Improving

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

DETAILS of DESIGN

Novel Features of Construction which make for ,Better Performance and Easier Maintenance. Where Improvement is Needed

NOW that the busy atmosphere of the nine days—during which Olympia opened its doors, to visitors to the Commercial Motor Exhibition—has given place to that of normal -business, we may welI conSider features of the design of chassis as revealed at the Show. As this display of itahistrial vehicles and chassis is now a biennial event, this review amounts to a survey of certain aspects of progress during the

past two years. •

With regard to general design, it would appear that the present form of vehicle calls for no special alteration and that 'it is giving satisfactory service; otherwise we Should have seen efforts made to get away from the conventional.

I was told that I should see all sorts of startling novelties, but this was by no means the case; as the only points which could be, classed as novelties were confined to details of construction.

Among the detail • improvements noticed, those on certain Dennis vehicles appear to be of a very practical nature. By an ingenious arrangement " the rocker casing of the Arrow model is made to hinge on centres Which coincide with the fW.S of the camshaft; by removing nuts and screws the valve gear may be tilted up so that the head is

easily removed. The hinge is so arranged that it is not a tight fit on its pins ; the object of this is to allow a gas-tight joint to be mime_ no matter bow thick or thin the gasket only be.

Another useful improvement on the same engine is the arrangement for timing the camshaft, both for assembly and for compensating for wear or stretch of the driving chain. Part of the camshaft is marked to correspond with a pointer and segmental slots are provided in the CA0

likely to alter. In the Dennis Arrow a simple provision is made by means of which the pedal can easily be brought back to its original position. A worm is provided in the place usually occupied by a clamping bolt. This worm engages recesses out in the shaft; by rotating the worm the relative positions of the lever and shaft can be adjusted.

The use of "wet" cylinders would appear to be gaining in popularity, but the Dennis barrels are made of a specially hard east-iron, so hard, indeed, that ordinary tools will not cut it; specially hard cutters have to be used and grinding is employed for finishing.

Ingenious Brake Design.

Among the few departures from standard practice, the Maudslay toggleoperated brake attracted some attention. As will be seen from an accompanying sketch, the pressure of a lever has the effect of spreading outward a pair of links, so expanding the flexible band which carries the brake facing. This is on ingenious application of a wellknown principle in which the reaction may be made to assist in the braking effect. A large C-shaped spring con-tracts the ends of the links to hold the brake in the " off " position.

On the Maudslay stand was an example of the 10-ton six-wheeler, in which only two wheels are driven, the rear wheels of the bogie being merely trailing ones. In this instance the rear ends of the main semi-elliptic springs are connected by long shackles to levers, the central fulcrums of which are borne by brackets _extending downward from the frame. To the rear ends of these levers the axle of the trailing wheels is

attached by hall joints; obviously' percentage of the weight is carried by the wheels of the trailing axle. By this means a balance of weight is provided between the driving and the trailing wheels. The two axles of the bogie are of different lengths, so that each set of wheels has,a track of its own.

The old problem of securing a gudgeon pin in its piston would appear to have been satisfactorily solved by a device shown on the stand of the Automotive Engineering Co., Ltd., of Twickenham, makers of the B.H.B. pistons. This simple device takes the place of the wire ring often used' for springing into a groove formed in the piston for its reception. In the present case the ring is formed by a steel pressing, the edge of which is ground so that it Ets accurately in the groove. It is of spring temper and can be contracted for insertion by means of a pair of round-nosed pliers. On the same stand was a eare fully designed thermostat arrangement by means of which the temperature of the mixture entering the cylinders is kept at a constant figure.

The arrangement for lifting spare wheels.shown on the Karrier stand was one of the few novelties of the Show. By means of a segmental rack and a pinion on the shaft on which the spare wheel is mounted, it can be raised or lowered simply by revolving it. "

As fair criticism is, or should be, welcomed by all responsible for design and progress, I will give my unbiased opinion on some of the designs shown.

Unit construction of the engine and gearbox appears to be becoming almost.

generally adopted. It is hard to swim against the stream, but to many who have maintenance entrusted to them this• method of construction does not appeal; they prefer to be able to remove each assembly separately.

