The Volvo Give That Little ExtrE

Page 54

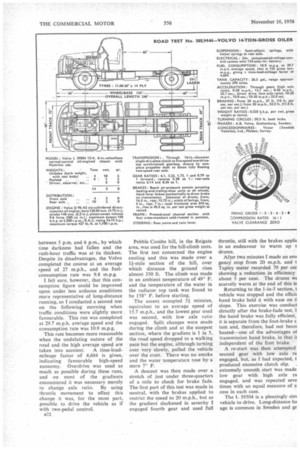

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Volvo 14tongross Chassis Tested in Britain for First Time .• Performance Compares Favourably with that of

Equivalent British Vehicles

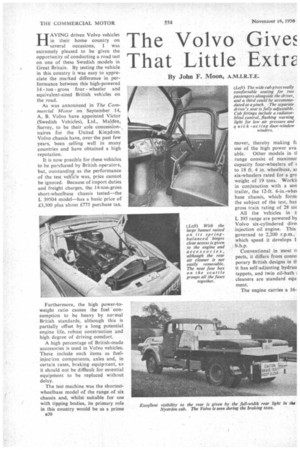

By John F. Moon, A.M.1.R.T.E. HAVING driven Volvo vehicles in their home country on several occasions, I was extremely pleased to be given the opportunity of conducting a road test on one of these Swedish models in Great Britain. By testing the vehicle in this country it was easy to appreciate the marked difference in performance between this high-powered 14 ton gross four wheeler and equivalent-sized British vehicles on the road.

As was announced in The Commercial Motor on September 14, A. B. Volvo have appointed Victor (Swedish Vehicles), Ltd., Malden, Surrey, to be their sole concession-, naires for the United Kingdom. Volvo chassis have, over the past few years, been selling well in many countries and have obtained a high reputa lion.

It is now possible for these vehicles to be purchased by British operators, but, outstanding as the performance of the test vehTcle was, price cannot be ignored. Because of import duties and freight charges, the 14-ton-gross short-wheelbase chassis tested—the L 39504 model—has a basic price of 13,300 plus about £775 purchase tax.

Furthermore, the high power-toweight ratio causes the fuel consumption to be heavy by normal British standards, although this is partially offset by a long potential engine life, robust construction and high degree of driving comfort.

A high percentage of British-made accessories is used in Volvo vehicles. These include such items as fuelinjection components, axles and, in certain cases, braking equipT.ent, so it should not be difficult for essential equipment to be replaced without delay.

The test machine was the shortestwheelbase model of the range of six chassis and, whilst suitable for use with tipping bodies, its primary role in this country would be as a prime B20 mover, thereby making ft use of the high power ava able. Other models in ti range consist of maximur capacity four-wheelers of t to 18 ft. 4 in. wheelbase, ar six-wheelers rated for a gro weight of 19 tons. Workii in conjunction with a sen trailer, the 12-ft. 6-in.-whet base chassis, which form the subject of the test, has gross train rating of 28 tot All the vehicles in t L 395 range are powered by Volvo six-cylindered diret injection oil engine. This governed to 2,200 r.p.rn., which speed it develops I b.h.p.

Conventional in most n pects, it differs from conte! porary British designs in tt it has self-adjusting hydrau tappets, and twin oil-bath cleaners are standard equ ment.

The engine carries a 16 lutch and it is mounted as a unit ith a five-speed synchromesh gearox, which has an overdrive top gear rid includes a drum-type transmison hand brake on the output shaft. he engine-gearbox unit has four asic mounting points employing ibber bobbins, but twin sandwich ibbers at the rear of the gearbox ive additional support.

An Eaton two-speed axle, with ectrically actuated gear change, is andard equipment, and in the shortheelbase version the drive to it is ken through a one-piece propeller taft. The chassis frame is built om -&-in.-thick steel pressings. The oss-members have alligator-jaw ids and cold riveting is used except here a removable cross-member' is .ovided below the engine.

