German Technical Ter encies as Revealed by

Page 46

Page 47

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

THE BER ACLOSE survey of the International Motor Show in Berlin reveals much of interest in connection with the development of the oil engine, but little in respect of other parts of the chassis, with the exception of a few outstanding examples. In writing this we are comparing the present Show with that held two years ago. The report concerning the private-car exhibits, which was published in last Tuesday's issue a our associated journal, The Motor, appears to indicate considerably more relative progress on that side of the German industry. .

The past two years may be looked upon as a period of " cleaning up," with regard to both makers and their products. There has been a certain amount of linking up between hitherto opposing interests, whilst several unconventional designs, such as the Rumpler and certain types of six-wheeler, have dropped out, at least so far as the Show is concerned. Other new models which have appeared this year 8how a distinct tendency towards British design.

Clutches are nearly all of the dry-plate pattern, single or multiple; about three-quarters of the gearboxes form a unit with the engine, they are often of the constant mesh silent type, and in the heavier models have supplementary gears giving up to eight ratios for forward running.

We did not notice any effort towards automatically changing or "in-finite-ratio. " gearboxes, which is sonamhat surprising as German makers are usually keen on the development of anything which enables them to strike out In a fresh direction.

The open caMan shaft, usually in two sections, is popular, but in the heavy machines it is often employed with a spherically headed torque tube. Most of the lighter models are of conventional pattern with helical-bevel gearing, but either double-reduction pinions in the centre or external-spur-gear drives at the hubs are used on medium and heavy types. The absence of the wormnal drive is most marked, although it is to be found on the new Krupp six-wheeler.

Chassis suspension has received a fair amount of attenE32

tion, most of the heavy vehicles have auxiliary springs, and in the Bussing-N.A.G. six-wheeler curved plates set edgewise above the bogie springs reduce the effective length under load and thus provide automatic adjustment of the strength. Several makers, including Mercedes-Benz, have recently adopted slipper-type mountings in place of shackles, any rebound being checked by large-diameter rubber rollers. Some of the spring ends are mounted between compressed rubber cushions carried in cast casings.

The Krupp six-wheeler has its rear wheels mounted on arms pivoted to the narrowed portion of the chassis frame and connected by bell-cranks to the longitudinal enclosed coil springs -with which we are familiar in previous models of the same make. Others, chiefly amongst the smaller chassis of the parcelcar class, have no rear axles, but parallel cross-springs with cardan-shaft drive to each wheel from a centrally slung final-drive and differential gear.

The majority of the engines is rubber mounted, mostly in the normal position at the front, but a notable exception is the new Hanomag 3i-tonner, in which the four-cylindered power unit is slung across the chassis under the frame, together with the gearbox, and a 2-ft. 6-in, propeller shaft with two Spicer joints takes the drive to a double-reduction rear axle. This model has forward control and thus constitutes a handy vehicle with ample loading space on a short wheelbase.

Other petrol power units and their arrangement show some novelty; there is the Bussing-N.A.G. vee-eight of 155 b.h.p., with the water pump and dynamo mounted between the two banks of cylinders and driven in line with an eightbladed fan. This is shown both in and out of a chassis.

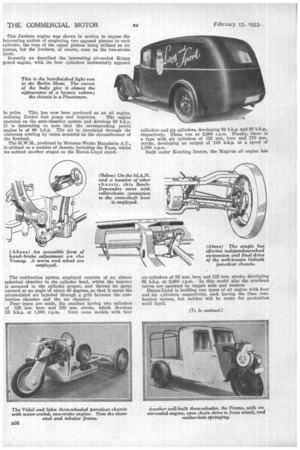

Then there is the twin-six unit of the same make. This comprises two distinct engines with two crankshafts, flywheels, dynamos, magnetos, four carburetters, etc., but one crankcase. Each engine has its separate gearbox and propeller shaft and at high speeds on level roads one unit can be cut out, which is perhaps as well, for the two give 320 b.h.p., propel a giant six-wheeled bus at 75 m.p.h., and

must consume a lot of petrol. Five of these buses have been built and are operating in South Germany.

