Design House

Page 25

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

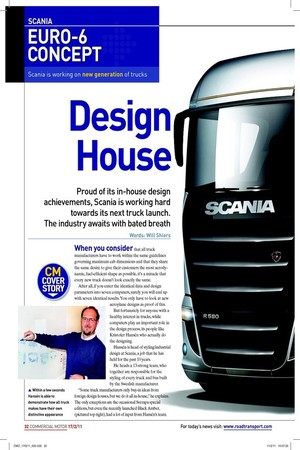

Proud of its in-house design achievements, Scania is working hard towards its next truck Launch. The industry awaits with bated breath

Words: Will Shiers

When you consider that all truck manufacturers have to work within the same guidelines governing maximum cab dimensions and that they share the same desire to give their customers the most aerodynamic, fuel-eficient shape as possible, it’s a miracle that every new truck doesn’t look exactly the same.

After all, if you enter the identical data and design parameters into seven computers, surely you will end up with seven identical results. You only have to look at new aeroplane designs as proof of this.

But fortunately for anyone with a healthy interest in trucks, while computers play an important role in the design process, its people like Kristofer Hansén who actually do the designing.

Hansén is head of styling/industrial design at Scania, a job that he has held for the past 10 years.

He heads a 13-strong team, who together are responsible for the styling of every truck and bus built by the Swedish manufacturer.

“Some truck manufacturers only buy-in ideas from foreign design houses, but we do it all in-house,” he explains. The only exceptions are the occasional Svempa special editions, but even the recently launched Black Amber, (pictured top right), had a lot of input from Hansén’s team. In 2004, at the launch of the R-Series, Scania announced that from that point on it would be embarking on a continual improvement programme, introducing gradual changes as and when they were needed.

However, last year it announced that there would be an exception to the rule, by way of an entirely new truck. While it remains tight-lipped as to when we will see it (although the smart money is on 2013 in time for Euro-6), what we do know is that Hansén and his team are busy working on it now. In fact, it has probably kept them busy for some years already.

“Depending on the size of a project, we could be working on it for anywhere from two to ive years ahead,” he says. “We started working on the latest R-Series three years before its launch. And the initial sketches were drawn earlier than that.”

The constraints

So where do you start when you’ve been asked to design a new Scania? Well irst things irst, you have to consider all the limitations and constraints and, in the world of truck design, there are plenty of them.

First and foremost, there are strict dimensions restrictions. Car designers can, within reason, go as wide, long and high as they wish, but when you are penning a new truck you don’t have this luxury.

For Hansén and his team, this is perhaps the greatest challenge. He would relish the opportunity to work with an extra couple of feet and says in the perfect world this would be shared equally between the front and the rear of the cab.

Such a change in legislation would enable him to add a small bonnet (or ‘bull-nose’) to the front end, improving safety, aerodynamics and engine cooling.

The additional length at the rear of the cab would result in more spacious living quarters for the driver. But Hansén is a realist and is well aware that if ever an increase in overall length was to be introduced in Europe, there would be huge pressure for it to be at the business end of the truck.

“We also get pressure from the various departments at Scania,” explains Hansén, and in the case of Euro-6, particularly the engine department. Every Euro-6 engine is going to require signiicantly more cooling than its Euro-5 equivalent, so large radiators and grilles need to be incorporated into the designs. The team also faces the challenge of packaging the SCR and EGR (as Euro-6 requires both) on the chassis.

The truck must also be as aerodynamic as possible, which is more crucial now than ever before. Not only does the cost of diesel continue to rise, but aerodynamics plays an important role in Scania’s ambition to manage Euro-6 without any fuel penalty.

“And it must be safe and very nice to drive too,” adds Hansén.

But perhaps the greatest challenge of all is ensuring that any new design must be instantly recognisable as a Scania, or in Hansén’s words, “it must have Scania DNA”.

But despite the numerous restrictions and challenges he faces, as you can see from the sketches, Hansén and his team are still able to create some stunning truck designs. And what’s more, there’s deinitely no mistaking the Scania DNA.

But coming up with ideas is one thing and actually seeing them evolve into concept vehicles is a different story altogether. “The car industry shows far more concepts than the truck industry,” explains Hansén.

He says car manufacturers tend to show them because they want to gauge reaction before deciding whether to put the vehicle into production. In contrast, truck makers tend to treat concepts as simply marketing exercises and they rarely intend to build anything that they show.

However, one exception to the rule was the Scania Longline (which Hansén’s team was deeply involved in). It received such incredible feedback that Scania put it into production.

New Scania

That leads us neatly to the question we ask on this week’s cover – is this the new Scania? Well, in short, no it’s not! If it was, Scania would not have let us walk out of its head ofice with the image. However, we haven’t lead you up the garden path entirely, because while Hansén is incredibly careful not to give away too many details, he does conirm that aspects of this vehicle are likely to appear on the next generation.

“What I can tell you is that it will be even more

beautiful than the current R-series,” he says with a grin. ■