Cam-operated brakes are fitted id have a large facing area. Bosch r-pressure braking equipment is riployed, the power being supplied a twin-cylindered compressor belt driven from the engine crankshaft. Ross worm-and-twin-lever steering gear gives a ratio of approximately 30 to 1, necessitating more turns of the wheel from lock to lock than is normally encountered in this country.

The test chassis, which had covered less than 300 miles, had been fitted with a temporary platform body to support the test load. Unladen, but carrying a test body, the vehicle weighed 4 tons 184 cwt. and weights were added to bring the gross figure up to 14 tons, less driver and passengers.

It was unfortunate that because of the size and shape of the weights, the rear-axle loading was 10 tons. With an equally disposed load the inter-axle ratio would have been 5 to 9.

With me throughout the test were Mr. Guy Scottorn, a director of Victor (Swedish Vehicles), Ltd., and Mr. Bert Allez, their test driver.

In view of the fine weather, 1 elected to conduct the brake tests first. These were made along Hampton Court Way, where there is a level stretch of concrete road. Emergency stops from 20 m.p.h. and 30 m.p.h. produced exceedingly good figures.

Slight delay in the system was noticeable and was confirmed by a difference of about 20 per cent. between the maximum deceleration recorded on the Tapley meter and the average deceleration shown by the stopping distances.

Light pedal pressure was required for maximum application of the brakes, and until I became accustomed to the sensitivity of the pedal reaction I experienced some difficulty in stopping smoothly during normal• traffic halts.

After the brake test, a series of acceleration times was taken. The best figures in the standing-start tests were obtained with high axle ratio engaged, using second, third and fourth gearbox ratios. The average time of 25.7 sec. recorded for the 0-30 m.p.h. test must surely be one of the highest figures achieved in this country with 14-ton-gross vehicles.

Direct-drive runs were made with low axle ratio and fourth (direct) gear engaged. Here, again, the high torque output produced exceptional figures and the power was transferred at low speed without any sign of roughness in the transmission line.

A further set of direct-drive tests was made with high axle ratio engaged. The time taken to reach 30 m.p.h. was 10 sec. longer, but again the figures were good and the transmission took up the drive smoothly.

Consumption tests were carried out along the Kingston by-pass, an 18mile out-and-return circuit being used. My first run was made

between 5 p.m. and 6 p.m., by which time darkness had fallen and the rush-hour traffic was at its thickest. Despite its disadvantages, the Volvo completed the course at an average speed of 27 m.p.h., and the fuel. consumption rate was 9.8 m.p.g.

I felt sure, however, that this consumption figure could be improved upon under less arduous conditions more representative of long-distance running, so I conducted a second test on the following morning when traffic conditions were slightly more favourable. This run was completed at 29.7 m.p.h. average speed and the consumption 'rate was 10.9 m.p.g.

This rate becomes more reasonable when the undulating nature of the road and the high average speed are

taken into account. A time-loadmileage factor of 4,604 is given, indicating favourable high-speed economy. Overdrive was used as much as possible during these runs, and on most of the gradients encountered it was necessary merely to change axle ratio. By using throttle movement to effect this change it was, for the most part, possible to drive the vehicle as if with two-pedal control.

B22 Pebble Combe hill, in the Reigate area, was used for the hill-climb tests. The first test concerned the engine cooling and this was made over a li-mile section of the hill, over which distance the ground rises almost 350 ft. The climb was made in an ambient temperature of 49° F. and the temperature of the water in the radiator top tank was found to be 158° F. before starting.

The ascent occupied 5f minutes, equivalent to an average speed of 15.7 m.p.h., and the lowest gear used was second, with low axle ratio engaged. Split changes were made during the climb and at the steepest section, where the gradient is 1 in 5, the road speed dropped to a walking pace but the engine, although turning over very slowly, pulled the vehicle over the crest. There was no smoke and the water temperature rose by a mere 7° F. "

A descent was then made over a stretch of just under three-quarters of a mile to check for brake fade. The first part of this test was made in neutral, with the brakes applied to restrict the speed to 20 m.p.h., but as the gradient slackened in severity I engaged fourth gear and used full throttle, still with the brakes applit in an endeavour to warm up t drums.

