The Use of Chromium as a Bearing Metal

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Successful Results Obtained from Parts Treated by the Fescol Process

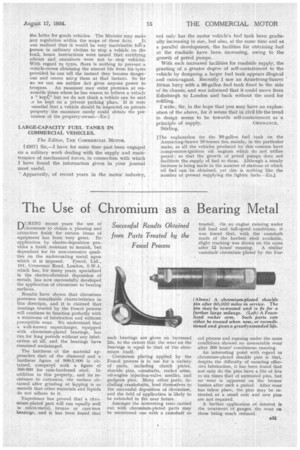

DURING recent years the use of L./chromium to obtain a pleasing and attractive finish for certain items of equipment has been very great. Its application by electro-deposition provides a finish resistant to tarnish, but dependent for its non-corrosive qualities on the undercoating metal upon which it is imposed. Fescol, Ltd., 101, Grosvenor Road, Lon-don, S.W.1, which has, for many years, specialized in the electro-chemical deposition of metals, has now successfully developed the application of chromium to bearing surfaces.

Results have shown that chromium possesses remarkable characteristics in this direction, and it is claimed that bearings treated by the Fescol process will continue to function perfectly with a minimum of lubrication and without perceptible wear. We understand that a well-known supercharger, equipped with chromium-plated bearings, has run for long periods without any lubrication at all, and the bearings have remained undamaged.

The hardness of the material approaches that of the diamond and a hardness figure of 900-1000 is obtained, compared with a figure of 500-590 for case-hardened steel. In addition to this property, and its resistance to corrosion, the surface obtained after grinding or lapping is so smooth that other materials and liquids do not adhere to it.

Experience has .proved that a chromiu.m-plated part will run equally well in .white-metal, bronze or cast-iron beatings, and it has been found that

such bearings are given an increased life, to the extent that the wear on the bearings is equal to that of the chromium itself.

Chromium plating applied by the Fescol process is in use for a variety of parts, including clutch plates, shackle pins, camshafts, rocker arms, oil-engine injection-valve needles, and gudgeon pins. Many other parts, including crankshafts, lend themselves to the successful deposition of chromium, and the field of application is likely to be extended in the near future.

Amongst the interesting tests carried out with chromium-plated parts may be mentioned one with a camshaft so

treated. On an engine running under full load and full-speed conditions, it was found that, with the camshaft made of the hardest steel available, slight tracking was shown on the cams

after 12 hours running. A similar camshaft chromium plated by the Fes col process and running under the same conditions showed no measurable wear after 300 hours' continuous running.

An interesting point with regard to chromium-plated shackle pins is that, despite the difficulty of ensuring effective lubrication, it has been found that not only do the pins have a life of five to six times that of untreated pins, but no wear is apparent on the bronze bushes after such a period. After wear has taken place, the pins may be retreated at a small cost and new pins are not required.

A further application of interest is the treatment of gauges, the wear on these being much reduced.