Petrol -enginedTramcars.

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

Successful Application of English-built Engines and Gearboxes to Indian Public-service Tramcars.

The enormous cost of laying down permanent way with bonded rails, and for the installation of live wire conduits or overhead trolley wires for electric tramcars, is at last being viewed by many tramway engineers as unnecessary and unwarranted. Petrol tramcars, which do not require bonded rails or other special track equipment, are now being extensively used in various parts of the world, and reference to some of the more important of these have been made in pages of this journal during the past few years. At home, one of the most-important petrol tramway installations is that at the White City where StrakerSquire trams are run in daily service. Abroad numerous examples of the petrol engine's adoption for tramcar work may be found. An important example abroad, in which Leyland tramcars are concerned, is that of this year's installation at Pernambuco, Brazil. Then there is the petrol-electric rail-coach for Central South Africa, which was illustrated and described in our issue of the 27th ulto.

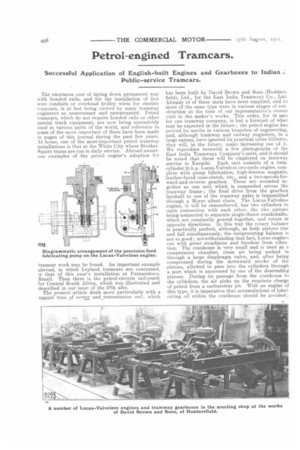

The present article deals more particularly with a smckial type _of power and_transmission unit, which has been built by David Brown and Sons (Huddersfield), Ltd., for the East India Tramcays Co., Ltd. Already 18 of these units have been supplied, and 24 more of the same type were in various stages of construction at the time of our representative's recent visit to the maker's works. This order, for 42 sets for one tramway company, is but a forecast of what may be expected in the future ; the petrol engine has proved its merits in various branches of engineering, and, although tramway and railway engineers, to a large extent, have ignored its practical value hitherto, they will, in the future, make increasing use of it. We reproduce herewith a few photographs of the East India Tramways Company's units, and it should be noted that these will be employed on tramway service in Karachi. Each unit consists of a twincylinder 25 h. p. Lucas-Valveless two-cycle engine, complete with pump lubrication, high-tension magneto, leather-faced cone-clutch, etc, and a two-speeds-forward-and-reverse gearbox. These are mounted together as one unit which is suspended across the tramway frame ; the final drive from the gearbox layshaft to one of the tramway axles is transmitted through a Morse silent chain. The Lucas-Valveless engine, it will be remembered, has two cylinders in open connection with each other, the two pistons being connected to separate single-throw crankshafts, which are constantly geared together, and rotate in opposite directions. In this way the rotary balance is practically perfect, although,. as both pistons rise and fall simultaneously, the reciprocating balance is not so good ; notwithstanding that fact, Lucas engines run with great steadiness and freedom from vibra tion. The crankcase is very small and is used as a compression chamber, clean air being sucked in through a large diaphragm valve, and, after being compressed during the downward stroke of the pistons, allowed to pass into the cylinders through a port which is uncovered by one of the descending pistons. During its passage from the crankcase to the cylinders, the air picks up the requisite charge of petrol from a carburetter jet. With an engine of this type, it is imperative that accumulations of lubricating oil within the crankcase should be avoided ; otherwise ignition troubles will ensue, because some of the churned oil will be carried into the cylinders. In order to avoid this trouble, the designer of the Lucas engine has resorted to a precision method for the lubricating of the working parts of the engine, and one of our illustrations shows two views of the mechanical lubricator which is employed. In this lubricator, a cam (F) is driven through worm gearing from one of the crankshafts, and the cam transmits an intermittent reciprocating motion to the plunger (C), through the medium of a bell-crank lever ; meanwhile, the chamber in which the plunger (C) operates is being rotated by a worinwheel (C), so as to bring the delivery port in the header (A) in juxtaposition with one of a number of ports in the distributing piece (B), whence the oil flows to the engine bearings and other parts at which lubrication is required. The drawing which we reproduce merely shows the pump in diagrammatic form ; its actual form is varied according to particular requirements. In the engines for Karachi, the pump is arranged within the oil reservoir and the four delivery pipes are led out from the bottom, the pump mechanism being inverted.

The gearbox, which is the subject of a patent taken out by Mr. J. D. Abbott, the managing director of the East India Tramways Co., is a very sturdy and straightforward job ; it has two top shafts, one of which is coupled to the clutch-shaft. It provides for two speeds in each direction.

We reproduce a photograph showing one of these cars in running order. The first car has now been in service for over 12 months and has run a distance exceeding 18,000 miles. As a result of six months' working with five cars to which some of the first batch of engines and gears were fitted, the aggregate mileage was nearly 45,000, whilst the average miles per car during the period was 9,810, and the number of passengers carried 523,405.. The net running cost per car mile of these petrol-engmed tramcars is extremely low : the average for six months for petrol, oil, drivers and conductors' wages, repairs and maintenance of cars, etc., is given us as 21d. per car-mile. During the same period the earnings per car-mile were 91d. To the 2d., of course, must be added the cost of track maintenance, depreciation and overhead charges, etc., which bring up the .total costs to 4:d. The power and transmission units, although built by David Brown and Sons, Ltd., are being supplied to the order of the Motor Rail and Tramway Co., Ltd., of 79., Lombard Street, E.C. (which company owns the Simplex tramcar patents), to which address all inquiries respecting those patents should be forwarded. The cars weigh 3 tons 5 cwt. each, and seating accommodation is provided for 46 passengers.

David Brown and Sons, Ltd., is sole manufacturer of the Lucas-Valveless engines and has the exclusive handling of them for commercial purposes. This is one of the most-irnportant orders for that type of engine which the company has executed. It will be remembered that the making of Lucas engines is but a small department in David Brown and Sons' extensive factory, at Lockwood. Worm-gears, bevel-gears, spur-gears, and, in fact, gear-wheels of all description, are manufactured at Huddersfield by the hundredthousand every year, and it is very satisfactory to not e that a large percentage of these gears is sent out to the U.S.A., notwithstanding that country's enormously-high tariff. The manufacture of machine tools for the production of tooth-geating is another very large branch of David Brown's business, and we Forecast that, when American motor manufacturers become tired of paying high tariffs on manufactured gears, they will install special machines, manufactured in David Brown's works, for the production of their own gear-wheels. This American patronage of English gear-makers, although applying chiefly to worm and . skew gears, is by no means confined to those particular types, and is very widespread ; it is remarkable evidence of good workmanship.