TURBULENCE IN THE COMBUSTION CHAMBER.

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Recently Published Patent Specifications.

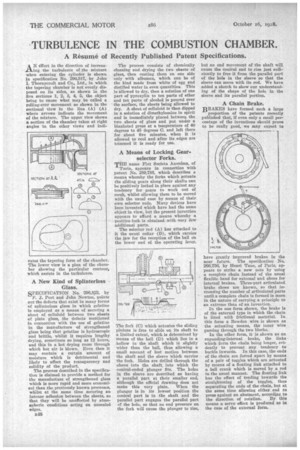

AN effort in the direction of increasing the turbulence of the mixture when entering the cylinder is shown in specification No. 296,517, by John I. Thornycroft and Co., Ltd., in which the tapering chamber is not evenly disposed on its sides, as shown in the five sections 1, 2, 3, 4, 5, the object being to cause what may be called a rolling-over movement as shown in the sectional view in the line (A) (A) where arrows indicate the movement of the mixture. The upper view shows a section of the chamber taken at right angles to the other views and indi

cotes the tapering form of the chamber. The lower vieW is a plan of the chamber showing the particular contour, which assists in the turbulence.

A New Kind of Splinterless Glass.

SPECIFICATION No. 296,825, by P. J. Port and John Newton, points out the defects that exist in many forms of splinterless glass in which gelatine is employed as a means of securing a sheet of celluloid between two sheets of plate glass, the defects mentioned in connection with the use of gelatine in the manufacture of strengthened glass being that gelatine is hydroscopic and brittle, whilst it requires lengthy drying, sometimes so long as 12 hours, and this in a hot drying room 'through which hot air is blown. Even then it may contain a certain amount of moisture which is detrimental and likely to affect the transparency and solidity of the product.

The process described in the specification is claimed to provide a method for the manufacture of strengthened glass which is more rapid and more economical than the previously known processes, whilst at the same time securing an intense adhesion between the sheets, so that they will be unaffected by atmospheric conditions acting on unsealed edges.

B18

The process consists of chemically cleaning and drying the two sheets of glass, than coating them on one side only with albumen, which can be of the kind made from white of egg and distilled water in even quantities. This is allowed to dry, then a solution of one part of pyroxylin to ten parts of ether and ten parts of alcohol is poured over the surface, the sheets being allowed to dry. A sheet of celluloid is then dipped in a solution of dimethylamine in spirit and is immediately placed between the two sheets of glass and put under a blanketed press at a temperature of 40 degrees to 45 degrees C. and left there for about five minutes, when it is allowed to cool and after its edges are trimmed it is ready for use.

A Means of Locking Gearselector Forks.

THE name Fiat Societa Anonima, of

Turin, appears in connection with patent No. 289,788, which describes a means whereby the forks which actuate the sliding gears along their shafts can be positively locked in place against any tendency for gears to work out of mesh, whilst allowing them to be moved with the usual ease by means of their own selector rods. Many devices have been invented which have had the same object in view, but the present invention appears to afford a means whereby a positive lock is obtained with very few additional parts.

The selector rod (A) has attached to it the usual collar (B), which carries the jaw for the reception of the ball on the lower end of the operating lever.

The fork (C) which actuates the sliding pinions is free to slide on its shaft to a limited extent, which is determined by means of the ball (D) which lies in a hollow in the shaft which is slightly wider than the ball, thus allowing a small amount of lost motion between the shaft and the sleeve which carries the fork. Holes are drilled through the sleeve into the shaft into which the conical-ended plunger fits. The holes in the sleeve are described as having a parallel part at their smaller end, although the official drawing does not make this very plain. When the plunger is in its lowest position the conical part is in the shaft and the parallel part engages the parallel part of the hole, so that no end pressure on the fork will cause the plunger to rise,

but an end movement of the shaft will cause the conical end to rise just sufficiently to free it from the parallel part of the hole in the sleeve so that the sleeve can move with its rod. We have added a sketch to show our understanding of the shape of the hole in the sleeve and its parallel portion.

A Chain Brake.

BRAKES have formed such a large proportion of the patents recently published that, if even only a small percentage of the inventions should prove to be really good, we may expect to

have greatly improved brakes in the near future. The specification No. 266,756, by Henri Tana, of Paris, appears to strike a new note by using• a complete chain instead of the usual flexible band for external and shoes for internal brakes. Three-part articulated brake shoes are known, so that increasing the number of articulated parts until a complete chain is formed is more in the nature of carrying a principle to an extreme than of an invention.

In the one form shown, the brake Is of the external type in which the chain is lined with frictional material. In this form a Bowden wire is shown as the actuating means, the inner wire passing through the two blocks.

In the other form, it is shown as an expanding-internal brake, the links . which form the chain being longer, evidently to prevent ally tendency to buckle inwards. In this case, the ends of the chain are forced apart by means of a pair of toggles which are actuated by means of a floating link attached to a bell crank which is moved by a rod in the usual manner. The floating link has the effect of tending towards the straightening of the toggles, thus separating the ends of the chain, but at the same time allowing either end to press against an abutment, according to

the direction of rotation. By this means a servo effect is produced as in the case of the external form.