Engineering Applied to Coachbuilding

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

Obtaining Rigidity on Bodies Built Down to a Weight. Simplicity of New Adjustable Seating

BODYBUILDING on mass, or even quantity-production lines, where price and weight are vital factors, calls for the same procedure as is adopted in chassis construction. Just as the real art of fitting is but seldom practised in the erection shops of vehicle builders, so we find that in bodybuilding it becomes a matter simply of erecting a specified number of jig-built units.

This method of construction is adopted by Gurney and Ewer, Ltd., Ruislip, Middlesex, which, apart from an occasional body made to special order, builds large numbers of van bodies of a specified type for a popular make of 20-25-cwt. forward-control chassis.

. The erection of the jig-built units,. comprising the body and cab, entails no more work than building up a portable shed or garage, but it is improbible whether, without special bracing, a body so built would stand up to the strenuous conditions met in service.

• In the case of the bodies built by Gurney and Ewer, Ltd., great rigidity is given to the whole structure by the use of a number of shallow-sectioned, light angle brackets bridging the top corners from side to roof.

A constant source of trouble is that known as "weaving," and this is overcome by using two door dovetails, fitted to the centre of the after end of the floor, to register with steel-lined slots formed in the doors. The doors are thus positively located and relative movement Letween them and the body is prevented.

Door Stop in Two Parts.

The door stops are interesting in that the arm is in two -parts, held together by a spring-loaded pin. By pushing the pin upwards the doors can be swung to the full limit of the hinges so as to permit of the vehicle being backed close up to a loading platform.

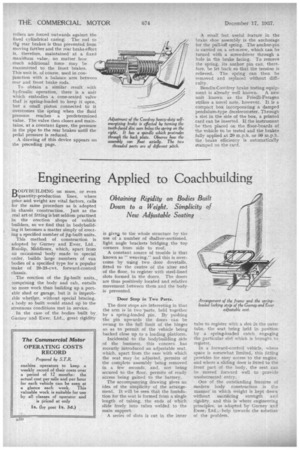

Incidental to the bodybuilding side of the business, this concern has recently introduced an adjustable seat, which, apart from the ease with which the seat may be adjusted, permits of the complete assembly being removed in a few seconds, and, not being secured to the floor, permits of ready access being gained to the battery.

The accompanying drawing gives an idea of the simplicity of the arrangement. It will be seen that the foundation for the seat is formed from a single length of tubing, the ends of which slide freely into tubes welded to the main support.

A series of slots is cut in the inner

tube to register with a slot in the outer tube, the seat being held in position by a spring-loaded catch engaging the .particular slot which is brought to register.

In a forward-control vehicle, where space is somewhat limited, this fitting provides for easy access to the engine, and where a sliding door is fitted to the front part of the body, the seat can be moved forward well to provide unobstructed entry.

One of the outstanding features of modern body construction is the manner" in which weight is kept down without sacrificing strength and rigidity, and this is where engineering principles, as adopted by Gurney and Ewer; Ltd;'help towards the solution of the problem.