PARKING WITHOUT PULLING

Page 74

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

JUST over a year ago ERF Ltd. started work on a system of spring-powered braking to dispense with the need for a mechanically applied and held band-operated parking brake. At that time no such system had approval from the Ministry of Transport and it was necessary that vehicles should be submitted to the Ministry testing establishment at Crowthorne, Berkshire for evaluation. This was done and the company now has a special dispensation to build a number of vehicles of each of the types submitted. Recently Commercial Motor were able to test a 30-ton g.v.w. artic so equipped.

The biggest single advantage claimed for the new system is that should there be a failure in the air-pressure circuits of a vehicle incorporating the ERF system, what is vir

tually the hand parking-brake immediately comes into operation. The vehicle tested was a 64 CU180 tractive unit hauling an ERF tandem-axle semi-trailer, the whole outfit being plated for operation at 30 tons g.v.w.

The most obvious point when driving a vehicle with the new system is the absence of a handbrake lever, which has, of course, been a permanent item of vehicle equipment ever since the days of the horse and cart. In recent years the increasing operating weights of road-going vehicles has made the operation of handbrake systems both clumsy and largely ineffectual; in fact, one or two vehicles have been produced for maximum g.t.w. with purely mechanical handbrake systems which have been nothing more than an apology to legal requirements.

It has not been unusual to find units corn

pletely incapable of producing any reading at all on the Tapley meter when tests have been carried out. More frequently it has been the case that handbrakes have failed completely when tested for holding capabilities on severe gradients.

Whilst some companies—ERF included —have produced systems in which the handbrake has been air-assisted, this has tended to complicate even further what is already a complex system, and has moreover, added yet another air circuit in which failure can occur. The spring-powered handbrake system is mechanical and is simply applied to all wheels, including those of steering-axles. As I said earlier, it fails to the safe, or applied condition.

When testing the 30-ton outfit recently I found myself at one stage in the unenviable position of being in a country lane on a gradient that the tractive unit refused to climb. Although this was not a test that I had intended to carry out it proved in no uncertain terms that the spring brakes are extremely efficient. Imagine the same conditions when one is relying on an adequate supply of air from the service braking system and, should this not be forthcoming, the totally inadequate holding power of a purely mechanical handbrake system which simply cannot—when applied to one axle only—be made to hold 30 tons on a I in 5 gradient.

Drivers often find that an air-pressure system which works extremely well in normal conditions can quickly be exhausted by continuous maximum-pressure pedal applications when the engine is running slowly, The procedure then is to hold the vehicle as best as one can in neutral gear or with the clutch out until sufficient air pressure has been restored to the reservoir.

As no man is endowed with more than two feet and two hands it is often necessary for a vehicle to be backed into a bank or kerb in order to prevent its running away. Obviously, if the reason for backing down a steep gradient is because one has failed to complete the climb in the first place, once in this latter position of either laying on to a bank or kerb then, without outside assistance, it is often impossible for the vehicle to be moved.

No worries My experience with the spring brakes proved beyond any doubt that one has no worries whatsoever in such conditions because the very worst that can happen is that all the tractive unit wheels lock on and the vehicle is held safely at rest. The one problem that did arise was that with the brakes applied to the front axle, movement of the steering became almost impossible whilst holding on the gradient. I would con

skier that for such high gross vehicle weights as 30 and 32 tons, power-steering is virtually essential.

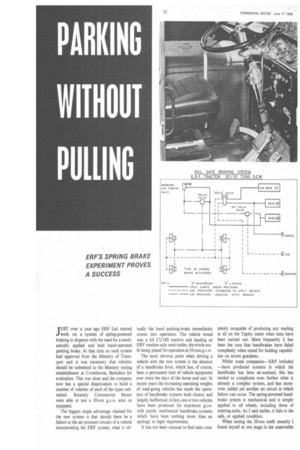

All the models produced by ERF which are plated -for operation at the g.v.w. permitted under the 1964 amendments to the C. and U. Regulations are equipped with the new braking system, The standard ERF air circuits which incorporate a dual brakevalve fed from two independent reservoirs giving separate circuits to front and rear axles is, in itself, an emergency system inasmuch as that complete failure of either circuit leaves the other intact and fully operational.

Air holds spring brakes off

Air pressure utilized for holding the spring brakes in the off position is stored in an independent reservoir and controlled by a hand-reactor valve which has been specially developed for use with spring brakes. Incorporated in the reactor-valve lever is a locking device controlled by a springloaded button, and this comes into use when the lever is placed in the fully applied position. In this condition air pressure loaded against the springs when in the running position is destroyed to atmosphere.

Spring brake application can be fully graduated by this system in just the same way as when such a valve is used to control trailer axle brakes; it is, of course, working in the opposite direction.

Four-wheelers have spring brakes applied on the rear wheels only, while six-wheelers have the system applied to all wheels on the rear bogie, as do 24and 26-ton-gross eight-wheelers. Tractive units are equipped with a hand reactor valve piped in the normal manner to the third-line on the semitrailer and a second relay valve incorporated in the third-line, but operating inverted controls the destruction of air pressure in the spring-brake reservoirs. This gives a high percentage of braking effort on all wheels.

Part of the test carried out by COMMERCIAL MOTOR entailed a controlled descent almost from the top of Mow Cop. It was near the top of this notorious hill that we ran out of power and although a lot of effort was expended I did at last manage to turn the outfit round and face down the hill. Cutting out the trailer brakes, the vehicle was allowed to run down the 1 in 5 gradient on the spring brakes only and I found that it was possible to bring the whole outfit to rest on this gradient using only the spring brakes. On the third and last occasion that I tried this I must admit that the vehicle only just came to a rest and would have needed little persuasion to send it on its way to the bottom.

Thinking back to other tests carried out on this hill where vehicles have been fitted with the old-fashioned ratchet handbrake I can remember too clearly the amount of effort and, although not panic action, the extremely quick action that was needed when stopping and starting. This ERF system eliminates the need for any effort by the driver and is extremely efficient in its control of the outfit.

On the road the spring brakes proved to be slightly above the efficiency required by the MoT for handbrakes in that from 20 m.p.h. figures of 26 per cent were recorded on the Tapley meter. However, when the Tapley was left free and a stop was completed from 25 m.p.h., a steady reading of 21 per cent was recorded.

Service brake figures were very disappointing, with results below the requirements of the Ministry of Transport being returned on every stop made.

Obviously all was not well with the system. So the vehicle was taken back to ERF for attention and arrangements made for further tests to be carried out later. A report of the findings will be published in COMMERCIAL MOTOR when these tests have been completed.