THE UPKEEP OF STEAM WAGONS.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

No. 10.—Dismantling and Re-erecting.

Sometimes ferrules are fitted in the firebox end of .the tubes if they leak very badly ; but it is advisable to avoid the use of these as much as possible. The ferrules throttle the passage of the hot gases through the tubes, at the very spot where as much space should be given as possible, and also seriously interfere with cleaning, as the tube brush will not pass through them. The result is that all the dirt in the tube is clogged into the ferrule. Also ferrules are easily put in, but they are ugly customers to get out. If they are found to be really necessary, the Barron expanding ferrules are undoubtedly the best; these can be tightened by knocking up the inner ferrule.

.Firebox.—The average life of a firebox, if well looked after and the water used is not very bad, is from 8 to 10 years, when using good coal as fuel. If coke is used the life will be reduced, on account of the sulphur given off by the burning fuel attacking the plates and causing them to waste away. During its lifetime various repairs may be necessary, as here described. Stays leaking is one of the most common defects, and they should be hammered up as soon as detected. Occasionally a stay will waste away and break, being detected by tapping, as described in the first article. To remove a stay; first chip off the heads and drill down each end about twice the thickness of the plates. The ends should then be chipped out with a round nose chisel, taking care not to damage the threads in the plate, when the stay will dime down inside the water-space and can be removed through one of the mud holes. Before fitting a new stay run tap through to clear away all chips ; if the plate is wasted it may be necessary to tap it out a larger size and fit a, larger stay. If the stays are made of steel they must be annealed before putting in, but if of good Low Moor iron this is not necessary. The ends are then hammered over cold and caulked.

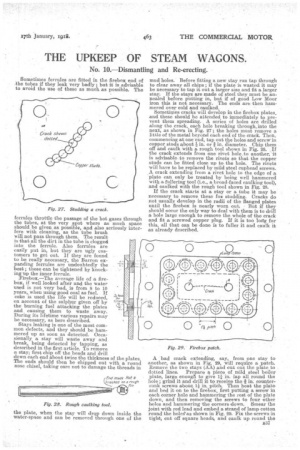

Sometimes cracks will develop in the firebox plates, and these should be attended to immediately to prevent them spreading. A series of holes are drilled along the crack, each hole breaking through.into the next, as shown in Fig. 27; the holes must remove a little of the metal beyond each end of the crack. Then, commencing at one end, tap out the holes and screw in copper studs about in. or I in. diameter. Chip them off and caulk With a rough tool shown hi Fig. 28. . If the crack extends from one rivet hole ,to another, it is advisableto remove the rivets so that the copper studs can be fitted close up to the hole. The rivets will have to be replaced by mild steel cuphead screws. A crack extending from a rivet hole to the edge of a -plate can only be treated by being well hammered with a flittering tool (i.e., a broad-faced caulking tool), and caulked with the rough tool shown in Fig. 28.

If the crack starts at a stay or a tube it may be necessary to remove these fog studding. Cracks do not usually develop in the radii of the flanged plates until the firebox is nearly worn out. But if they should occur the only way to deal with them is to drill a, hole large enough to remove the whole of the crack and fit a screwed copper plug. If it is too lorig for this, all that can be done is to fuller it and caulk it as already described.

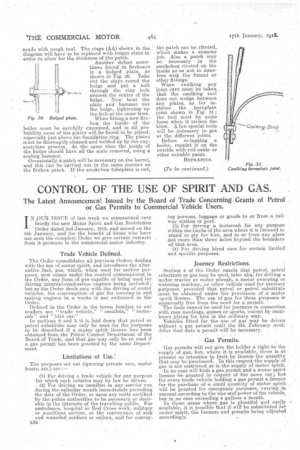

A bad crack extending, say, from one stay to another, as shown in Fig. 29, will require a patch. Remove the two stays (AA) and out out the plate to dotted lines. Prepare a piece of mild steel boiler plate, large enough to give 11 in. -lap all round the hole ; grind it and drill it to receive the fi in. countersunk screws about 1i in. pitch. Then heat the plate and bed it on to the firebox, first putting a screw in each corner hole and hammering the rest of the plate down, and then removing the screws -to four other holes and hammering the corners down. Smear the joint with red lead and embed a strand of lamp cotton round the holesbas shown in Fig. 29. Fix the screws in tight, cut off square heads, and caulk up round the

teads with rough tool. The stays (AA) shown in the diagram will have to be replaced with longer stays in order to allow for the thickness of the patch.

Another defect sometimes found in fireboxes is a bulged -plate, as shown in Fig. 30. Take out the stays round 'thebulge and put a bolt through the stay hole nearest the centre of the bulge. Now heat the plate and hammer out the bulge, tightening up the bolt at the same time.

When fitting a new fire-

_ box the inside of the boiler must be carefully examined, and in all probability some of the plates will be found to be pitted, especially just above the foundation ring. The places must be thoroughly cleaned and welded up by the oxyacetylene process. At the same time the inside of the boiler should have all the scale removed, using a scaling hammer. Occasionally a pitch will be necessary on the barrel, and thi,s can be carried out in the same manner as the firebox patch. If the srnokebox tubeplate is out, the patch can be riveted, which makes a sounder job. Also a patch may ne necessary. in the smokebox riveted on the inside so as not to interfere with the funnel or other fittings: When caulking any joint care must be taken. that the caulking tool does not wedge between any plates, as for instance the hornplate joint shown in -Fig. 31; the tool must be quite loose when it strikes the blow. A few special tools will be necessary to get at the different joints.

Before re-lagging a boiler, repaint it on the outside with red oxide or other suitable paint.

REPERST QS.