iiv,PiPs,ainvel? DATA SHEET: hi•B SPRINTER 312D

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

TECHNICIAN'S TIPS

The Mercedes-Benz Sprinter was introduced last May to replace the Ti series. There are three wheelbases (3,000, 3,550 and 4,025mm), six gross weights (ranging from 2,590 to 4,600kg) and two roof heights available.

The intention was to create an attractive and practical proposition for the owner/operator. The vehicle is a completely new design and features independent front suspension with a transverse spring. The 212D, 312D and 412D versions have a significantly revised five-cylinder, 122bhp engine with turbo intercooler and direct injection.

Extended service intervals and low cost of ownership are big selling points for the Sprinter. There is no first service and oil change intervals are 22,500km/once a year. Maintenance services are every 45,000km/two years. Synthetic oil is specified.

No CFCs or toxic substances such as asbestos or cadmium are used in Sprinter construction. The vehicle is finished in low-solvent paint and over 95% of the materials used are recyclable.

To catch up on the latest service and maintenance pointers on a 312D Sprinter we consulted Rob Greatrex at Colindale-based Mercedes-Benz Car & Truck Centre.

'The battery has been relocated to the nearside of the engine bay for easier maintenance. On the previous Ti series vehicles it was found under the seat, which sometimes had to be unbolted to provide maintenance access. The new location has safety as well as practical implications gassing occur there is no times have been reduced drawn out via the dip stick drop the sound deadening

too. Should overcharging risk of driver inhalation, Service considerably. Engine oil can be aperture which saves the need to from beneath the sump. or

2 During routine maintenance keep an eye on the condition of the Poly-V belt which runs over the crankshaft, water pump and power steering pump etc. Problems with mis

alignment or seizure of any of these will cause wear. The back of the belt (the top as you look at it) will show signs of deformation if there is trouble brewing. A revised idler bush has been introduced to reduce the possibility of premature failure.

The gear lever linkage to the box has been greatly simplified

on the Sprinter. Earlier Ti models had a multi-arm, multi-joint connection which could suffer from wear and play. The new design makes a direct link to the gearbox and no maintenance is required. In addition the traditional dog-leg first gear position has been dropped in favour of a more conventional H-pattern layout. With the old system operators frequently used to pull away in second gear which greatly increased clutch wear rates.

4 This engine is entirely electronically managed. The Mercedes-Benz HHT (hand-held tester) plugs into a socket found beneath the bonnet release lever in the nearside footwell and provides the only access to current or historical fault codes. This equipment is only available to dealerships not essential for routine servicing. There is a warning light on the dash to highlight component or other electrical failure. 5 The Sprinter 312D is fitted with brake discs all round and an ABS system on some models. The discs minimise brake servicing time per corner' and enhance performance too. If brake bleeding problems ore encountered then it may be that the control unit will have to be evacuated. This is achieved by activating each circuit electronically using the HHT unit. Generally, conventional bleeding techniques should suffice.

6 The independent front suspension employs a transverse spring which can make a tempting site for a trolley jack. It has the appearance of a sturdy chassis member but is not, so be warned.

7 Rear bulbs can now be changed from inside the vehicle.

On the T1 this °percltion would have involved removing -le exterior lens.

8 The main fuse box has been relocated too. Previously it was in the nearside fooiwell but now is found on the underside of the steering column. Blade fuses are used throughout and the main relays are located under the driver's seat.

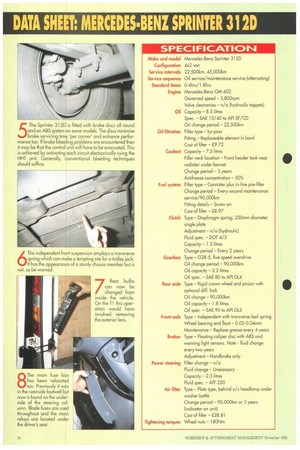

SPECIFICATIC)Ig

Mercedes-Benz Sprinter 312D

4x2 van 22,500km, 45,000km Oil service/maintenance service (alternating) 0.4hrs/1.8hrs Mercedes-Benz OM 602

Governed speed 3,800rpm Valve clearances n/a (hydraulic tappets) Capacity 8.5 litres

Spec. SAE 15/40 to API SF/CD Oil change period 22,500km Filter type by-pass

Fitting Replaceable element in bowl Cost of filter £9.72

Coolant Capacity 7.5 litres Filler neck location Front header tank near radiator under bonnet Change period 3 years Antifreeze concentration 50% Fuel system

Filter type Cannister plus in-line pre-filter Change period Every second maintenance

service/90,000km

Fitting details Screw on

Cost of filter 28.97 Clutch Type Diaphragm spring, 250mm diameter, single plate

Adjustment n/a (hydraulic)

Fluid spec. DOT 4/5

Capacity 1.2 litres Change period Every 2 years

Type G28-5, five-speed overdrive Oil change period 90,000km Oil capacity -2.2 litres Oil spec. SAE 80 to API GL4 Type Rigid crown wheel and pinion with optional diff. lock Oil change 90,000km Oil capacity 1 8 litres Oil spec. SAE 90 to API GL5

Type Independent with transverse leaf spring Wheel bearing end float 0.02-0.04mm

Maintenance Replace grease every 4 years Type Floating caliper disc with ABS and

warning light sensors. Note fluid change

every two years

AdjustmentHandbrake only

Filter change n/a Fluid change Unecessary Capacity 2.3 litres Fluid spec. ATF 220 Type Plate type, behind o/s headlamp under washer bottle Change period 90,000km or 3 years (indicator on unit) Cost of filter £28.81 Tightening torques Wheel nuts 180Nm