'ficlent Irons Out the Bumps

Page 47

Page 46

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

A Chassis Developed in Great Britain 'Specifically for _Operationon Unsealed Roads Overseas Shows its Paces on Bagshot Heath ; Suspension and Steering Modifications Prove Their Worth By John F. Moon,

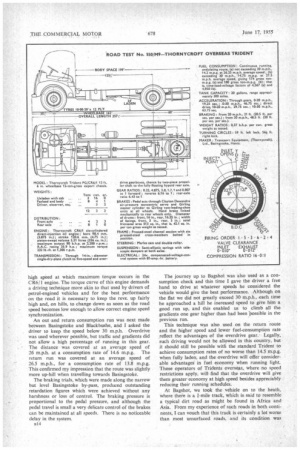

DESIGNED specifically for operation over the worst roads to be found anywhere overseas, the latest Thorn ycroft Overseas Trident, model PG 'CR6/I, differs principally from the home model (RG) in respect of suspension, tyres and braking equipment Several fast circuits of a rough track on Bagshot Heath convinced me of the excellence of the new suspension, and for road working the Trident gives a swift

and economical performance, coupled with braking of an exceptionally high order.

The CR6:1 engine, which powers the Trident range, was uprated last year to give a maximum power output of 90 b.h.p. This was done by raising its governed maximum speed and slightly altering the inlet valves and springs. Available as an optional extra is the over'drive which converts the normal five-speed gearbox into a six-speed unit. This gear is a conventional constant

mesh assembly which bolts directly on to the back face of the main gearbo.it.

Smoothness of transmission over rough country is a valuable asset and this has been accomplished in the Trident by the use of a Layrub flexible centre-plate in the clutch unit and a Layrub joint in the transmission line directly behind the gearbox.

The all-important feature of the vehicle lies in its suspension, which has received very thorough trial and development, and brings the chassis almost into the cross-country category despite its conventional chassis layout. The wheelbase' remains the same, hut both front and rear springs have been increased in length by 6 in. and 4 in. respectively and 7-in.-stroke telescopic dampers are fitted to both axles. Deep bump 1312 rubbers have been incorporated more as a contributory factor in the suspension than as an overload safeguard.

In countries where British tyre ratings

are accepted, the standard tyre equipment foc 12-ton-gross running is 9.00 by 20 in., but many areas overseas demand a greater safety margin which necessitates 10.00 by 20 in. equipment, and to accommodate these larger tyres slight alterations have been made to the front and rear axles_

Without altering the steering-box ratio, the steering geometry has been slightly changed by shortening the drop arm and, here again, the effect of this arrangement is demonstrated to the full over rough country, perfect control of the vehicle without harsh wheel-kicking being maintained at high speeds_ Brakes are a particularly vulnerable feature of vehicles which are operated "in the rough," especially when native drivers are employed, as their main driving technique dbnsists of the highest possible gear and the maximum possible braking. The Trident's brakes should cause no worries, however. A Clayton Dewandre diaphragm-type air-pressure servo is used in conjunction with the Girling hydraulic system and modified operating wedges give a greater shoe lift, this being possible by virtue of the increased power available at the master cylinder. The compressor is driven in tandem with the fuel injection pump and replaces the exhauster on RG models.

It was decided to assess the hill-climbing, capabilities of the Trident first and Farleigh Hill was the obvious choice for this task. This hill, which is 1.4 miles long, has an average gradient of I in 27 with the maximum section of 1 in 8.4 occurring about half-way up. The radiator temperature at the bottom of the hill gave a reading of 113° F., and a fast climb was made at an

average speed of 16.8 m.p.h., the steep section requiring the use of second gear, at which point the speed fell to 6 m.p.h. The temperature rise was 8° F. at an ambient temperature of 54° F.

The descent was made with overdrive engaged and the speed was kept below 25 m.p.h. by use of the brakes. At the bottom of the hill an emergency stop from 20 m.p.h. produced a Tapley meter reading of 72i per ern. The vehicle was turned round in Cliddesden and a second climb made. The time taken was slightly longer on the second occasion, the average speed being 16.0 m.p.h., and once again the temperature rise was only 8° F. Allowing for the low ambient temperature and the fact that there was a cowl between the fan and the radiator block, the small rises obtained during these climbs are an indication that engine cooling is suitable for hilly working and ambient temperatures well above 100° F.

