A Visit to the GARDNER WORKS T 0 those interested in

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

the development of the oil engine, a visit to the Barton Hall Engine Works of Norris, Henty and Gardners, Ltd., at Patricroft, Lancashire, would give much food for thought, and would probably astonish anyone inclined to doubt the future of the compression-ignition power unit for road transport. The company emploYs close on 1,000 workpeople. Of course, a good many engines are built for marine and other purposes, but the majority is now for road vehicles, and during .our tour of the works we saw 43 vehicle engines in course of erection, representing buf little more than a week's output.

In the test shop there are 15 Fronde dynamometer sets for running in the engines under power. Incidentally, each engine runs for 16 working hours, of which the final hour Is at its maximum power output. Much of the time during the running-in is spent in checking the consumption at various speeds, and no engine is permitted to leave for service unless it gives on its tests results below .385 lb. per ii.h.p.-hour, equal to .365 pt. at .86 specific gravity. These engines give extraordinarily little vibration, even at speeds up to 2,200 r.p.m., as we checked by resting a hand on the cylinders of a fivecylindered unit when it was running at this number of revolutions. One reason for this is that in the compressionignition engine there is no mis-firing whatever, the charge simply must burn, whereas in the petrol engine mis-firing can quite easily occur, and this is responsible for breaking up many racing petrol engines.

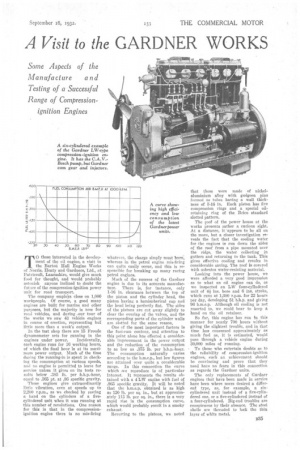

Much of the success of the Gardner engine is due to its accurate manufacture. There is, for instance, only 1-16 in. clearance between the top of the piston and the cylinder head, the piston having a hemispherical cup and the head being perfectly flat. The sides of the pistons are cut away slightly to clear the overlap of the valves, and the corresponding parts of the cylinder walls are slotted for the same reason. One of the most important factors is the fuel-cam contour, and attention to this point alone has effected a eon eiderable improvement in the power output and the reduction of the consumption to as low as .375 lb. per b.h.p.-hour. The consumption naturally varies according to the b.m.e.p., but low figures are attained over quite a considerable range. In this connection the curve which ,we reproduce is of particular interest. It represents the results obtained with a 4LW engine with fuel of .865 specific gravity. It will be noted that the b.m.e.p. obtained is as high as 120 lb. per sq. in., but at approximately 115 lb. per sq. in., there is a very rapid rise in the consumption curve, which would probably result in a smoky exhaust.

Reverting to the pistons, we noted

that these were made of nickelaluminium alloy with gudgeon pins formed as tubes having a wall thickness of 3-16 in. Each piston has five compression rings and a special oilretaining ring of the Brien standard slatted pattern.

The roof of the power house at the works presents rather a curious sight. At a distance, it "appears to be all on the move, but a closer investigation reveals the fact that the cooling water for the, engines is run down the sides of the roof from a pipe mounted over the ridge, the water collecting in gutters and returning to the tank. This gives effective cooling and results in considerable saving, The roof Is covered With asbestos water-resisting material.

Looking into the power house, we were afforded a very good impression as to what an oil engine can do, as we inspected an LW fouticylitidered unit of 41 ins. bore and 6 ins, stroke, which runs at 1,300 r.p.m. for 22 hours per day, developing 51 b.h.p. and giving 06 b.m.e.p. Although oil cooling is not resorted to, we could bear to keep a hand on the oil retainer.

So far, this engine has run In this manner for nearly 700 hours without giving the slightest trouble, and in that time has consumed approximately as much fuel as, it is estimated, would pass through a vehicle engine during 30,000 miles of running.

To those who entertain doubts as to the reliability of compression-ignition engines, such an achievement should be convincing and prove that they need have no fears in this connection as regards the Gardner units. The only replacements of Gardner engines that have been made in service have been where users desired a different type, as, for example a six cylindered unit instead of a example, one, or a five-cylindered instead of a too r-cylindered. Big-end troubles are conspicuous by their absence. The steel 8hells are threaded to lock the thin layer of white metal.