A Novel Form of Worm Steering Gear F ROM Burman and

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

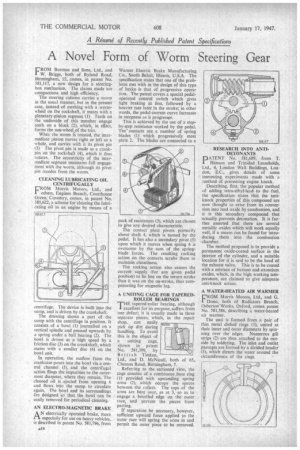

Sons, Ltd., and W. Briggs, both of Ryland Road, Birmingham, 15, comes, in patent No. 581,117, a new design for a steeringbox mechanism. The claims made are compactness and high efficiency.

The steering column carries a worm in the usual manner, but in the present case, instead of meshing with a wormwheel on the rockshaft, it mates with a planetary-pinion segment (1) Teeth on the underside of this member engage teeth on a block (2), which, in effect, forms the sun-wheel of the trio.

When the worm is rotated, the intermediate pinion moves right or left as a whole, and carries with it its pivot pin (3) The pivot pin is made as a crankpin on the rockshaft (4), which it thus rotates. The eccentricity of the intermediate segment maintains full engagement with the worm, although its pivot pin recedes from the worm.

CLEANING LUBRICATING OIL CENTRIFUGALLY rROM Morris Motors, Ltd., and others, Engines Branch, Courthouse Green, Coventry, comes, in patent No. 581,622, a scheme for cleaning the lubricating oil in an engine by means of a

centrifuge. The device is built into the sump, and is driven by the crankshaft.

The drawing shows a part of the sump with the centrifuge in position. It consists of a bowl (1) journalled on a vertical spindle and pressed upwards by a spring under a ball bearing (2). The bowl is driven at a high speed by a friction disc (3) on the crankshaft, which mates with a smaller disc (4) on the bowl unit.

In operation, the outflow from the crankcase pours into the bowl via a central channel (5), and the centrifugal action flings the impurities to the outermost diameter, where they remain. The cleaned oil is ejected from opening 6 and flows into the sump to circulate again. The bowl and its surroundings tire designed so that the bowl can be , easily removed for periodical cleaning.

AN ELECTRO-MAGNETIC BRAKE

A N electrically operated brake, more especially for use on heavy vehicles, is described in patent No. 581,796, from

pack of resistances (3), which are chosen to give any desired characteristic.

The contact plate pivots primarily about shaft 4, which is turned by the pedal. It has also a secondary pivot (5) upon which it moves when spring 6 is overcome by the sum of the spring-, blade forces. The resulting rocking action on the contacts scrubs them to maintain cleanliness.

The rocking action also causes the current supply (for any given pedal position) to be less on the return stroke than it was on the on-stroke, thus compensating for magnetic lag.

A UNITING CAGE FOR TAPEREDROLLER BEARINGS

THE tapered-roller bearing, although excellent for its purpose, suffers from one defect; it is usually made in three separate pieces, which, in the repair

shop, can easily pick Op dirt during handling. To avoid this is the object of a uniting cage, shown in patent No. 581,399, by British Timken, Ltd., and D. McNicoll, both of 65, Cheston Road, Birmingham, 7.

Referring to the sectioned view, the cage consists of a continuous base ring (1) provided with upstanding spring arms (2), which occupy the spaces between the rollers. The tops of the arms are bent over, as at 3, so as to engage a bevelled edge on the outer race, and prevent the pieces from parting.

If separation be necessary, however, sufficient upward force applied to the outer race will spring the arms in and permit the outer piece to be removed. RESEARCH INTO ANTIDETONANTS PATENT No. 581,689, from T. Hanson and Trinidad Leaseholds, Ltd., 4, London Wall Buildings, London, E.C., gives details of some interesting experiments made with a method of preventing engine knock.

Describing, first, the popular method of adding tetra-ethyl-lead to the fuel, the specification states that the antiknock properties of this compound are now thought to arise from its conversion into lead oxide by combustion, and it is this secondary compound that actually prevents detonation. It is further asserted that there are several metallic oxides which will work equally well, if a means can be found for introducing them into the combustion -chamber.

The method proposed is to provide a permanent oxide-coated surface in the interior of the cylinder, and a suitable location for it is said to be the head of the exhaust valve. This is to be coated with a mixture of barium and strontium oxides, which, in the high working temperature, are claimed to give adequate anti-knock action.

A WATER-HEATED AIR WARMER

FROM Morris Motors, Ltd., and G. Dono, both of Radiators Branch, Osberton "Works, Oxford, comes patent No. 581,586, describing a water-heated air warmer.

The unit is formed from a pair of thin metal dished rings (1), united at their inner and outer diameters by spinning over the edges. Numerous gill strips (2) are then attached to the outside by soldering. The inlet and outlet passages are formed by a divided header' (3), which directs the water around the circumference of the rings.