HINTS ON MAINTENANCE.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

532.—Removing the Locking Collar from a Foden Rear Wheel.

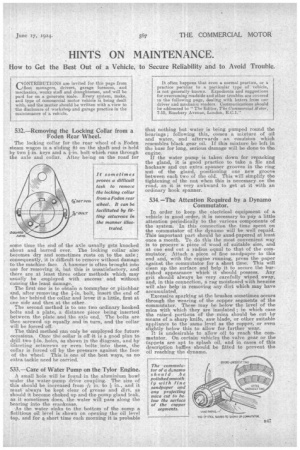

The locking collar for the rear wheel of a Foden steam wagon is a sliding fit on the shaft and is held by two fin. keys and a Fin.. bolt which runs through the axle and collar. After being on the road for some time the end of the axle usually gets knocked about and burred over. The locking collar also becomes dry and sometimes rusts on to the axle ; , consequently, it is difficult to remove without damage to the machine face. A hammer is often brought into use for removing it, but this is unsatisfactory, and there are at least three other methods which may usually be employed with success and without causing the least damage.

The first one is to obtain a tornrnybar or pinchbar and, after removing the On. bolt, insert the end of the bar behind the collar and lever it a little, first at one side and then at the other.

The second method is to use two ordinary hooked bolts and a plate, a distance piece being inserted between the plate and the axle end. The bolts are then screwed up equally and in turn, and the collar will be forced off.

The third method can only be employed for future occasions. Once the collar is off it is a good plan to drill two 4-in. holes, as shown in the diagram, and by inserting setserews or even bolts .into these, the collar is forced off by the pressure against the face of the wheel. This is one of the best ways, as no extra tackle need be carried.

533.—Care of Water Pump on the Tylor Engine.

A small hole will be foundin the aluminium bowl under the water-pump drive coupling. The size of this should be increased from Ain. to 4 in., and it must always be kept clear of grease and dirt, as should it become choked up and the pump gland leak, as it sometimes does, the water will pass along the bearing into the crankcase.

As the water sinks to the bottom of the sump a fictitious oil level is shown on opening the oil level tap, and for a short time each morning it is probable that nothing but water is being pumped round the bearings ; following this, comes a mixture of oil and water, and afterwards an emulsion which resembles black gear oil. If this mixture be left in the base for long, serious damage will be done to the engine. If the water pump is taken down for repacking the gland, it is good practice to take a file and hacksaw and cut extra spanner grooves in the ring nut of the gland, positioning one new groove between each two of the old. This will simplify the tightening of the nut when this is necessary on the road, as it is very awkward to get at it with an ordinary hook spanner.

534.—The Attention Required by a Dynamo Commutator.

In order to keep the electrical equipment of a vehicle in good order, it is necessary to pay a little attention periodically to the various components of the system. In this connection the time spent on the commutator of the dynamo will be well repaid. This important part should he sand-papered at least once a, month. To do this the most convenient way is to procure a piece of wood of suitable size, and at one end cut a radius equal to that of the commutator. Attach a piece of fine sandpaper to this end and, with the engine running, press the paper against the commutator for a short time. This will clean up the surface and help it to secure the burnished appearance which it should possess. Any grit should always be very carefully wiped away, and, in this connection, a rag moistened with benzine will also help in removing any dirt which may have accumulated, Excessive sparking at the brushes sometimes occurs through the wearing of the copper segments of the eommutator. These may be below the level of the mica with which they are insulated ; in which case the raised portions of the mica should be cut by means of a sharp knife, saw blade, or other suitable appliance to the same level as the copper, or even slightly below this to allow for further wear. It is undesirable to allow oil to reach the commutator. On certain vehicles the valve gear or the tappets are apt to splash oil, and in cases of this description baffles should be fitted to prevent the oil reaching the dynamo.