HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

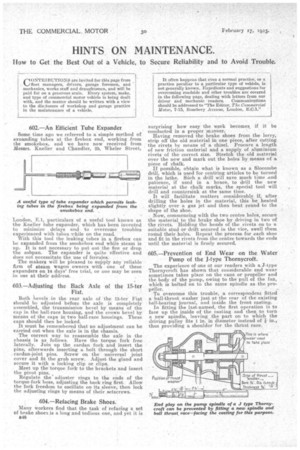

602.—An Efficient Tube Expander

Some time ago we referred to a simple method of expanding tubes at the firebox end, working from the• smokebox, and we have now received from Messrs. Kneller and Chandler, 25, Wheler Street, London, E.1, particulars of a useful tool known as the Iineller tube expander, which has been invented to minimize delays and . to overcome troubles experienced with tubes while on the road. With this tool the leaking tubes in a firebox can be expanded from the srnokebox end while steam is up. It is not necessary to put out the fire or drop the ashpan. The expander is quite effective and does not necessitate the use of ferrules.

The makers will be pleased to supply any reliable firm of steam wagon owners with one of these expanders on 14 days' free trial, or one may be seen in use at their address.

603.—Adjusting the Back Axle of the 15-ter Fiat.

Both bevels in the rear axle of the 16-ter Fiat should be adjusted before the axle is completely assembled, the transmission bevel by means of the cap in the ball-race housing, and the crown bevel by means of the caps in two ball-race housings. These caps should then be locked.

It must be remembered that no adjustment can be carried out when the axle is in the chassis.

The correct way to reassemble the axle in the chassis is as follows. Rave the torque fork free laterally. Join up the cardan fork and insert the pins, afterwards inserting a bolt through the short . cardan-joint pins. Screw on the universal joint cover and fit the grub screw. Adjust the gland and secure it with a hacking clip or clips. Meet up the torque fork to the brackets and insert the pivot pins.

Regulate the adjuster rings to the ends of the torque-fork boss., adjusting the back ring first. Allow the fork freedom to oscillate on its sleeve, then lock the adjusting rings by means of their setscrews.

&W.—Refacing Brake Shoes.

Many workers find that the task of refacing a set of brake shoe.s,is a longhand tedious one, arid yet it is 1146

surprising how easy the work becomes if it be conducted in a proper manner. Having removed the brake shoes from the lorry, strip off the old material in one piece, after cutting the rivets by means of a chisel. Procure a length of new friction material and a supply of aluminium rivets of the correct size. Stretch the old material over the new and mark out the holes by means of a piece of chalk.

If possible, obtain what is known as a Slocombe drill, which is used for centring articles to be turned in the lathe. Such a drill will save much time And patience, if used in a brace, to drill the new material at the chalk marks, the special tool will drill and countersink at the same time.

It will facilitate matters considerably if after drilling the holes in the material, this be healed slightly over a gas jet and then bent round to the shape of the shoe.

Now, commencing with the two centre holes, secure the material to the brake shoe by driving in two of the rivets. Holding the heads of the rivets on to a suitable stud or drift secured in the vice, swell them round their holes. Repeat the process for each shoe and fit in the rivets from the centre towards the ends until the material is firmly secured.

605.—Prevention of End Wear on the Water Pump of the I-type Thornycroft.

The experience of one of our readers with a 3.-type• Thornycroft has shown that considerable end wear sometimes takes place on the vane or propeller and the body of the pump, owing to the pull of the fan, which is bolted on to the same spindle as the propeller.

To overcome this trouble, a correspondent fitted a ball-thrust washer just at the rear of the existing ball-bearing journal, and inside the front casting. In fitting the last-named, the first operation is to face up the inside of the casting and then to turn a new spindle, leaving the part on to which the driving pulley fits 1 in, in diameter instead of thus providing a shoulder for the thrlist race.