In cases where separate units are provided, the rule appears to be that the gearbox is removed by lifting it instead of lowering it—certain Dennis designs 1,ing exceptions. As many maintenance engineers are in favour of lowering it, this point might be worthy of further consideration.

The same thing may be said of petrol tanks, the majority of which could be lowered for removal, but in several instances they were so arranged that they would have to be raised for removal.

The great variation of ideas as to the size and strength of steering-box mountings struck me, as in some instances a mountainous structure was provided, whilst in others a boss extending from the box appeared to be the only means of holding this assembly to the chassis. In some cases this appeared to be but a flimsy means of securing a most important part; should the boss break off the box would lose its means of support, and although the spindle might prevent the whole box from coming adrift, such a breakage would seriously disconcert a driver, with the result that an accident might happen.

Driving the magneto in line with the dynamo, using the armature of the

latter as ft shaft, is, no doubt, a method of simplifying design and reducing the number of parts, but it is well known that dynamos at times require attention, and unless a shaft be provided which

• can be inserted in its place, the holding up of the vehicle for many days may he necessary. I noticed that in the ease of the Dennis a spare shaft for this purpose is provided.

Owing to the attention which has recently been paid to the importance of providing means whereby the possibility of an outbreak of fire is reduced to a minimum, it struck me as strange that only a small percentage of the chassis shown had any provision for draining away petrol that might escape from the carburetter.

Grease-gun lubrication is almost the rule, but in many instances the nipples are uncovhed, so that there is a possibility of foreign matter getting into the pipes—a fatal thing with this class of lubrication. In some cases care has been taken to provide efficient covers for the nipples.

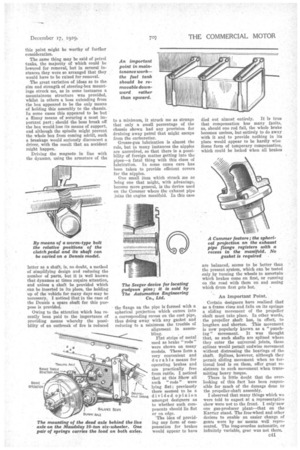

One small item which struck me as being one that might, with advantage, become more general, is the device used on the Commer where the exhaust pipe joins the engine manifold. In this case the flange on the pipe is formed with a spherical projection which enters into a corresponding recess on the cast pipe, thus doing away with any gasket and reducing to a minimum the trouble of alignment in assem bling.

Flat strips of metal used as brake " rods " were shown on many models. These form a very convenient and durable means for operating brakes and are practically free ' from rattle. I noticed that at this Show all such "rods" were lying flat; previously there seemed to be a divided opinion amongst designers as to whether such com ponents should lie flat or on edge.

The idea of providing any form of compensation for brakes would appear to have

died out almost entirely. It is true that compensation has many faults, as, should one rod fail, the whole brake becomes useless, but entirely to do away with it and to provide nothing in its place would appear to be hardly wise Some form of temporary compensation, which could be locked when all brakes are balanced, seems to be better than the present system, which can be tested only by turning the wheels to ascertain which brakes come on first, or running on the road with them on and seeing Nvhich drum first gets hot.

An Important Point.

Certain designers have realized that as a frame rises and falls on its springs a sliding movement of the propeller shaft must take place. In other words, the propeller shaft has in effect, to lengthen and shorten. This movement is now popularly known as a "punching" movement. It was thought that, as such shafts are splined where they enter the universal joints, these splines would permit endwise movement without distressing the bearings of the shaft Splines, however, although they permit sliding movement when no tortional load is on them, offer great resistance to such movement when transmitting heavy torque.

There is little doubt that the overlooking of this fact has been responsible for mach of the damage done to the propeller-shaft assembly.

I observed that many things which we were told to expect at a representative show were not to the front. I only saw one gas-producer plant—that on the Karrier stand. The free-wheel and other devices to enable an easier change of gears were by no means well represented. The long-overdue automatic, or infinitely variable, gear was not there.