A " double" engine, which is more truly a unit, is the Hensehel 12-cylinder, with two crankshafts geared together and the drive taken from one of them. Everything is duplicated except the fan. Apart from the small engines there are two air-cooled types which deserve especial mention; these are the new Krupp with four cylinders opposed in pairs, a powerful fan flywheel and adequate cowling, and the four-cylinder-in-line Phanomen, with its blower flywheel and air ducts to the deeply finned cylinders. This unit is used in the Phanomen " Grailit " 14-tanner.

On the whole, -brakes have been considerably improved, the number of cross-shafts and other parts through which so much .effort can be lost, has been cut down. The BoschDewandre vacuum servo is very popular and has displaced other types on many chassis; the Knorr compressed-air braking system is, however, used on some heavy machines.

The hydraulic system is also gaining ground and is used on many Bilssing-NAG models. From certain brake shoes which we saw displayed it appears that some of the linings used are unnecessarily thin and hardly likely to give a long life, although the actual area is generous. Transmission brakes—onee so popular in Germany—are dying out except for parking purposes and this only in a few examples.

Free-wheel devices are almost conspicuous by their absence.

Chassis frames display but little novelty. There is, of course, the immense Tatra six-wheeler, but this is not a German make. It has a huge tubular " backbone " and massive coil springs. In one of the M.A.N. chassis the channel-steel frame has cross-members welded to the side members. Reference has already been made to the Krupp six-wheeler, the frame of which is inswept from normal width to about 15 ins, so that the wheels ean be given full play.

Now we will revert to oil engines. There is a large number of these, some definitely successful, other's more or less experimental. As a well-known German engineer put LIto us, in a few cases the externals looked all right, but if might be difficult to find the crankshafts. clers in pairs.

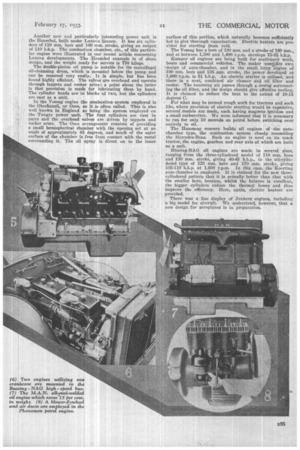

The most successful, so far, is, of course, the MercedesBenz, which is very popular both in Germany and other parts of the world, including England. Engines of this make are built in various horse-powers, but are all of the ante-chamber or pin-combustion type, with electric heaters to facilitate starting from cold. As an example of the economy of these units, the type used on the 2-tonner runs 22 miles to the gallon as compared with the 12-14 m.p.g. of a petrol engine employed in a vehicle of this capacity.

Perhaps the most interesting new unit is the latest M.A.N. The company has built oil engines for many years, but the type to which we refer is built from electrically welded sheet steel, with a light-metal sump. It has a bore of 120 mm. and a stroke of 180 mm., and develops 110 b.h.p., whilst the weight is 680 kilogs. The six cylinders have a capacity of 12.2 litres, and it is claimed that the method of construction .gives a weight saving of 15 per cent. So far as its appearance is concerned, it looks entirely conventional and few would suspect the method of its construction except by rapping with the knucldes.

The M.A.N. engine of standard pattern is also built in other capacities, the largest being a six-cylindered model of 16.6 litres (140 rem. bore and 180 tem, stroke), which develops 140-150 b.h.p. The injection system is direct into the cupped pistons Another new and particularly interesting power unit is the Henschel, built under Lanova licence. It has six cylinders of 110 mm. bore and 160 mm. stroke, giving an output of 110 b.h.p. The combustion chamber, etc., of this particular engine were illustrated in our recent article concerning Lanova developments. The Henschel example is of clean design, and the weight ready for service is 770 kilogs. The double-pinion oil pump is notable for its centrifugal oil-cleansing drum, which is mounted below the pump and can be removed very easily. It is simple, but has been found highly efficient. The valves are overhead and operate through tappets and rocker arias; a point about the latter is that provision is made for lubricating them by hand. The cylinder heads are in blocks of two, but the cylinders are cast as a unit.

