THE STORAGE OF PETROL.

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Steel Barrel System.

IN OUR PREVIOUS . article on the storage of petrol, .we described the Bowser system. In this article we will describe the system used by the Steel Barrel Co., Ltd., of Uxbridge, Middlesex, examples of which are in use all over the country, both by private concerns and by the Government. In this system also the petrol is contained in tanks sunk into the ground and embedded in concrete. They are made of sufficient thickness to withstand the weight of heavily-laden vehicles. The chief points about them is that they are welded at all joints, and that they are thoroughly galvanized inside and outside after manufacture to combat the corrosive action of petrol or benzole, both of which are liable to rust plain iron or steel, which not only ruins the tanks, but renders the spirit impure. As usually arranged, the storage tanks are sunk into the ground in a vertical position, and are of 300 to 10,000 gallons capacity, one or more tanks being used, according to the total storage capacity required. Each tank is provided with cl, manhole 18 ins, diameter in the centre of the top, which is provided with an asbestos washer coated with shellac varnish. A filling pipe extends to within about 4 ins, of the bottom of the tank, thus avoiding, so far as possible, the vaporizing of spirit owing to excessive turbulence Whilst filling. In the upper portion of this filling pipe is fitted a brass wire gauze strainer. The point of filling is above ground to prevent risk of water entering, and the pipe is provided with a gun-metal cap rendered air-tight by a leather washer. The filling pipe can be so arranged that the hose pipe accompanying the suppliers' road tank wagon can he screwed on so that the tank may be filled under seal.

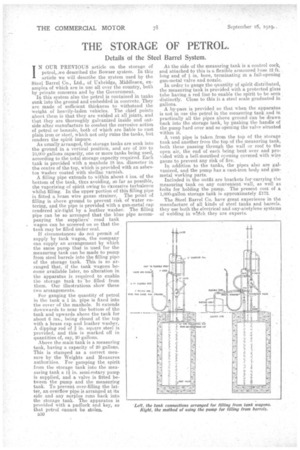

If circumstances do. not permit of supply by tank wagon, the company can supply an arrangement by which the same pump that is usedfor the measuring tank can be made to pump from steel barrels into the filling pipe, of the storage tank. This is so arranged that, if the tank wagons become available later, no alteration in the apparatus is required to enable the storage tank to 'be filled from therm Our illustrations show these two arrangements.

For gauging the quantity of petrol in the tank a 1 in. pipe. is fixed into the cover of the manhole. It extends downwards to near the bottom of the tank and upwards above, the tank for about 6 ins., being closed at the top with a brass cap and leather washer, A dipping rod of in. square steel is provided, and this is marked off in quantities of, say, 20 gallons.

Above the main tank is a measuring tank, having a capacity of 20 gallons. This is stamped as a correct measure by the Weights and Measures authorities. For pumping the spirit from the storage tank into the measuring tank a 1 in, semi-rotary pump is supplied, and a valve is fitted between the pump and the measuring tank. To prevent over-filling the latter, an overflow pipe is arranged at its side and any surplus runs back into the storage tank. The• apparatus is provided with a padlock and key, so that petrol cannot be stolen.

a30 At the side of the measuring tank is a control cock, and attached to this is a flexible armoured hose 12 ft. long and of 1 in. bore, terminating in a full-opening gun-metal valve and nozzle. In order to gauge the quantity of spirit distributed, the measuring tank is provided with a protected glass tube having a red line to enable the spirit to be seen • distinctly. Close to this is a steel scale graduated in gallons.

A by-pass is provided so that when the apparatus. is not in use the petrol in the measuring tank and in practically all the pipes above ground can be drawn ,back into the storage tank, by pushing the handle of the pump hard over and so opening the valve situated within it.

A vent pipe is taken from the top of the storage tank and another from the top of the measuring tank, both these passing through the wail or roof to the open air, the end of each being bent over and provided with a bell-mouthed opening covered with wise gauze to prevent any risk of fire.

In addition to the tanks, the pipes also are galvanized, and the pump has a cast-iron body and gunmetal working parts.

Included in the outfit are brackets for the measuring tank on any convenient wall, as well as bolts for holding the pump. The present cost of a 1,000-gallon storage tank is approximately £172.

The Steel Barrel CO. have great experience in the manufacture of all kinds of steel tanks and barrels, they use boththe electrical and .oxy-acetylene systems of welding in wtich they are experts.