NOVEL CONSTRUCTION IN A NEW SIX-WHEELER.

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

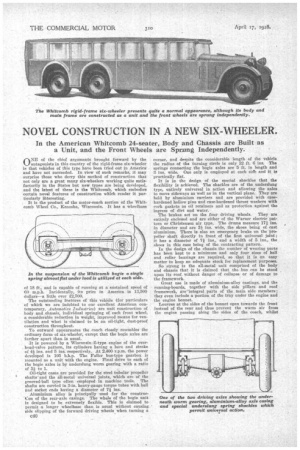

In the American Whitcomb 24-seater, Body and Chassis are Built as a Unit, and the Front Wheels are Sprung Independently.

(\NE of the chief arguments brought forward by the 1../antagonists in this country of the rigid-frame six-wheeler is that vehicles of this type have been tried out in America and have not succeeded. In view of such remarks, it may surprise those who decry this method of construction that not only are a great many six-wheelers working quite satisfactorily in the States but new types are being developed, and the latest of these is the Whitcomb, which embodies certain novel features of construction which render it particularly ihteresting.

• It is the product of the motor-coach section of the Whitcomb Wheel Co., Kenosha, Wisconsin. It has a wheelbase of 18 ft., and is capable of running at a sustained speed of 60 m.p.h. Incidentally, its price in America is 13,500 dollars—a little over £2,700.

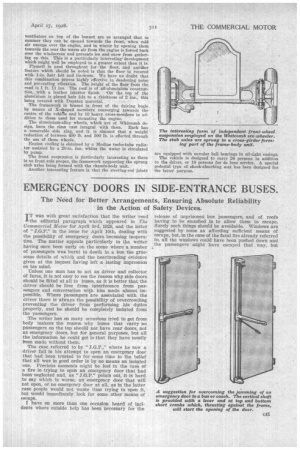

The outstanding features of this vehicle (for particulars of which we are indebted to our excellent American contemporary, -4utornotive ndastrie-s) are unit construction of body and, chassis, individual springing of each front wheel, a considerable reduction in weight, improved means for ventilation and what is claimed to be an oil-tight, dust-proof construction throughout.

To outward appearances the condi closely resembles the ordinary form of six-wheeler, -except that the bogie axles are farther apart than is usual.

It is powered by a Wisconsin .Z-type engine of the over

• head-valve pattern, its cylinders having a bore and stroke of 4i ins. and 5 ins. respectively. At 2,400 r.p.m. the power developed is 105 b.h.p. The Fuller bus-type gearbox is mounted as a unit with the engine. Final drive to each of the bogie axles is by underslung worm gearing with a ratio of 5* to 1.

Oil-tight cases are provided for the steel tubular propeller shafts and the all-metal universal joints, which are of the grooved-ball type often employed in machine tools. The shafts are carried in 3-in, heavy-gauge torque tubes with ball and socket ends having a diameter of 71 ins.

Aluminium alloy is principally used for the construct:on of the rear-axle casino's. The whole of the bogie unit is designed to be extremely flexible. This is claimed to permit a longer wheelbase than is usual without causing side slipping of the forward driving wheels when turning a C40 corner, and despite the considerable length of the vehicle the radius of the turning circle is only 32 ft. 6 ins. The springs connecting the bogie axles are 5 ft. in length and 3 ins. wide. One only is employed at each sidt and it is practically flat.

It is in the design of the special shackles that the flexibility is achieved. The shackles are of the underslung type, entirely universal in action and allowing the axles to move sideways as well as in the vertical plane. They are held by aluminium carriers and are provided with casehardened hollow pins and case-hardened thrust washers with cork gaskets as oil retainers and as protection against the ingress of dirt and water.

The brakes act on the four driving wheels. They are entirely enclosed and are either of the Warner electric pattern or Christensen air type. The drums measure 171 ins. in diameter and are 3* ins, wide, the shoes being of cast aluminium. There is also an emergency brake on the propeller shaft directly in front of the first universal joint; it has a diameter of 7i ins., and a width of 5 ins., the shoes in this case being of the contracting pattern.

In the design of the chassis the number of wearing parts has been kept to a minimum and only four sizes of ball and roller bearings are required, so that it is an easy matter to keep an adequate stock for replacement purposes.

So strong is the all-metal unit comprised of the body and chassis that it is claimed that the bus can be stood upon its roof without danger of collapse or of damage to the framework.

Great use is made of aluminium-alloy castings, and the running-boards, together with the side pilrars and roof framework, are integral parts of the main side members ; they even include a portion of the tray under the engine and the engine bonnet.

Louvres at the sides of the bonnet open towards the front instead of the rear and thus prevent the warm air from the engine passing along the sides of the coach, whilst ventilators on top of the bonnet are so arranged that in summer they can be opened towards the front, when cold air sweeps over the engine, and in winter by opening them towards the rear the warm air from the engine is forced back over the windscreen and prevents ice and snow from gathering on this. This is a particularly interesting development which might well be employed to a greater extent than it is.

Plymetl is used throughout for the floor, and another feature which should be noted is that the floor is covered with 1-in, hair felt and linoleum. We have no doubt that this combination proves highly effective in deadening noise and preventing vibration. The height of the floor from the road is 1 ft. 11 ins. The roof is of all-aluminium construction, with a leather interior finish. On the top of the aluminium is placed hair felt to a thickness of 2 ins., this being covered with Duratex material.

The framework is braced in front of the driving bogie by means of X-shaped members converging towards the centre of the vehiae and by 10 heavy cross-members in addition to those used for mounting the engine.

The aluminium-alloy wheels, which are of Whitcomb design, have the rims cast integral with them. Each has a removable side ring, and it is claimed that a weight reduction of between 450 lb. and 500 lb. is effected through the use of these wheels.

Engine cooling is obtained by a Modine turbo-tube radiator assisted by a 20-in. fan, whilst the water is circulated by pump.

The front suspension is particularly interesting as there is no front axle proper, the framework supporting the sprung stub axles being formed with the chassis-body unit.

Another interesting feature is that the steering-rod joints are equipped with annular ball bearings in oil-tight casings.

The vehicle is designed to carry 24 persons in addition to the driver, or 18 persons for de luxe service. A special pedestal type of shock-absorbing seat has been designed for the latter purpose.