In the Vomag engine the combustion, system employed is the Oberhansli, or Omo, as it is often called. This is also well known in England as being the system employed on the Tangye power unit. The four cylinders are cast in pairs and the overhead valves are driven by tappets and rocker arms. The Omo arrangement consists of providing a small hemispherical chamber with the opening set at an angle of approximately 45 degrees, and much of the outer surface of the chamber is free from contact with the metal surrounding it. The oil spray is direct on to the inner

surface of this portion, which naturally becomes sufficiently hot to give thorough vaporization. Electric heaters are provided for starting from cold.

The Vomag has a bore of 130 ram, and a stroke of 180 tam., and at between 1,300 and 1,400 r.p.m. develops 75-85 b.h.p.

Kemper oil engines are being built for stationary work, boats and commercial vehicles. The maker uses:;4'tliis own • design of ante-chamber, and in the small lorry engine of 100 mm. bore and 136 mm. stroke, the power developed at 1,800 r.p.m. is 51 b.h.p. An electric starter is utilized, and there is a neat, combined air cleaner and oil filter and cooler. The incoming air passes through a casing surrounding the oil filter, and the design should give effective Cooling. It is claimed to reduce the heat to the extent of 10-15 degrees C.

For what may be termed rough work for tractors and such like, where provision of electric starting would be expensive, several models are made, each having magneto ignition and a small carburetter. We were informed that it is necessary to run for only 10 seconds on petrol before switching over entirely to oiL

The Hanomag concern builds oil engines of the antechamber type, the combustion system closely resembling the Mercedes-Benz. Such an engine is used on its track tractor, the engine, gearbox and rear axle of which are built as a unit.

Bussing-NAG oil engines are made in several sizes, ranging from the three-cylindered model of 110 mm. bore and 130 mm. stroke, giving 40-45 b.h.p., to the six-cylindered type of 125 mm. bore and 170 ram. stroke, giving 105-110 b.h.p. at 1,400 r.p.m. In this case, the Koerting ante-chamber is employed. It is claimed for the new threecylindered pattern that it is actually better than that with the smaller bore, because, whilst the balance is excellent, the bigger cylinders reduce the thermal losses and thus improve the efficiency. Here, again, electric beaters are provided.

There was a fine display of Junkers engines, including a big model for aircraft. We understand, however, that a new design for aeroplanes is in preparation.

One Junkers engine was shown in section to expose the interesting system of employing two opposed pistons in each cylinder, the tops of the upper pistons being utilized as air pumps, for the Junkers, of course, runs on the two-stroke cycle.

Recently we described the interesting air-cooled Krupp petrol engine, with its four cylinders horizontally opposed in pairs. This has now been produced as an oil engine, utilizing Deckel fuel pump and injectors. The engine operates on the ante-chamber system and develops 50 bap. It is interesting to note that the corresponding petrol engine is of 60 b.h.p. The air is circulated through the elaborate cowling by vanes mounted on the circumference of the flywheeL The M.W.M., produced by Motoren-Werke Mannheim A.G., is utilized on a number of chassis, including the Faun, whilst we noticed another staged on the Hansa-Lloyd stand.

The combustion system employed consists of an almost spherical chamber in the cylinder head, whilst the injector is mounted in the cylinder proper, and throws its spray upward at an angle of about 45 degrees, so that it meets the accumulated air injected through a grill between the combustion chamber and the air chamber.

Four types are made, the smallest having two cylinders of 105 ram. bore and 150 mm. stroke, which develops 25 b.h.p. at 1,500 r.p.m. Next come models with four cylinders and six cylinders, developing 62 b.h.p. and 95 bap., respectively. These run at 2,000 r.p.m. Finally, there is a type with six cylinders of 125 mm. bore and 170 ram. stroke, developing an output of 110 b.h.p. at a speed of 1,300 r.p.m.

Built under Koerting licence, the Magirus oil engine has six cylinders of 88 ram. bore and 125 mm. stroke, developing 65 b.h.p. at 2,000 r.p.m. In this model also the overhead valves are operated by tappet nods and rockers. Hansa-Lloyd is building two types of oil engine with four and six cylinders, respectively, each having the Omo combustion system, but neither will be ready for production until April.

(To be continued.)