The Works Goes to the Job

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

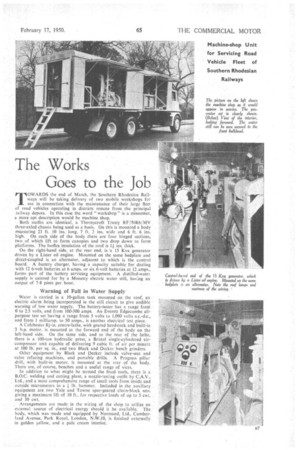

"10WARDS the end of March, the Southern Rhodesian Railways will be taking delivery of two mobile workshops for use in connection with the maintenance of their large fleet of road vehicles operating in districts remote from the principal railway depots. In this case the word " workshop " is a misnomer, a more apt description would be machine shop.

Both outfits are identical, a Thornycroft Trusty RF/NR6/MV three-axled chassis being used as a basis. On this is mounted a body measuring 23 ft. 10 ins. Jong, 7 ft. 2 ins. wide and 6 ft. 6 ins. high. On each side of the body there are four hinged sections, two of which lift to form canopies and two drop down to form platforms. The Isoflex insulation of the roof is 11 ins. thick.

On the right-hand side, at the rear end, is 'a 15 Kva generator driven by a Lister oil engine. Mounted on the same bedplate and direct-coupled is an alternator, adjacent to which is the control board. A battery charger, having a capacity suitable for dealing with 12 6-volt batteries at 6 amps. or six 6-volt batteries at 12 amps., forms part of the battery servicing equipment. A distilled-water supply is catered for by a Manesty electric water still, hav:ng an output of 7-8 pints per hour.

Warning of Fall in Water Supply Water is carried in a 10-gallon tank mounted on the roof, an electric alarm being incorporated in the still circuit to give audible warning of low water supply. -The battery-tester has a range from 0 to 2.5 volts, and from 100-300 amps. An Everett Edgecumbe all' purpose test set having a range from 5 volts-to 1,000 volts a.c.-d.c., and from I milliamp. to 50 amps., is another electrical test piece.

A Colchester 8f-in, centre-lathe, with geared headstock and built-in '3 h.p. motor, is mounted at the forward end of the body on the left-hand side. On the same side, and to the rear of the lathe, there is a 100-ton hydraulic press, a Bristol single-cylindcred aircompressor unit capable of delivering 9 cubic ft. of air per minute at 100 lb. per sq. in., and two Black and Decker bench grinders.

Other equipment by• Black and Decker include valve-seat and valve refacing machines, and portable drills, A Progress pillar drill, with built-in motor, is mounted at the rear of the body. There are, of course, benches and a useful range of vices.

• In addition to what might be termed the fixed tools, there is a B.O.C. welding and cutting plant, a nozzle-testing outfit by C.A.V., Ltd., and a most comprehensive range of small tools from inside and outside micrometers to a i lb. hammer. Included in the auxiliary equipment are two Yale and Towne spur-geared chain-block sets, giving a maximum lift of 10 ft., for respective loads of up to 5 cwt. and 30 cwt.

Arrangements are made in the wiring of the shop to utilize an external source of electrical energy should it be available. The body, which was made and equipped. by Normand, Ltd., Cumberland Avenue, Park Royal, London, N.W.10, is finished externally in golden yellow, and a pale cream interior.