A braking descent was made as before, and this time the drums became warm enough to create a strong smell of hot brake facings. A "65 per cent." stop was made from 20 m.p.h., and later in the test, when the drums were quite cold, a similar stop was made from 20 m.p.h. and produced a Tapley meter reading of 77 per cent.

A return was made to the 1-in-8.4 section and here the vehicle was stopped. The short hand-brake lever required a good pull to get it far enough back to hold the chassis. Even so, there were two notches in hand and it was not necessary to apply the foot brake to either pull on the hand brake or to release it. An extremely smooth start was made in second gear with no transmission judder and without excessive use of the throttle.

Acceleration tests were carried out along the London road and the direct-drive tests reflected the relatively a13 high speed at which maximum torque occurs in the CR6/1 engine. The torque curve of this engine demands a driving technique more akin to that used by drivers of petrol-enginecl vehicles and for the best performance on the road it is necessary to keep the revs. up fairly high and, on hills, to change down as soon as the road speed becomes low enough to allow correct engine speed synchronization.

An out and return consumption run was next made between Basingstoke and Black bushe, and I asked the driver to keep the speed below 30 m.p.h. Overdrive was used wherever possible, but traffic and gradients did not allow a high percentage of running in this gear. The distance was covered at an average speed of 26 m.p.h. at a consumption rate of 14.6 m.p.g. The return run was covered at an average speed of 26.5 m.p.h., for a consumption rate of 13.8 m.p.g. This confirmed my impression that the route was slightly more up-hill when travelling towards Basingstoke.

The braking trials, which were made along the narrow but level Basingstoke by-pass, produced outstanding retardation figures which were achieved without any harshness or loss of control. The braking pressure is proportional to the pedal pressure, and although the pedal travel is small a very delicate control of the brakes can be maintained at all speeds. There is no noticeable delay in the system.

a14 The journey up to Bagshot was also used as a consumption check and this time I gave the driver a free hand to drive at whatever speeds he considered the vehicle would give the best performance. Although on the flat we did not greatly exceed 30 m.p.h., each time he approached a hill he inareased speed to give him a good run up, and this enabled us to climb all the gradients one gear higher than had been 'possible in the previous run.

This technique was also used on the return route and the higher speed and lower fuel-consumption rate reflect the advantages of the overdrive gear. • Legally, such driving would not be allowed in this country, but it should still be possible with the standard Trident to achieve consumption rates of no worse than 14.5 m.p.g. when fully laden-, and the overdrive will offer considerable advantages in fuel economy when running light. Those operators of Tridents overseas, where no speed restrictions apply, will find that the overdrive will give them greater economy at high speed besides appreciably reducing their running schedules.

At Bagshot, we took the vehicle on to the heath, where there is a 2-mile track, which is said to resemble a typical dirt road as might be found in Africa and Asia. From my experience of such roads in both continents, I can vouch that this track is certainly a lot worse than most unsurfaced roads, and its condition was aggravated by recent heavy rains and by severe rutting caused by cross-country military vehicles.

A cautious trial circuit of the course was made to see if there was any risk of the vehicle becoming irrecoverably bogged. The back half of the course was not as bad as the first half, being slightly higher and therefore not so flooded, but it contained several corrugated sections which closely resembled severe washboarding.

I then drove the Trident around this track several times, progressively increasing speed on each run. On the bad sections, with deep potholes and soft mud, fourth gear was necessary and speed was reduced to 10 m.p.h., but on the drier corrugated part it was possible to use fifth gear and at times to take the speed as high as 25 m.p.h. At these speeds, on both parts of the course, tIlp performance was amazing for such a conventional-looking vehicle.

There was no direct kicking to be felt at the wheel, merely a slow, easily corrected pull when a front wheel passed over a particularly sievere bump or pothole. Even in quite thick mud it was possible to steer the vehicle accurately.

Over the corrugations the suspension worked overtime, the bump .rubbers combining with the telescopic dampers to absorb all the shocks, and the chassis rode smoothly over the worst of it. After these trial circuits, I topped up the test tank and went round the course eight times at an average speed of 13 m.p.h. The six miles were covered at the expense of 6.8 pt. of fuel, corresponding to a consumption rate of 7.06 m.p.g.

