Machinery Loading . Simplified

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

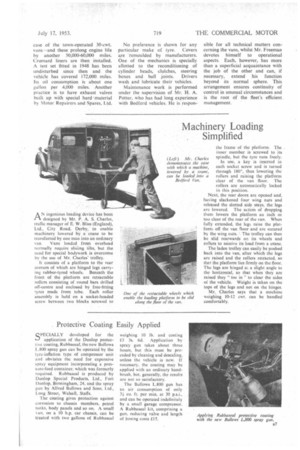

AN ingenious loading device has been designed by Mr. P. A. S. Charles, traffic manager of E. W. Bliss (England), Ltd., City Road, Derby, to enable machinery lowered by a 'crane to be transferred by one matt into an ordmary van. Vans loackx1 from overhead normally require sliding tilts, but the need for special bodyWork is overcome by the use of Mr. Charles' trolley, Ti consists of a platform to the rear corners of which arc hinged legs carrying rubber-tyred wheels. Beneath the front of the platform are retractable rollers consisting of round bars drilled off-centre and enclosed by free-fitting tyres made from tube. Each roller assembly is held on a socket-headed screw between two blocks screwed to

the frame of the platform. The inner member is screwed to its spindle, but the tyre runs freely.

In use, a key is inserted in each socket screw and is turned through 180°, thus lowering the rollers and raising the platform clear of the van floor. The rollers are automatically locked in this position.

Next, the rear doors are opened and, having slackened four wing nuts and released the slotted side stays, the legs are lowered. The action of dropping them lowers the platform an inch or too clear of the rear of the van. When fully extended, the legs raise the platform off the van floor and are secured by the wing nuts. ' The trolley can then be slid rearwards on its wheels and rollers to receive its load from a crane.

The laden trolley can easily be pushed back into the van, after which the legs are raised and the rollers retracted, so that the platform lies firmly on the floor. The legs are hinged at a slight angle to the horizontal, so that when they are raised they "toe in to clear the sides of the vehicle. Weight is taken on the tops of the legs and not on the hinges.

Mr„ Charles says that a machine weighing 10-12 cwt, can be handled comfortably.