AN EIGHT-TON SIX-WHEELER FROM SCOTLAND.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Brief Details of a New Halley Rigid-frame Model with a Six-cylindered Engine and Worm Drive.

SOMB time ago Halley Motors, Ltd., of ioker, Glasgow, brought out two rigid-frame sixwheelers intended for passenger work, one for

4 vehicles seating up •to 32 people and the other up to 36, but the company did not specialize in a goods vehicle of this type. This deficiency has, however, now been remedied and a striking 8-tonner has b een evolved.

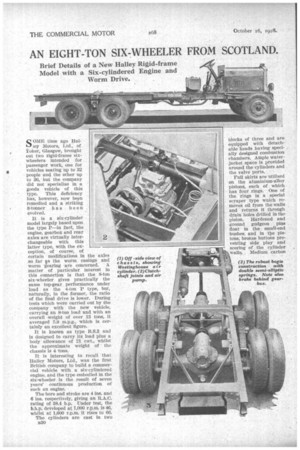

It is a six-cylinder model largely based upon the type P—in fact, the engine, gearbox and rear axles are virtually interchangeable with this latter type, with the exception, of course, of certain modifications in the axles so. far its the worm casings and worm gearing are concerned. A matter of particular interest in this connection is that the 8-ton six-wheeler gives practically the same top-gear performance under load as the 4-ton P type, but, naturally, in the former, the ratio of the final drive is lower. During tests which were carried out by the company with the new vehicle, carrying an 8-ton load and with an overall weight of over 13 tons, it averaged 5.9 m.p.g., which is certainly an excellent figure.

It is known as type B.S.3 and Is designed to carry its load plus a body allowance of 21 cwt., whilst the approximate weight of the chassis is 4 tons.

It is interesting to recall that Halley Motors, Ltd., was the first British company to build a commercial vehicle with a six-cylindered engine, and the type embodied in the six-wheeler is the result of seven years' continuous production of such an engine.

The bore and stroke are 4 ins. and 6 ins, respectively, giving an R.A.C. rating of 38.4 h.p. Under test, the h.h.p developed at 1,000 r.p.m. is 46, whilst at 1,600 r.p.rn. it rises to 66.

The cylinders are east in two 3330 blocks of three and are equipped with detachable heads having sped designed combustion chambers. Ample water. jacket space is provided around the cylinders and the valve ports.

Full skirts are utilized on the aluminium-alloy pistons, each of which has four rings. One of the rings is a special scraper type which removes oil from the walls and returns it through drain holes drilled in the piston. Hardened and ground gudgeon pins float in the small-end bushes and in tlie pistons, bronze buttons preventing side play and scoring of the cylinder walls. Medium carbon

steel is utilized for the connecting rods; these have gun-metal smallend bushes, whilst the big-ends are lined with white metal cast directly *under pressure into the rods.

The crankshaft is of chromenickel steel, to which is attached a cast-iron flywheel machined all over and carefully balanced with its clutch assembly, nickel-steel fitted bolts being employed for securing it to the crankshaft.

Driving the Engine Auxiliaries.

The valves are all at the near side. The inlet valves are of nickel steel and the exhaust valves of special heat-resisting material. Their operation is effected by mushroom tappets controlled by a camshaft driven by a silent chain. Behind the chain pinion is a skew gear for a cross-shaft which drives the water pump and magneto. The water pump is a centrifugal type made of gun-metal throughout and it is so arranged that, in the unlikely event of failure, thermosiphonic circulation can continue. The oil pump is of the gear pattern, supplying oil to troughs above the main bearings and to other's under the big-ends. The oil is twice filtered at each circulation.

Ignition is effected by a Britishbuilt magneto—usually a Simms 8.R.6—and carburation by a Zenith instrument with the induction pipe jacketed with hot water.

The crankcase is a massive aluminium casting with a base chamber carrying 11 gallons of oil. It is carried on a three-point-suspended subframe.

Cooling is effected by a gilled-tube radiator with header and bottom tanks, air being circulated by a fan driven by a Whittle belt.

A single dry-plate clutch, totally enclosed and equipped with an effident clutch stop, conveys the drive via a double fabric joint to an Independent gearbox which is slung.

at three points from tubular crossmembers. The box is a one-piece casting with a full-size lid, and the gearshafts are of nickel-chrome steel, splined and running on adjustable taper-roller bearings. The pinions are of oil-hardened nickelchrome steel, ground after treatment. Four speeds are provided, the ratios being as follow :—Top, direct ; third, 1.7 to 1; second, 2.8 to 1; first, 4.8 to 1; reverse, 6.15 ta 1. With a back-axle ratio of Sc to 1 and the engine running at 1,200 r.p.m., the vehicle speeds are as follow :—Top, 14.05 m.p.h.; third, 8.25 m.p.h.; second, 5.00 m.p.h.; first, 2.93 m.p.h.; reverse, 2.28 m.p.h.

At the back of the gearbox is a powerful hand brake with externalcontracting shoes presenting a large area of renewable friction material.

Spicer joints are provided on the propeller shaft and on the interaxle shaft which joins the tail-end of the first worm to the forward end of the second.

The Bogie Driving Axles.

Each of the rear-axle casings is a one-piece steel casting into which are pressed nickel-chrome steel tubes. The axles are connected together at each side by two semielliptic springs secured at their centre points to a trunnion block which can rodk on a heavy-section Whaler cross-member attached to the frame by strong steel brackets. On the axles themselves are spring brackets rigidly connected to the casings, and the torque reactions are conveyed to the frame through the springs, the whole arrangement of this section being of the familiar bogie type.

Cast-steel hubs are provided for the road wheels, which run on adjustable taper roller bearings and are driven by nickel-chrome shafts engaging the hubs by means of driving dogs.

The worm gearing is of the patent D.B.S. type with the worm shafts running o . taper roller bearings, this applying also to the differential assemblies.

Westinghouse Air-operated Brakes.

The vehicle is, of course, designed to run on pneumatic tyres and the road wheels are of the steel-disc pattern. The standard tyre equipment is 34-in. by 7-in, single at the front and twin, of similar dimensions, at the rear. Each wheel of the bogie has a brake drum 18 ins. in diameter, the shoes of which are expanded by Westinghouse airbrake cylinders, the pressure being obtained from a storage reservoir at the off side of the chassis frame and fed from an air compressor driven off the gearbox layshaft. An interesting feature of this compressor is that oil is delivered into its crankcase by a small separate plunger pump driven by an eccentric from the front end of the second-motion shaft and taking its supply of oil from the gearbox.

One advantage of the presence of the pump is that it can also be utilized for the inflation of the tyres, the connection, of course, being made to the reservoir at which the air is filtered to prevent the passage of oil.

Oil-tempered,silico-manganese steel is employed for the springs. These are 3 ft. 9 ins, long at the front and 4 ft. at the rear.

The chassis frame is of exceptional rigidity, the side members being rolled-steel girders 7 ins. deep with 3-in. flanges. The main crosemembers are of cast steel or rolledchannel section, the subsidiary members being solid-drawn steel tubes. Fitted bolts are utilized throughout. '

A petrol tank of 30-gallons capacity is mounted beneath the driver's Seat and is conveniently provided with a large and accessible filler cap.