Seddon Builds a 25-seater Oiler

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

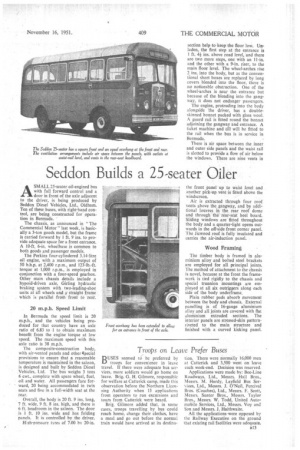

ASMALL 25-seater oil-engined bus with full forward control and a door in front of the axle adjacent to the driver, is being produced by Seddon Diesel Vehicles, Ltd., Oldham. Ten of these buses, with right-hand control, are being constructed for operation in Bermuda.

The chassis, as announced in "The Commercial Motor" last week, is basically a 3-ton goods model, but the frame is carried forward by 1 ft. 9 ins, to provide adequate space for a front entrance. A 10-ft, 6-in. wheelbase is common to both goods and passenger models.

The Perkins four-cylindered 3.14-litre oil engine, with a maximum output of 50 b.h.p. at 2,400 r.p.m., and 123-1b.-ft. torque at 1,000 r.p.m., is employed in conjunction with a four-speed gearbox. Other main chassis details include a hypoid-driven axle, Girling hydraulic braking system with two-leading-shot units at all wheels and a straight frame which is parallel from front to rear.

20 m.p.h. Speed Limit

In Bermuda the speed limit is 20 m.p.h., and the vehicles being produced for that country have an axle ratio of 6.83 to -1 to obtain maximum benefit from the engine torque at low speed. The maximum speed with this axle ratio is 38 m.p.h.

The composite-construction body, with air-vented panels and other irpecial provisions to ensure that a reasonable temperature is maintained in the saloon, is designed and built by Seddon Diesel .Vehicles, Ltd. The bus weighs 3 tons 6 cwt., complete with spare wheel, fuel, oil and water. All passengers face forward, 20 being accommodated in twin seats arid five in a full-width seat at the rear.

Overall, the body is 20 ft. 9 ins. long, 7 ft. wide, 9 ft. 8 ins, high, and there is 6 ft. headroom in the saloon. The door is 1 ft. 10 ins, wide and has folding panels. It is controlled by the driver.

Hieh-pressure tyres of 7.00 by 20-in.

section help to keep the floor low. Unladen, the first step at the entrance is 1 ft. 4i. ins, above road level, and there are two more steps, one with an 11-in, and the other with a 9-in, riser, to the main floor level. The wheel-arches rise 2 ins, into the body, but as the conventional short boxes are replaced by long covers blended into the floor, there is no noticeable obstruction. One of the wheel-arches is near the entrance but because of the blending into the gangway, it does not endanger passengers.

The engine, protruding into the body alongside 'the driver, has a doubleskinned bonnet packed with glass wool. A guard rail is fitted round the bonnet adjoining the gangway and entrance. A ticket machine and till will be fitted to the rail when the bus is in service in Bermuda.

There is air space between the inner and outer side panels and the waist rail is slotted to provide a flow of air below the windows. There are nine vents in the front panel up to waist level and another pick-up vent is fitted above the windscreen.

Air is extracted through four roof vents above the gangway, and by additional louvres in the rear roof dome and through the rear-seat heel board. Sliding windows are fitted throughout the body and a quarter-light opens outwards in the off-side front corner panel. The Jicwood roof is fully insulated and carries the air-induction panel.

Wood Framing

The timber body is framed in aluminium alloy and bolted steel brackets are employed for all principal joints. The method of attachment to the chassis is novel, because at the front the framework is tied rigidly to the chassis and special trunnion mountings are employed at all six outriggers along each side of the body underframe.

Plain rubber pads absorb movement between the body and chassis. External panelling is of 16-gauge aluminium alloy and all joints are covered with flat aluminium extruded sections. The interior panels are stressed-skin patternriveted to the main structure and finished with a curved kicking panel.