HINTS ON MAINTENANCE.

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

How Tight Morris Drums Can Be Removed. The Attention Required by Electric Vehicles. Securing a Thornycroft Gearbox.

Removing Morris Rear-brake Drums which ate Difficult to Withdraw.

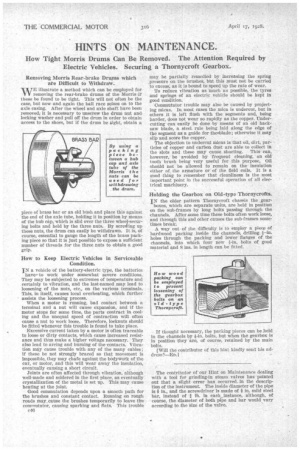

WE illustrate a method which can be employed for removing the rear-brake drums of the Morris if these be found to be tight. This will not often be the ease, but now and again the ball race seizes on to the axle casing. After the wheel and axle shaft have been removed; it is necessary to unscrew the drum nut and locking washer and pull off the drum in order to obtain access to the shoes, but if the drum be tight, obtain a

piece of brass bar or an old bush and place this against the end of the axle tube, holding it in position by means of the hub cap,which is slid over the three wheel-securing bolts and held by the three nuts. By scre4ing IIP these nuts, the drum can easily be withdrawn. It is, of course, essential to gauge the length of the brass packing piece so that it is just possible to expose a sufficient number of threads for the three nuts to obtain a good grip.

How to Keep Electric Vehicles in Serviceable Condition.

IN a vehicle of the battery-electric type, the batteries 'haves to work under somewhat severe conditions. They may be subjected to extremes of temperature and certainly to vibration, and the last-named may lead to loosening of the nuts, etc., on the various terminals. This, in itself, causes local overheating, which further assists the loosening process.

When a motor is running, bad contact between a terminal and a nut will cause expansion, and if the motor stops for some time, the parts contract in cooling and the unequal speed of contraction will often cause a nut to work loose. Therefore, locknuts should be fitted whenever this trouble is found to take place.

Excessive current taken by a motor is often traceable to loose or dirty contacts, which cause increased resist

ance and thus make a higher voltage necessary. They

also lead to arcing and burning of the contacts. Vibration may cause trouble with any of the many cables; if these be not strongly braced so that movement is impossible, they may chafe against the bodywork of the car, or motor, and this will wear away the insulation, eventually causing a short circuit.

Joints are often affected through vibration, although well-made and soldered in the first place, as eventually crystallization of the metal is set up. This may cause heating at the joint.

Good commutation depends upon a smooth path for the brushes and constant contact. Running on rough roads may cause the brushes temporarily to leave the commutator, causing sparking anti flats. This trouble

may be partially remedied by increasing the spring _pressure on the brushes, but this must not be carried to excess, as it is bound to speed up the rate of wear.

To reduce vibration as -much as possible, the tyres and springs of an electric vehicle should be kept in good condition.

Commutator trouble may also be caused by projecting micas. In most cases the mica is undercut, but in others it is left flush with the segments and, being harder, does not wear so rapidly as the copper. Undercutting can easily be done by means of an old hacksaw blade, a steel rule being laid along the edge of the segment as a guide for theeblade ; otherwise it may slip and score the copper.

The objection to undercut micas is that oil, dirt, parfides of copper and carbon dust are able • to collect in the slots and these may cause shorting. This can, however, be avoided by frequent cleaning, " an old 100th brush being very useful for this purpose. Oil should not be allowed to remain On the insulation either of the armature or of the field coils. It is a good thing to remember that cleanliness is the most important point in the successful operation of all electrical machinery.

Holding the Gearbox on Old-type Thornycrofts.

IN the older pattern Thornycroft chassis the gear

boxes, which are separate units, are held in position on the sub-frames by long bolts passing through the channels. After some time these bolts often work loose, and through this and other causes the sub-frames sometimes break.

A way out of the difficulty is to employ a piece of hardwood packing inside the channels, drilling 3--in. holes through the packing and lower flanges of the channels, into which four new 4-in, bolts of good material and 8 ins, in length can be fitted.

If thought necessary, the packing pieces can beheld in the channels by bolts, but when the gearbox is in position they are, of course, retained by the main bolts.

{Will the contributor of this hint kindly send his address ?—En.} The contributor of our Hint on Maintenance dealing with a tool for grinding-in steam valves has pointed out that a slight error has occurred. in the description of the instrument. The inside diameter of the pipe is * in., and the screwdriver is made of * in. mild steel bar, instead of 2in. in each instance, although, of course, the diameter of both plim and bar would vary according to the size of the valve.