Bellay equipped Bus ,uns to Schedule on Hard Test

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

C("10-OPERATION on the part of k...,those with specialized knowledge, pooling of resources, and readiness of all concerned to accept facts and to indulge in a certain amount of " give and take," are just the things that are now required to put the producer-gas vehicle on its feet. Enterprise, of course, is also called for, and those who now have the courage to embark on what is still something of an unknown quantity will not only gain full recompense but also will play a big part in promoting the welfare of the nation.

We were involved, last week, in the nucleus of a movement on these lines. We took part in a demonstration of an operator's bus, equipped by a prominent commercial-motor engineering company, with a gas-producermaker's plant, with the assistance of a number of manufacturers of auxiliaries, some seven companies having been associated in this enterprise.

Further interest, moreover, attaches to the conversion because the power unit, now running on gas, was formerly an oil engine.

In the course of a run of between 20 and 30 miles, over what any p.s.v. operator would describe as a definitely difficult route, it was unquestionably shown that this vehicle is a practical proposition. No trouble of any sort was experienced. Once the apparatus had thoroughly got going, the performance was not readily distinguishable from that of a petrol or oil bus. Two steep hills were climbed and pace was kept with a trolleyhus on normal service, its stops and starts being followed reasonably closely.

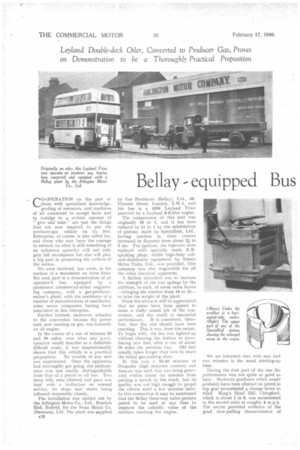

The installation was carried out by the Arlington Motor Co., Ltd., Ponders End, Enfield, for the Swan Motor Co. (Swansea), Ltd. The plant was supplied A22 by Gas Producers (Bellay), Ltd., 66, Victoria Street, London, S.W.1, and the bus is a 1936 Leyland Titan powered by a Leyland 8.6-litre engine.

The compression ofthis unit was originally 18 to 1, and it has been reduced to 11 to I by the substitution of pistons, made by Specialloid, Ltd., having cavities in their crowns increased in diameter from about 21 to 3 ins. For ignition, the injectors were replaced with specially made E.R. sparking plugs, whilst high-duty coil • and-distributor equipment by Simms Motor Units, Ltd., was provided. This company was also responsible for all the other electrical apparatus.

A further alteration was to increase the strength of the rear springs by the addition, to each, of seven extra leaves —bringing the number from 18 to 25— to take the weight of the plant.

From the above it will be appreciated that no pains have been spared to make a really sound job of the conversion, and the result is successful

performance. It is consistent, therefore, that the test should have been exacting. This it was, from the outset. To begin with, the fire was lighted-up without cleaning the firebox or introducing new fuel, after a run of about

20 miles the previous day. Old fuel usually takes longer than new to reach the initial gas-making state.

In this case a 50-50 mixture of Progasite (high moisture content) and Suncole was used. Gas was being generated within about six minutes from putting a match to the torch, but its quality was not high enoa,gh to propel the vehicle until a few minutes later. "En this connection it may be mentioned that the Bellay three-way valve permits petrol to be used at any time to improve the calorific value of the mixture reaching the engine,

We are informed that with new fuel two minutes is the usual starting-up time.

During the first part of the run the performance was not quite so good as later. Moderate gradients which would probably have been climbed on petrol in top gear necessitated a change down to

third. King's Head Chingford, which is about 1 in 8, was surmounted in the second ratio at roughly 8 m.p.h. The ascent provided evidence of the good slow-pulling characteristics of producer gas, and a marked feature of the performance. was the entire absence of knocking or pinking.

A speed on the level of over 30 m.p.h. was attained shortly after this climb and then a:slope of 1 in 5; named Friday Hill, was tackled. First gear was demanded and on the worst section a momentary whiff of petrol was

required. We were informed, however, that, on the day before, this hill had been climbed on gas alone.

To gain an idea of how long a stop could be made with the engine switched off, we interrupted the trial for about 40 minutes. After this period had elapsed the fuel visible through the tuvere was seen to be still glowing, and under three minutes of running on petrol sufficed to draw it up and produce good gas.

We took speed readings for acceleration on the level which showed that, starting from rest in second gear, 25 m.p.h. was attained in 55 seconds, the gear changes being effected at about 8 m.p.h. and 15 m.p.h., respectively. These figures, however, must not be regarded as reliable, for we had no opportunity of checking the speedometer, which appeared to be indicating a little low.

Impressions, in these circumstances, may be of greater value than figures, and we can state, with no exaggeration, that, as observed from the lower saloon, the bus performed in absolutely normal manner, negotiating the sharp turns, slow climbs, and numerous difficulties of the course, in so effortless and unostentatious a manner that the attention of uninitiated passengers would certainly not be drawn to its unorthodox power source.

Briefly to run through the features of the Bellay plant, the producer is of the cross-dry-draught type, having a downward sloping water-cooled tuyere with fish-tail orifice. A separate radiator is used for dissipating its heat. The hopper and furnace are of square section, with a waist between them, at which the feed of fuel can be cut off, and which is shaped to regulate the supply of fuel to the fire.

From the producer the gas flows to two vertical tubes, which function as coolers and for dust depositing, and thence via a multi-tube horizontal radiator to the main filter, Provision is made for by-passing the vertical tubes when it is desired to warm up the filter for drying out the cleaning media. This comprises granulated cork and a series of fabric elements. A thermometer is incorporated in the system at the filter outlet.

Between the apparatus at the rear of the vehicle and the mixing valve under the bonnet, there is only a plain pipe connection. The valve performs the following functions :—Switching over from petrol to gas; shutting off the carburetter; admitting a mixture of petrol vapour and producer gas; shutting off the gas supply; regulating the quantity of gas admitted. The air valve can be controlled manually.

This model producer plant costs £125, and is stated to consume anthracite fuel at the rate of 2.25 lb. per mile.

In reporting this test we have perhaps over-emphasized the shortcomings of producer gas as compared with petrol. We have dome so deliberately, however, because, in our view, it is futile to attempt to convince operators and the public that the gas vehicle has reached a stage of development when its performance is level with that of a comparable liquid-fuel machine. The present position is that it is necessary for all to put up with many inconveniences and for the time being producer gas is showing itself to be a very satisfactory second fiddle for transport.

There is room for improvement, and promising avenues are now being explored. Encouragement, by supporting gas, and patience, will bring further developments which are likely ultimately to put the gas-vehicle in a position where it is preferred, even when petrol and oil become available again in unrestricted quantities.