A Thoroughbred It would be rarely that the consumption rate would rise to this figure on normal overseas dirt roads, because the exaggerated conditions at Bagshot made the use of the indirect ratios imperative. With most bad 'roads it is generally accepted that the higher the speed the smoother the ride, and this would allow a continuous use of direct ratio, if not even overdrive, thereby. improving the consumption rate and the average speed. However, the course did satisfy me as to the efficiency of the Trident's suspension which, in my opinion, is well up to the standard normally associated with thoroughbred cross-country vehicles.

The Trident's handling on the road was also above criticism. The universally adjustable driving seat and telescopic steering column allow for a wide variety of driving positions to suit all sizes of driver, and the generous window area gives good visibility to front and side, although I would have welcomed corner lights in the rear panels to improve the all-round visibility. The steering was pleasantly light, even when taking sharp corners at full lock, and there was a useful self-centring action which was at no times fierce.

Once the geography of the gear change had been mentally mapped out, quick and silent changes were possible and the short gear-lever travel and light clutch operation also assisted in quick gear changing.

For my maintenance check I decided to carry out the daily and weekly tasks which are recommended by the makers in their comprehensive driver's instruction book and equally thorough maintenance manual. An extremely good tool kit is provided with the Trident, including such tools as two pump guns, one for grease and one for oil, oil can, hammer, pliers, circlip removal tools and a spare injector nozzle.

The recommended daily routine consists of checking the radiator water level and topping up (25 sec.), checking the quantity of fuel in the tank with the dip

stick, which is clipped inside the filler neck (30 sec.) and checking the tyre pressures (65 sec.). Thus the daily routine can be completed in 2 min.

The weekly check is naturally more comprehensive, and the first task is to carry out thdrough lubrication in accordance with the lubrication chart. To check the engine, gearbox and rear axle levels took 24 min. and to grease the 39 points took me 101. min., although this time could be reduced with practice because I had to crawl under the vehicle with a grease gun in one hand and the instruction manual in the other to find out the location of all the points which require attention.

An important job, which is all too often neglected, is to check the oil level in the fuel-injection pumpgovernor chamber, this being done by the removal of the level plug. This plug is situated at the back of the governor housing and is best reached from the near side of the engine, upon removal of the near-side cowl section. Checking the level took 2 min.

Battery Service

To check the electrolite levels in the two batteries occupied 6 min. One battery is situated under the mate's seat-board and it is merely necessary to lift up this board and remove the wooden steady beam to gain access to the cell caps. The right-hand battery is placed behind the driver's seat and has a wooden cover which is held in place with a clamp bar.

I adjusted the brakes by jacking up each wheel individually (a quick-acting hydraulic jack is provided in the tool kit) and to adjust all four wheels took 9 min. Checking the fan-belt tension required 15 sec. and examining the water hose connections for cleanliness or deterioration occupied a further 30 sec.

The primary fuel filter is on the near-side frame longitudinal between the cab and the fuel tank, and cleaning out the sediment bowl and washing the filter discs in clean fuel took 4 min. The total time for the seven weekly tasks was 341 min.

Inspection of the engine-oil cleaner and topping up the oil level in the bowl occupied 3 min. The filter is located above the floorboards in front of the control pedals, and to obtain access to the filter itself it is necessary to remove the cast aluminium silencer from the base. This is secured by two wing nuts and the filter cover is retained in place by a knurled screw.

Quick Adjustment

Tappet adjustment was made with the engine cold, and by pulling out the engine stop control it was easy to turn the engine over by operation of the electric starter. The adjusting time was 11 min., and this included the time spent in removing and replacing the rocker covers.

It is often wise to clean out the unloader valve filter of a braking system which operates wholly or partly by air pressure, just as a highly recommended practice is to drain out the reservoir at frequent intervals to remove any oil which might have been blown in from the compressor. To remove the filter it was necessary first to relieve the pressure in the reservoir by repeated applications of the foot brake. The felt element is retained by a large filter plug and this was removed and washed in petrol.

Below the element there is an outlet filter which is secured by four ,-f-in.-diameter bolts and this also was removed and similarly cleaned. The whole operation took 9 min., which included the time taken to relieve the pressure and to rebuild it by running the engine until the pressure reached 110 p.s.i.