972cc, power output of 66kW (88bhp) at 2,800rpm and torque of 266Nm (196 lbft) at 1,400rpm.

There is a naturally aspirated version of the six-cylinder 5.968litre 0M366 rated at 100kW (1 34 bhp) at 2,8 0Orpm and 266Nm (196 lbft) on 0M366N turbocharged units developing 125kW (170bhp) at 2,600rpm and 560Nm (413 lbft) and an OM 366LA turbocharged and intercooled engine producing 148kW (198bhp) at 2,600 and torque of 640Nm (472 lbft) also at 1,40Orpm.

For the most pwerful OM 36 6LA unit, the minimum specific fuel consumption on the full load curve has been measured as 198g/kWh rising to just 223g/kWh at nominal engine speed.

M-B says that factors contri buting to this performance are the design of the intake and exhaust systems (in some instances twin pipes are used) and optimisation of combustion with regards to swirl, valve timing and injection rate. A more powerful injection pump has been developed for use in the turbocharged engines.

Special attention was paid to the rigidity of the block and cooling of the head where coolant is routed directly to hot spots such as the valve land and the nozzles.

In the naturally-aspirated units the pistons run directly in the crankcase while turbocharged engines have dry cylinder linings.

While piston design differs in the different engines with porous-chromed modular iron rings fitted in naturally aspirated units and molybdenum coated steel rings in turbocharged units.

The two naturally-aspirated four and six-cylinder engines are matched to the Daimler-Benz five-speed synchromesh G2 and G3 transmissions. New G4/G5 transmissions are specified to match the more powerful sixcylinder units. Six-speed transmissions can be equipped with a splitter group providing 12 gear steps.

Brake equipment diverts from normal practice at these weights. Pneumatic equipment was developed for use throughout the range. Drum brakes with a diameter of 304mm (11.96in) are fitted with 135mm (5.3in) linings up to nine tonne gvw and larger diameter 160mm (6.3in) drums and wider 360mm (14.2in) linings are used up to 11 tonnes gvw.

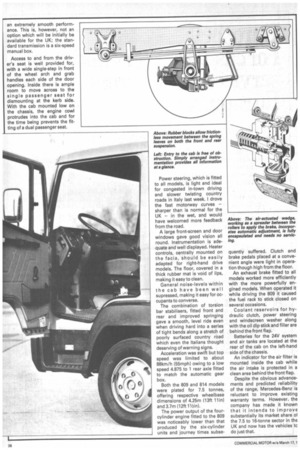

Mercedes is the first vehicle manufacturer to use a wedge-actuated Simplex brake with pivoted brake shoes. These, it claims, give constant friction behaviour and fast response. Integral automatic adjusters makes them almost maintenance-free.

With the introduction of the air brakes at these lower weights, Mercedes is now able to offer its ABS anti-locking brake system throughout its complete vehicle range. Slip joints employed throughout the air system are said to be leak proof.

Before I had the chance to drive some of the new models Mercedes had already completed more than 5.5 million km in road tests and customer proving. Our test route, situated just to the south of Rome, measured 40km and contained a mixture of motorway, twisting main road and a hilly country section. From the 17 vehicles I chose left-handdrive versions of the models destined for the UK.

The 1114 at 11 tonnes has a wheelbase of 3.7m (12ft 11/21n).

From the outside, rounded edges make this large cab seem smaller than its true dimensions. Bumper airdam steps, mudguards and a large front-maintenance flap/grille are made of sturdy plastic which will not corrode but will be able to withstand the occasional minor knock without damage; the vulnerable bolted corner panels can be easily replaced.

The naturally-aspirated 100kW (136bhp) six-cylinder engine drove through to a W4B035 automatic gearbox, which gave an extremely smooth performance. This is, however, not an option which will be initially be available for the UK; the standard transmission is a six-speed manual box.

Access to and from the driver's seat is well provided for, with a wide single-step in front of the wheel arch and grab handles each side of the door opening. Inside there is ample room to move across to the single passenger seat for dismounting at the kerb side. With the cab mounted low on the chassis, the engine cowl protrudes into the cab and for the time being prevents the fitting of a dual passenger seat. Power steering, which is fitted to all models, is light and ideal for congested in-town driving and slower twisting country roads in Italy last week. I drove the fast motorway curves — sharper than is normal for the UK — in the wet, and would have welcomed more feedback from the road.

A large front-screen and door windows gave good vision all round. Instrumentation is adequate and well displayed. Heater controls, centrally mounted on the facia, should be easily adapted for right-hand drive models. The floor, covered in a thick rubber mat is void of lips, making it easy to clean.

General noise-levels within the cab have been well supressed, making it easy for occupants to converse.

The combination of torsion bar stabilisers, fitted front and rear and improved springing gave a smooth, level ride even when driving hard into a series of tight bends along a stretch of poorly surfaced country road which even the Italians thought deserving of warning signs.

Acceleration was swift but top speed was limited to about 88km/h (55mph) owing to a low speed 4.875 to 1 rear axle fitted to match the automatic gear box.

Both the 809 and 814 models were plated for 7.5 tonnes, offering respective wheelbase dimensions of 4.25m (13ft 11in) and 3.7m (12ft 11/2in).

The power output of the fourcylinder engine fitted to the 809 was noticeably lower than that produced by the six-cylinder units and journey times subse quently suffered. Clutch and brake pedals placed at a convenient angle were light in operation though high from the floor.

An exhaust brake fitted to all models worked more efficiently with the more powerfully engined models. When operated it while driving the 809 it caused the fuel rack to stick closed on several occasions.

Coolant reservoirs for hydraulic clutch, power steering and windscreen washer along with the oil dip stick and filler are behind the front flap.

Batteries for the 24V system and air tanks are located at the rear of the cab on the left-hand side of the chassis.

An indicator for the air filter is mounted inside the cab while the air intake is protected in a clean area behind the front flap.

Despite the obvious advancements and predicted reliability of the range, Mercedes-Benz is reluctant to improve existing warranty terms. However, the company has made it known that it intends to improve substantially its market share oi the 7.5 to 16-tonne sector in the UK and now has the vehicles tc do just that.