After two minutes I made an emi gency stop from 20 m.p.h. and t Tapley meter recorded 70 per cer showing a reduction in efficiency about 5 per cent. The drums va scarcely warm at the end of this te Returning to the 1-in-5 section, t vehicle was stopped and the effick hand brake held it with ease on ti slope. This exercise was conduct directly after the brake-fade test, t the hand brake was fully efficient, it is separate from the foot-brake s• tern and, therefore, had not hem heated—one of the advantages of transmission hand brake, in that it independent of the foot brake.

A re-start was then attempted second gear with low axle ra engaged, but, as I had expected, t produced excessive clutch slip. . extremely smooth start was made low gear with high axle ra engaged, and was repeated' seve times with an equal measure of s, cess in each case.

The L 39504 is a pleasingly sim vehicle to drive. Long-distance ha age is common in Sweden and gr importance is placed on a comfortable cab, restful driving position and light controls. The standard cab used by Volvo is a Nystriim all-steel assembly, fully insulated and giving good all-round vision. Instrumentation is comprehensive, and includes ;Itch refinements as a braking-preswre needle on the air gauge and a ow-air-pressure flashing warning Light.

The driving seat, which is separate 'rom the two-man bench-type pasienger seat, is adjustable in six direcions. The use of normal control gives plenty of clear cab space whilst iffording maximum engine accessi)ility.

Hidden Wing

British drivers will be unaccusomed to driving behind such a large ind bulbous bonnet, which hides the lear-side wing. It is worth considerng the use of a width indicator on his wing—a common practice on the :.`ontinent. Quick-acting windowvinding mechanisms are fitted and ncourage hand signalling.

Returning to the Malden depot, ome simple maintenance tasks were arried out. Raising the bonnet to ive access to the engine occupied even seconds. There was no need D support it in the raised position, S it is carried on spring-balanced inges.

With the bonnet up, the water level was checked in five seconds and the engine-oil level verified in 20 seconds. A plug with a square socket is provided in the gearbox for level checks, and this test was carried out in 72 seconds. A key for this plug, which is provided in the tool kit, also fits the rear-axle level plug. The latter plug was removed and replaced in 16 seconds.

A steel cover protects the, two 12v. batteries, which are housed on the near-side frame member directly behind the cab. The total time taken for checking the electrolyte levels, including removal and replacement of the cover, was 21 minutes,

The twin air filters are located above the rear rocker cover and the rearmost of the filters is under the cab scuttle panel. Lifting the filter covers to verify the oil levels is simple enough, the two levels being checked in 14 minutes, but it was obvious that complete removal of the filters would be a little more difficult because of their cramped location.

It is fortunate that self-adjusting tappets are fitted, as removal of the rocker covers would be a lengthy business, in view of the position of the air cleaners and the presence of 11 securing nuts on each cover.

There are two fuel filters on the engine, but the primary one is sealed. The main filter contains felt and cloth washable elements, which were removed and replaced in just under two minutes. The injector elements are easily accessible and a check showed that all six can be removed in 12 minutes and replaced in a similar time. Fortunately, none of the elements stuck in the cylinder head during removal, no tool being provided in the tool kit for easing the elements should this occur.

No spare wheel was carried on the test vehicle, so I could not time sa wheel-change. Similarly, because the vehicle was fully laden, I considered it unfair to adjust the brakes, as in normal circumstances this operation would never be performed when the vehicle was loaded.

Safeguards Against Frost

As might be expected with a vehicle originating in a country such as Sweden, which is notable for its cold winters, comprehensive safeguards have been incorporated to avoid damage to the vehicle during cold weather. Among these may be cited a relief valve on the top of the pump, which can be opened when draining the cooling system to ensure that no water is retained within the pump itself because of air locks. A comprehensive tool kit is provided, but more spanners would be advantageous, particularly for work on the engine. No starting handle is included in the kit, neither is there provision for the use of one.