A Five-speed Gearbox for Oilers

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

The Latest Meadows Unit, which Incorporates an Over-drive, is Now Available in a Much Improved Form

A LTHOUGH the torque characteristics of an oil engine riare well suited to the requirements of larga commercial vehicles, there is a number of points in favour of utilizing a multi-speed gearbox when a power unit of this type is installed. Primarily, the higher top gear then available permits the engine speed, when traversing main roads, to be kept reasonably low, whilst a suitable ratio for freak-hill climbing can also be provided, without the differences between the ratios being too great. A satisfactor3t means for obtaining five ratios is to employ a normal four-speed gearbox with a step-up gear for "main-road work.

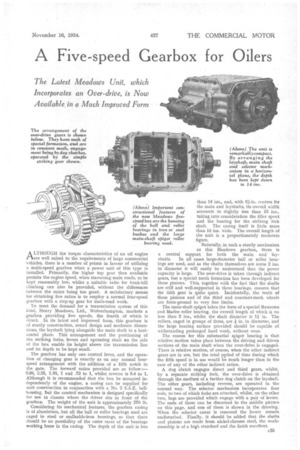

To meet the demand for a transmission system of this kind, Henry Meadows, Ltd., Wolverhampton, markets a gearbox providing five speeds, the fourth of which is direct. In its latest and improved form, this gearbox is of sturdy construction, sound design and moderate dimensions, the layshaft lying alongside the main shaft in a horizontal plane. This arrangement and the positioning of the striking forks, levers and operating shaft 4m the side of the box enable its height above the transmission line and its depth to be kept small.

The gearbox haa only one control lever, and the operation of changing gear is exactly as on any normal fourspeed arrangement with the addition of a fifth notch in the gate. The forward ratios provided are as follow :— 6.98, 3.35, 1.91, 1 and .72 to 1, whilst reverse is 9.4 to 1. Although it is recommended that the box be mounted independently of the engine, a casing can be supplied for unit construction in conjunction with a No. 2 S.A.E. bellhousing, but the control mechanism is designed specifically for use in chassis where the driver sits in front of the gearbox. The weight of the unit is approximately 370 lb.

Considering its mechanical features, the gearbox casing is of aluminium, but all the ball or roller bearings used are caged in steel or malleable-iron housings, so that there should be no possibility of the outer races of the bearings working loose in the casing. The depth of the unit is less

than 14 ins., and, with 6i-in. centres for the main and layshafts, its overall width amounts to slightly less than 33 ins., taking into consideration the filler spout and the bearing for the striking fork shaft. The casing itself is little more than 15 ins. wide. The overall length of the unit is a proportionately moderate figure.

Naturally, in. such a sturdy mechanism as this Meadows gearbox, there is a central support for both the main and lay

shafts. In all cases large-diameter ball or roller bearings are used, and as the shafts themselves are some 2 ins. in diameter it will easily be understood that the power capacity is large. The over-drive is taken through indirect gears, but a special tooth formation has been developed for these pinions. This, together with the fact that the shafts are stiff and well-supported in three bearings, ensures that the fifth gear is quite quiet. Incidentally, the teeth of these pinions and of the third and constant-mesh wheels are form-ground to very fine limits.

The main-shaft spigot takes the form of a special Ransome and Marks roller bearing, the overall length of which is no less than 2 ins., whilst the shaft diameter is 14, in. The rollers, caged in groups of three, are in. in diameter, and the large bearing surface provided shoUld be capable of withstanding prolonged hard work, without wear.

The reason for this substantial spigot bearing is that relative motion takes place between the driving and driven sections of the main shaft when the over-drive is engaged. There is relative motion, of course, when the other indirect gears are in use, but the total pTriod of time during which the fifth speed is in use would be much longer than, in the case of any of the other indirect ratios.

A dog clutch engages direct and third gears, whilst, by a separate striking fork, the over-drive is obtained through the medium of a further dog clutch on the layshaft. The other gears, including reverse, are operated in the normal. way. The selector mechanism incorporates four rods, to two of which forks are attached, whilst, on the other two, lugs are provided which engage with a pair of levers. The ends of these can be discerned in. the middle picture on this page, and one of them is shown in the drawing. When the selector cover is removed the levers remain undisturbed. Finally, it should be added that the shafts and pinions are made from nickel-chrome steel, the workmanship is of a high standard and the finish excellent.