Dorman to make vehicle engines again

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

BY R. D. CATER, A ni inst e E

TN the early 1930s Dorman Ricardo engines, made by W. H. Dorman and Co. Ltd., Stafford, were frequently fitted into road transport vehicles and earned themselves a reputation for being long-lived and reliable. Since the arrival on the transport scene of the mass-produced lightweight diesel engine, Dorman has restricted its activities to the heavier and more exacting fields of marine, industrial and civil engineering equipment where the company has, over recent years, developed some very big power units that run at startingly high speeds.

The best example of the degree of development reached by Dorman is a 930 b.h.p. V12 which currently is being installed in a dump truck in the USA which carries a 105-ton payload and runs at 150 tons gross vehicle weight. The engine has a maximum of 1,950 r.p.m. and a number of units have been running trouble free for a considerable time.

In recent months Dorman has recognized that its air-cooled DA engines have a potential in road-going vehicles and much development has taken place to overcome the critical top piston-ring temperatures that create such disastrous results in many air-cooled engines.

Frank Brooks, formerly of Gardner Engines and ERF Ltd., and now chief engineer of Dorman Diesels, is extremely well versed with the requirements of automotive diesel engine application and has been carrying out numerous experiments in the design of pistons used in the engine in order to disperse excess heat from the piston crown into the walls and thereafter through the cylinder walls and away through finning.

This last mentioned point is also receiving considerable attention and I was told by Mr. Brooks that three extra fins on a barrel had reduced the cylinder temperature by up to 10°C.

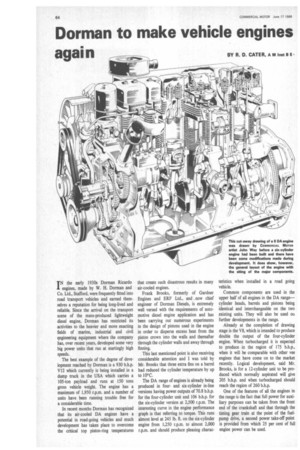

The DA range of engines is already being produced in fourand six-cylinder in-line versions having power outputs of 70.8 b.h.p. for the four-cylinder unit and 106 b.h.p. for the six-cylinder version at 2,500 r.p.m. The interesting curve in the engine performance graph is that referring to torque. This runs almost level at 245 lb. ft. on the six-cylinder engine from 1,250 r.p.m. to almost 2,000 r.p.m. and should produce pleasing charac teristics when installed in a road going vehicle.

Common components are used in the upper half of all engines in the DA range— cylinder heads, barrels and pistons being identical and interchangeable on the two existing units. They will also be used on further developments in the range.

Already at the completion of drawing stage is the V8, which is intended to produce double the output of the four-cylinder engine. When turbocharged it is expected to produce in the region of 175 b.h.p., when it will be comparable with other vee engines that have come on to the market recently. Logical development, said Mr. Brooks, is for a I2-cylinder unit to be produced which normally aspirated will give 205 b.h.p. and when turbocharged should reach the region of 260 b.h.p.

One of the features of all the engines in the range is the fact that full power for auxiliary purposes can be taken from the front end of the crankshaft and that through the timing gear train at the point of the fuelpump drive, a second power take-off point is provided from which 25 per cent of full engine power can be used. Having a bore of 105 mm. (4.134 in.) and a stroke of 120 mm. (4.724 in.) the fourcylinder engine has a cubic capacity of 4.15 litres (253 cu.in.). The six cylinder unit has the same bore and stroke and a capacity of 6.23 litres (380 cu.in.). Bigger engines will have the same bore and stroke and therefore will be multiples of the smaller units.

Common crankpins are used for opposing cylinders in the vee designs and in all engines there are main bearings between each crankpin. Bearing dimensions are generous with the mains being 3 in. in diameter, whilst bigend journals are 2.5 in. All bearings are pre-bored and steel-backed, reticular tin, aluminium-lined shells are fitted. Small-end bearings are 1.5 in. in diameter and these have a steel-backed, copper-lead lined bush.

Cylinder barrels are cast in close-grained iron and the bores are hone finished. Cylinder heads are cast in aluminium alloy and, like the cylinder barrel, are in single units. Head and barrel are secured to the crankcase by four long, high-tensile-steel studs, a system which allows any individual cylinder and piston assembly to be removed without disturbing those adjacent to it.

A rotary-type pressure pump circulates oil from the wet sump to crankshaft bearings • and camshaft bearings and also the rocker gear. Mounted on the front of the timing case the pump is quickly accessible in the event of it needing servicing or changing. Oil passing through the pressure relief valve is directed to the hellical timing gears, ensuring ample lubrication of these at all times. The main lubrication system operates at 40 to 50 p.s.i.

Currently, fuel-injection equipment includes CAV DPA distributor-type fuel pump and the injectors are so positioned in the cylinder heads as to be in the main cooling air stream.

A small-diameter co-axial fan provides cooling air via a carefully designed cowling to ensure equal cooling at all points around each cylinder assembly, and an oil cooler is incorporated in the cowling.

It is highly likely that the four-, sixand eight-cylinder DA engines will be offered as replacement units for a number of mediumweight goods chassis, and Dorman Diesels are in the process of carrying out conversions to vehicles in their own fleet to enable further development work to be carried out.

W. H. Dorman is now a member of English Electric Diesel Engines Ltd., known as Dorman Diesels, Stafford.