How' WE CAN PROFIT )1\4 AERO-ENGINE DESIGN

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Features in an Aircraft Auxiliary Unit which Might be Introduced to Advantage in Commercial-vehicle Engines. An Out. standing Example of .an Air cooled " Flat" Engine Embodying the Single sleeve Valve Principle

WRITERS in the columns of this journal haw., from. time to time, dealt with various aspects of the " flat" engine,, of air cooling and of sleeve valves, all of. which havebeen treated as possible developments worthy of exploitation with a view to their adoption in engines intended for use in road-transport vehicles.

In view of this tendency, it is thought that a unit produced by Rota] Airscrews Ltd., and which is described as an auxiliary generating plant for aircraft, justifies mention in these columns, more particularly, of course, from the point of view of the type of engine employed,

Admittedly, the unit follows aero-engine design, but as it has been: built for a purposeother than as a prime-mover for an aeroplane-, it would appear that it ha s distinct possibilities in directions other than that for which it has been SpecficalLy designed and built.

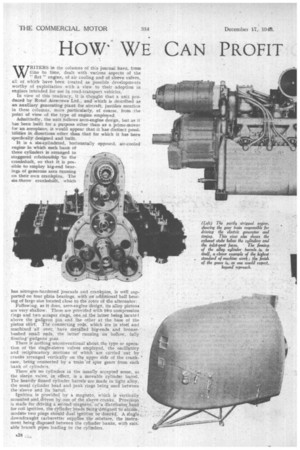

It is a six-cylinclered, horizontally opposed, air-cooled engine in which each bank of three cylinders is arranged in staggered relationship 'to the crankshaft, sothat it is passible to employ big-end bear-. ings of generous area running on their own crankpins. The six-throw crankshaft, which has nitrogen-bard'ened journals and crankpins, is well supported on four plain bearings, with an additional ball bearing of large-size located close to the rotOr Of the alternator:

Following, as it does, aero-engine design, its alloy pistons are 'very shallow. These are provided with tfvo compression rings and two scraper rings, one of the latter being located above the gudgeon pin and the other at the base of the piston skirt. The connecting rods, which are in steel and machined all over, haVe metalled big-ends and bronzebushed small ends, the latter' running on hollow, fully floating gudgeon pins.

There is nothing unconventional about the type or operation. of the single-sleeve valves employed, the oscillatory and reciprocatory motions of which are carried out by cranks arranged vertically on the upper side of the crankcase, being connected by a train of spur gears from each hank of cylinders. .

There are no cylinders in the usually accepted sense, as the sleeve. valve, fir effect, is a movable 'cylinder barrel. The heavily finned cylinder barrels are Made in light alloy, the usual cylinder head and junk rings being used between the sleeve and its banel.

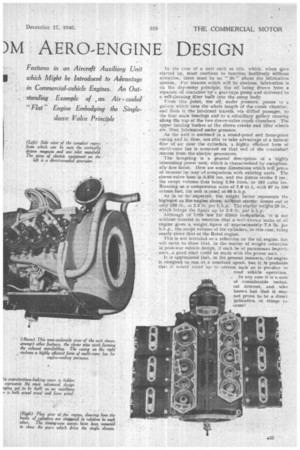

Ignition is provided by a magneto, which is vertically mounted and cfriv en by one of the sleeve cranks. Proviiion is made for, driving a seCOnd Magneto, or-a distributor head for coil ignition, the cylinder heads' being designed to accoin, modate two plugs shoulddual ignition be desired. A single clowndraught carburetter supplies the mixture, the instrument being disposed between the cylinder banks, with suitable branch pipes leading to the cylinders. • In the case of a unit such as this, which, when (Ince started up, must continue to function faultlessly without attention, there must be no ifs" about the lubrication system,. For reasons which will be obvious, lubrication is on the dry-sump principle, the oil being drawn from a separate oil container by a gear-type pump and delivered to a self-cleaning f titer built into the sump body.

From this point, the oil, under pressure, passes •,o gallery which runs the whale length of the crank chamber. and from it the lubricant travels, via drilled passages, to the four main bearings and to a subsidiary gallery running. along the top of thetwo sleeve-valve crank chambers, The • upper bearing bushes of the sleeve cranks and idler wheels are, thus, lubricated under pressure.

As the unit is enclosed in a sound-proof and fumeproot 'casing and is, thus, not able to take advantage of a natural flow of air over the cylinders, a highly efficient form of multi-vane fan is mounted cut that, end of the crankshaft remote from the electric generators.

The foregoing is a general description of a highly interesting power unit, which is characterized by exceptionally fine finish. Here are some dimensions .which will prove of interest by way of comparison with existing units. The sleeve-valve bore 15 3.375 ins, and the piston stroke 3 ins.. the swept volume thus being 2.64 litres, or 161 cubic ins. Running on a compression ratio of 7.8 to 1, with 87 to fOn octane fuel,. the unit is.rated at 60 b.h.p.

As is to be expected, the weight factor represents the highspot as, the: engine alone, without starter, comes out at only 1,50 lb., or 2.5 lb. per bih.p. The starter weighs 25 which brings the figure up to 2.9 lb.. per b.la.p.

Although of Tittle use for ditect corfiparison, it is not without interest to tnention that a ,well-known make of oil engine gives a weight.figure of approximately 7.5 lb, per h.h.p., the swept volume of the cylinders, in this case, being nearly twice that of the Rotol engine.

This is not intended as a reflection on the Oil engine, but . will serve to show that, in the matter of u-eight reduction in post-war vehicle design, if such be.of paramount importance, a gond start could be made with the power unit.

It is appreciated that, in the present instance, the engine is designed torun at a constant speed, but it is 'probable that it would stand up to -service such as is peculiar to

• road vehicle operation.

In-any ease it is a unit of Considerable technical interest, and who knows but that it mav not prove to he a direct indication of things to come?