HINTS ON MAINTENANCE.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen, and 1641. mechanics, works staff-and draughtsmen, and will be paid for on a generous scale. Every system. make, and type of commercial motor vehicle is being dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle, It often happens that even a normal practice, or a' practice peculiar to a particular type of vehicle, is not generally known. Expedients and suggestions for overcoming roads* and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should he addressed to " The Editor, The Commercial Motor, 7-15, Rusebery Avenue, London, E.C.1."

399.—Curing a Radiator Trouble on a Light Van Chassis.

The radiator on one example of a well-known type of van chassis had a habit of springing a leak in the bottom seam after travelling short distances over rough roads. The same trouble occurred if either of the front wheels were jacked up for tyre or wheel repairs, thus proving that the. radiator was strained at the foundation seam.

On 'examination it was discovered that the radiator was rigidly secured to the cradled chassis member by two A-in. setscrews. Mounting it on springs was Out Of the question, •as this upset the fitting of the bonnet. Rubber pads were also tried, but were unsuccessful: The trouble was eventually traced to the very small clearance, only 1-16 in., between the water outlet pipe from the radiator and the pump inlet pipe. Any twisting of the chassis franc caused these to foul each. other, as the three-point-suspended engine kept in line with the transmission.

:The difficulty was overcome by cutting a length of 1-in, off each pipe, thus leaving a gap of just over 2 ins. The two ends were then connected by a loosefitting hose provided with clips as far away from the ioint as possible, so that the maximum degree of flexibility was provided.

400.—Preventing Petrol Leakage on the' 30-cwt. W. and G.

On the W. and G. 30 cwt. chassis fitted with the Dorman engine trouble is sometimes experienced

owing to petrol leaking I thl! nipple of the union which connects the petrol pipe with the carburetter. The probable cause of the trouble is due to the fact that the petrol pipe leads from a strainer fixed to the front of the dash and down and up to the carburetter at an angle very little removed from the vertical, so that when travelling on rough' roads the pipe cannot absorb the movements which occur between the engine and the dash.

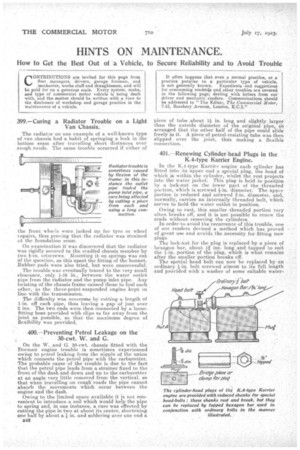

Owing to the limited space available it is not convenient to introduce a coil which would help the pipe to spring and, in one instance, a cure was effected by cutting the pipe in two at about its centre, shortening one half by about a 4 in. and soldering over one end a piece of tube about 14 in, long and slightly larger than the outside diameter of the original pipe, sO arranged that the other half of the pipe could slide freely in it. A piece of petrol-resisting tube was then slipped . over the joint, thus making a flexible connection. _ 401. Renewing Cylinder-head Plugs in the K.4-type Karrier Engine.

In the K.4.-type Karrier engine each cylinder has fitted into its upper end a special plug, the head of which is within the cylinder, whilst the rest projects into the water jacket. This plug is held_ in position by a, lock-nut on the lower part of the threaded poi tion, which is screwed fin. diameter. The upper Portion is reduced and screwed 4-in. diameter, and, normally, carries an internally threaded bolt, which serves to hold the water outlet in position..

Owing to rust, this smaller threaded portion very often breaks off, and it is net possible to renew the studs without .removing the cylinders.

In order to avoid the recurrence of this trouble, one of our readers devised a method which has proved of .great use and avoids the necessity for fitting new plugs.

The lock-nut for the plug is replaced by a piece of hexagon bar, about. If ins, long and tapped to suit the 4-in. ,portion of the plug, which is what remains after the smaller portion breaks off.

The spetial head bolt can now be replaced by an ordinary 4-in. bolt screwed almost. to its full length and provided with a washer of some suitable water

iesi8ting material such as fibre. This bolt must be of sufficient length to screw well into the hexagon bar . without coming into contact with the Upper portion of the plug. When arranging this new method of fitting, it is, of course, necessary to make use of the ordinary bridge piece which was formerly used under the lock-nut for pulling the plug into positton.